Solidly mounted film bulk acoustic resonator adopting piezoelectric single crystal foil and preparation method thereof

A piezoelectric single crystal and thin-film bulk acoustic wave technology, applied in electrical components, impedance networks, etc., can solve problems such as the influence of foil single crystal characteristics, large damage to crystal structure integrity, etc., and achieve the effect of optimizing device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

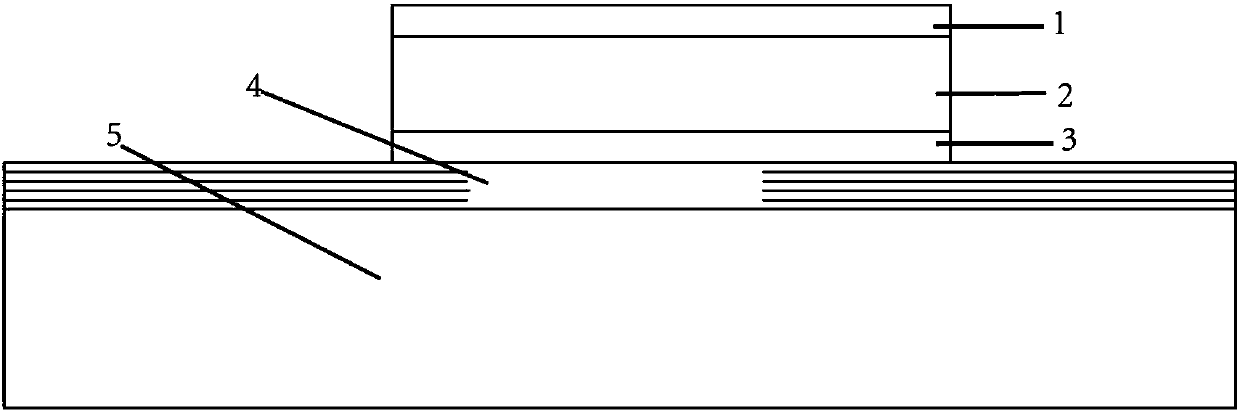

[0058] The manufacturing procedure of embodiment one is as Figure 2~Figure 8 It belongs to conventional microelectronics process technology. The invention adopts two single-sided polished wafers of the same size: a silicon substrate and a piezoelectric single crystal, and the polished surface is used as the front.

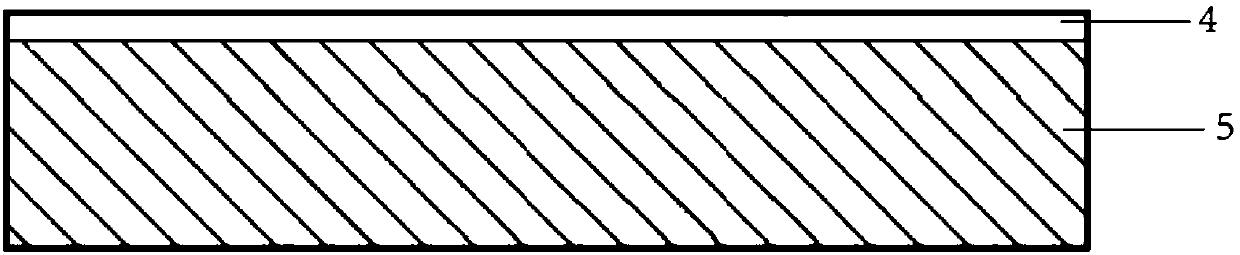

[0059] figure 2 It is the CFBAR embodiment 1 process flow 1: cleaning the substrate silicon wafer 5 and depositing the Bragg acoustic wave reflection structure layer 4 .

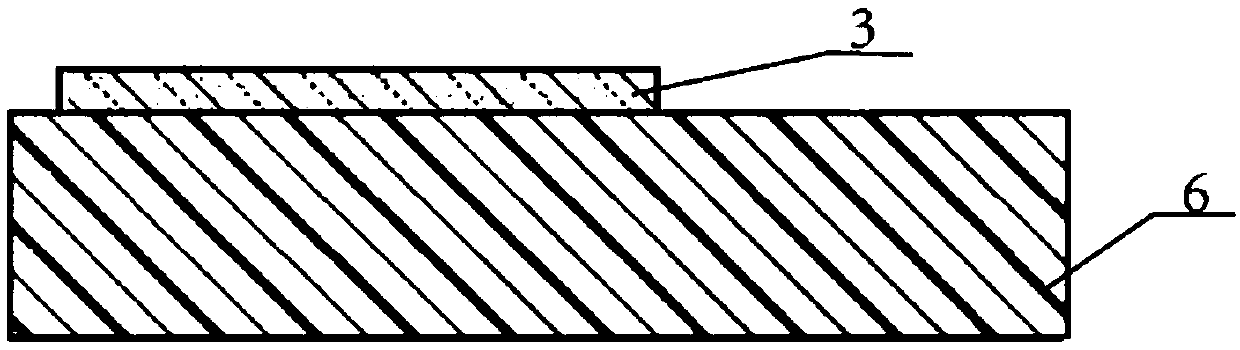

[0060] image 3 It is CFBAR embodiment 1 process flow 2: After cleaning the original piezoelectric single wafer 6, deposit a metal film on the front side, and make the lower electrode 3 by photolithography etching.

[0061] Figure 4 It is CFBAR embodiment 1 process flow 3: deposit passivation layer 7 on the front of original piezoelectric single wafer 6, generally SiO 2 Dielectric film. The thickness of the passivation layer is greater than that of the existing electrodes, so it is neces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com