Mushroom-flavored beef jerky and making method thereof

A beef jerky and mushroom-flavored technology is applied in the directions of food drying, food heat treatment, and the function of food ingredients. The effect of improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

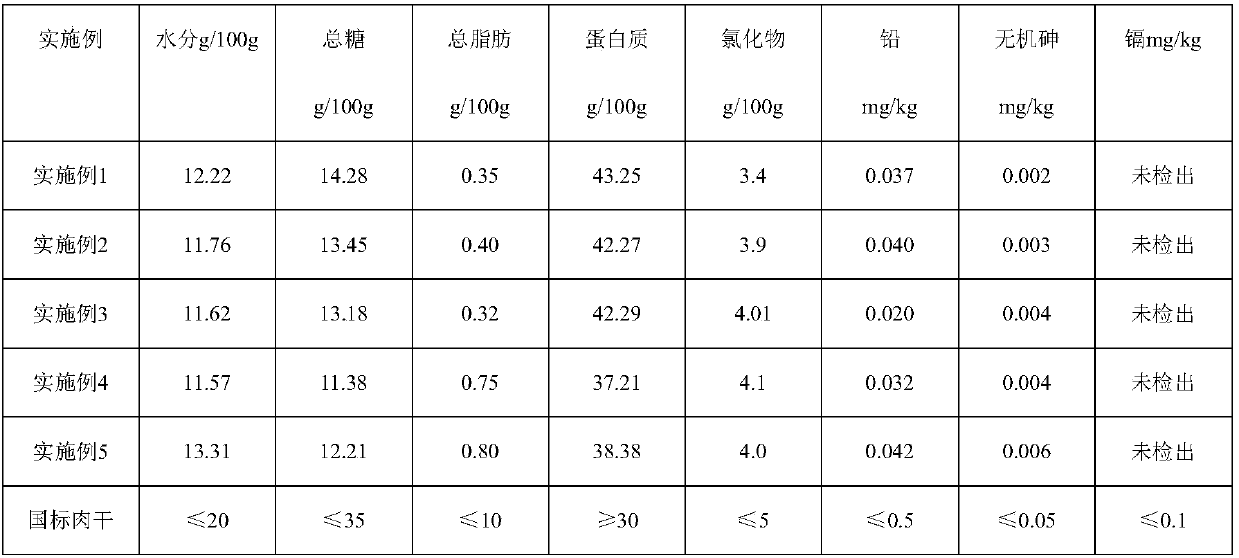

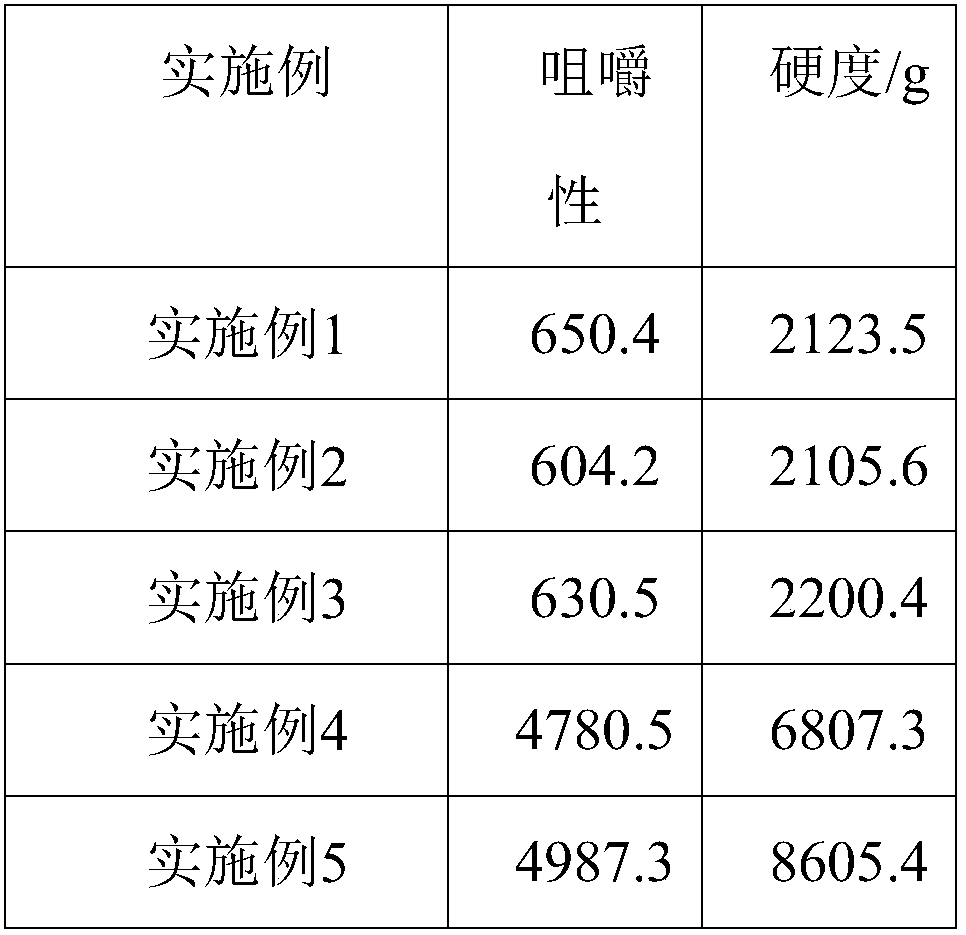

Embodiment 1

[0025] A mushroom-flavored beef jerky, comprising the following raw materials in parts by mass: 500 g of fresh yellow beef, 60 g of cooking wine, 40 g of vegetable oil, 30 g of mushroom powder, 20 g of salt, 20 g of Chinese prickly ash, 15 g of cumin, 10 g of cumin, 10 g of Angelica dahurica, and dried ginger powder 10g.

[0026] The mushroom powder includes the following raw materials in parts by mass: 20g of shiitake mushrooms, 5g of bamboo fungus, 4g of Pleurotus eryngii, 3g of ganoderma lucidum, and 1g of tea tree mushroom.

[0027] Described mushroom powder comprises the following preparation steps:

[0028] 1) Mix mushrooms, bamboo fungus, Pleurotus eryngii, Ganoderma lucidum, and tea tree mushroom, mix and grind them, add acetic acid solution to make a mixture with a water content of 50%, treat at 3.5MPa, 200°C for 5min, and obtain material 1; Acetic acid solution, the mass fraction is 5%;

[0029] 2) Material 1 was shaken on a shaking table at 70r / min for 2h, adding ...

Embodiment 2

[0040] A mushroom-flavored beef jerky, comprising the following raw materials in parts by mass: 530g of fresh yellow beef, 70g of cooking wine, 43g of vegetable oil, 31g of mushroom powder, 23g of salt, 22g of Chinese prickly ash, 17g of cumin, 14g of cumin, 11g of Angelica dahurica, dried ginger powder 11g.

