Black phosphorus nanosheet/platinum nanoparticle composite material as well as preparation method and application thereof

A composite material and nanosheet technology, which is applied in the field of black phosphorus nanosheet/platinum nanoparticle composite material and its preparation, can solve the problems of poor dispersion stability, low reduction ability of two-dimensional nano-doped materials, easy agglomeration, etc. low cost, simple preparation method and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] Preparation of BP nanosheets:

[0060] Black phosphorus powder samples were exfoliated by ultrasonic exfoliation to prepare ultrathin BP nanosheets.

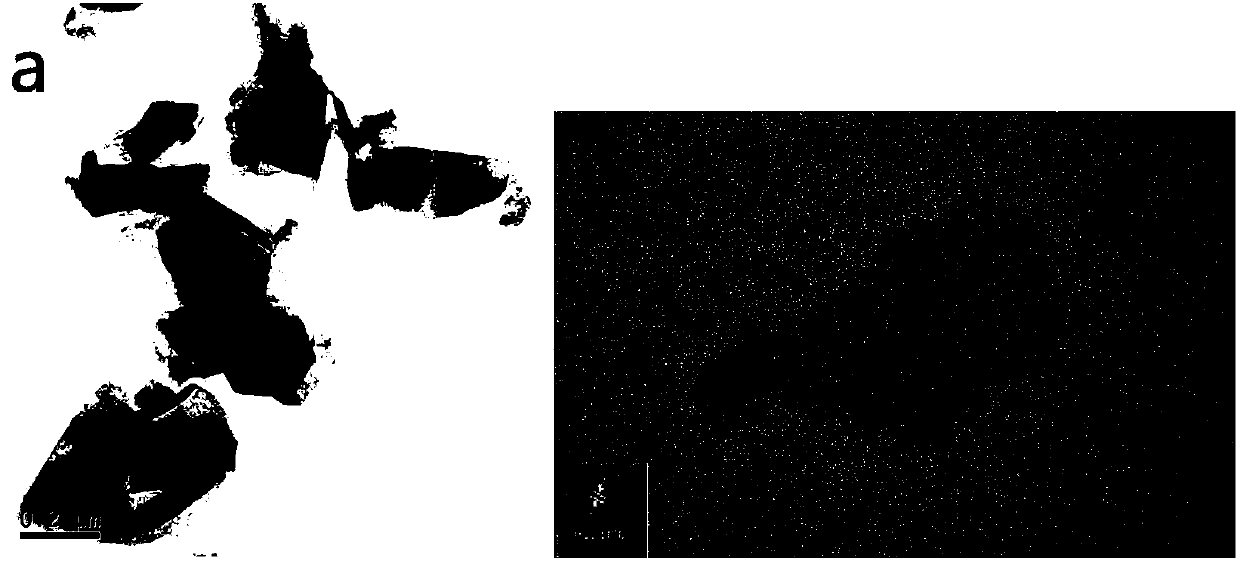

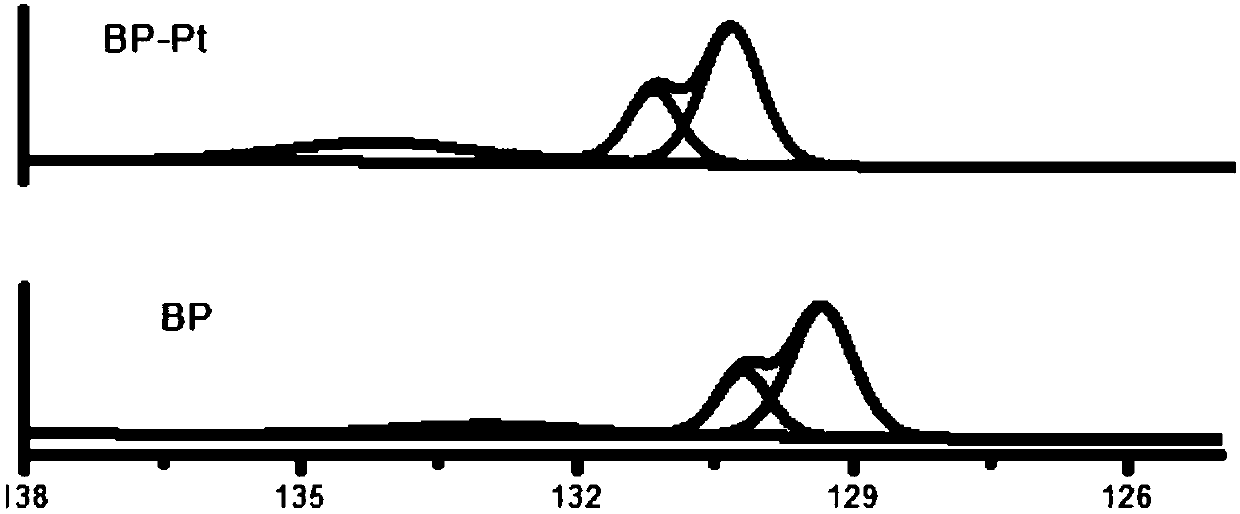

[0061] The specific process is as follows: take 30 mg of bulk black phosphorus powder and disperse it in 30 mL of saturated NaOH N-methylpyrrolidone (NMP) solution, sonicate for 10 h in an ice bath to obtain a brown suspension, then centrifuge at low speed (3000 r / min) for 10 min, To remove the unstripped black phosphorus residue, take the supernatant to obtain a brown black phosphorus nanosheet transparent liquid, use high-speed (10000r / min) centrifugation for 10min to obtain black phosphorus nanosheet precipitation, and ultrasonically disperse in the desired solution. Depend on figure 1 a It can be seen that the BP nanosheets prepared in step (1) are uniform nanosheets. The average thickness of the obtained black phosphorus nano sheet is 1nm-10nm, and the average diameter is 100nm-300nm.