[0041] The mushroom powder includes the following raw materials in parts by mass: 21g of shiitake mushrooms, 6g of bamboo fungus, 5g of Pleurotus eryngii, 3.4g of ganoderma lucidum, and 2g of tea tree mushroom.

[0042] Described mushroom powder comprises the following preparation steps:

[0043] 1) Shiitake mushrooms, bamboo fungus, Pleurotus eryngii, Ganoderma lucidum, and tea tree mushroom were mixed and crushed, and acetic acid solution was added to make a mixture with a water content of 52%. It was treated at 3.6MPa and 210°C for 5.6min to obtain material 1; Described acetic acid solution, massfraction is 5.2%;

[0044] 2) Shake material 1 on a shaker at 75r / min f...

Embodiment 3

[0055] A mushroom-flavored beef jerky, comprising the following raw materials by mass: 550g of fresh yellow beef, 80g of cooking wine, 45g of vegetable oil, 33g of mushroom powder, 25g of salt, 23g of Chinese prickly ash, 20g of cumin, 16g of cumin, 12g of Angelica dahurica, dried ginger powder 12.5g.

[0056] The mushroom powder includes the following raw materials in parts by mass: 22g of shiitake mushrooms, 8g of bamboo fungus, 5.5g of Pleurotus eryngii, 4g of ganoderma lucidum, and 3g of tea tree mushroom.

[0057] Described mushroom powder comprises the following preparation steps:

[0058] 1) Mix mushrooms, bamboo fungus, Pleurotus eryngii, Ganoderma lucidum, and tea tree mushroom, mix and grind, add acetic acid solution to make a mixture with a water content of 55%, treat at 3.8MPa, 220°C for 6 minutes, and obtain material 1; Acetic acid solution, the mass fraction is 5.6%;

[0059] 2) Shake material 1 on a shaker at 80r / min for 3 hours, add 30% ginger water of the qu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com