Embodiment 1

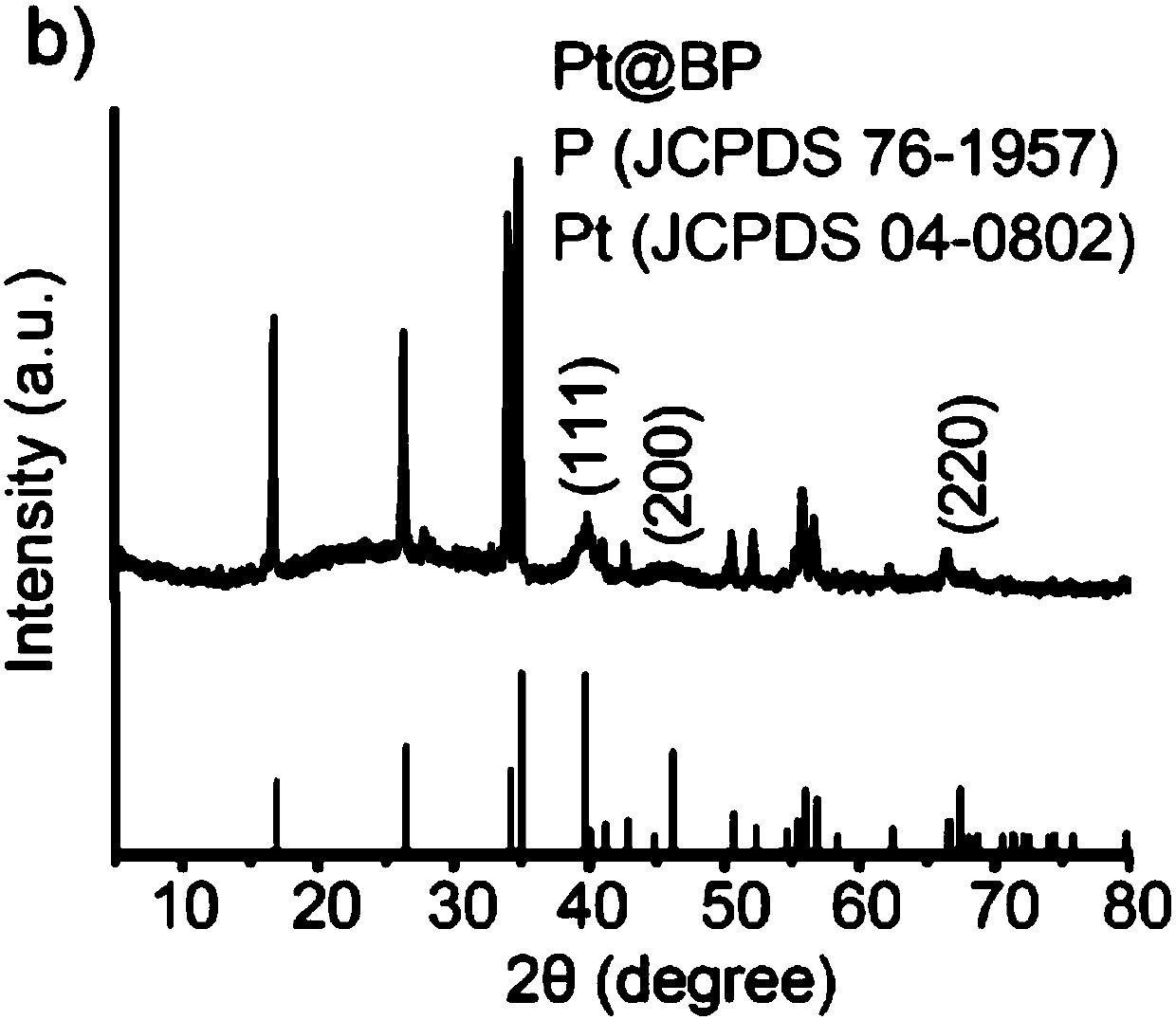

[0063] Preparation of Pt@BP nanocomposites:

[0064] Nanoassembly of Pt@BP nanoparticles was achieved by an ultrasound-assisted one-step synthesis method. The specific method is as follows: first, 0.1 mg of black phosphorus nanosheets are dispersed in 1 ml of deionized water to form a dispersion containing black phosphorus nanosheets, and 100 microliters of chloroplatinic acid with a concentration of 10 mM are added dropwise to the dispersion under the action of ultrasound. Potassium solution, described rate of addition is 50 μ L / min, after dropping, continue reaction 30 minutes under ultrasonic action, the frequency of described ultrasonic is 30KHz, and the power of ultrasonic is 300W; After reaction finishes, high-speed centrifugation (12000rpm, 10min ), to obtain solid particles, wash with deionized water, and dry to obtain BP@Pt composites; in this process, black phosphorus nanosheets are used as supporting substrates and reducing agents.

[0065] Examination of the morph...

Embodiment 2

[0071] Preparation of Pt@BP nanocomposites: Disperse 0.15 mg of black phosphorus nanosheets in 1 ml of deionized water to form a dispersion containing black phosphorus nanosheets, and add 100 μl of 12 mM chlorine Potassium platinum solution, described rate of addition is 60 μ L / min, after dropping, continue to react 30min under ultrasonic action, the frequency of described ultrasonic is 40KHz, and the power of ultrasonic is 300W; After reaction finishes, high-speed centrifugation (12000rpm, 12min), the solid particles were obtained, washed with deionized water, and dried to obtain the BP@Pt composite material

[0072] Examination of the morphology of the nanoassemblies by TEM shows that Pt nanoparticles are evenly distributed on the surface of BP nanosheets. The thickness of the black phosphorus nanosheets is 10nm; the diameter of the black phosphorus nanosheets is 300nm; the average size of the Pt nanoparticles is 5nm.

[0073] The antitumor activity of the Pt@BP composite p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com