Method for preparing corrosion prevention coating with titanium in blast furnace slag

A technology of blast furnace slag and titanium layer, which is applied in the field of anti-corrosion steel, can solve the problems of secondary processing utilization increasing process cost and affecting the quality of titanium deposition layer, so as to achieve the effect of improving quality and avoiding disproportionation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

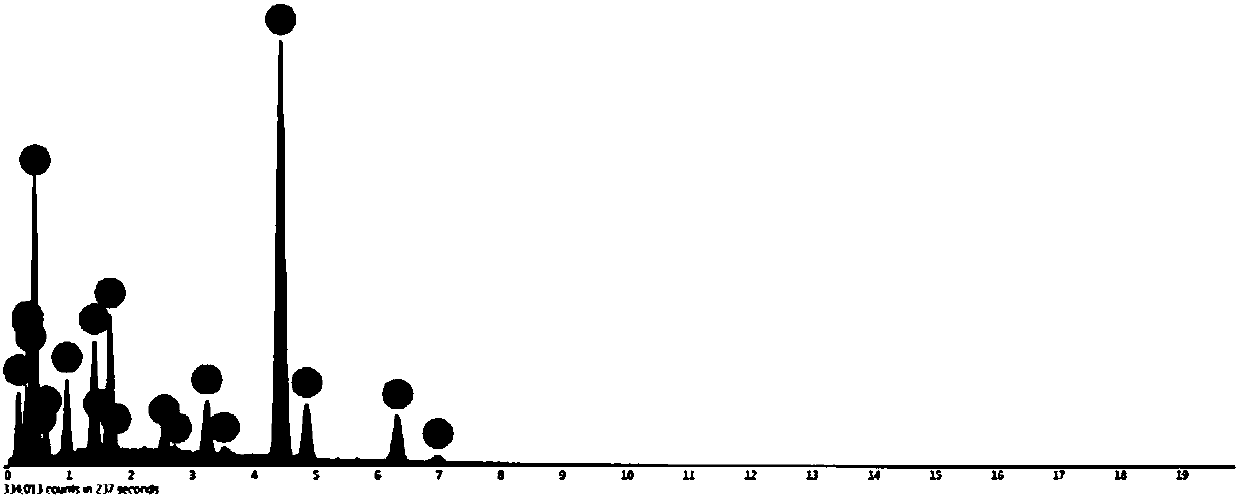

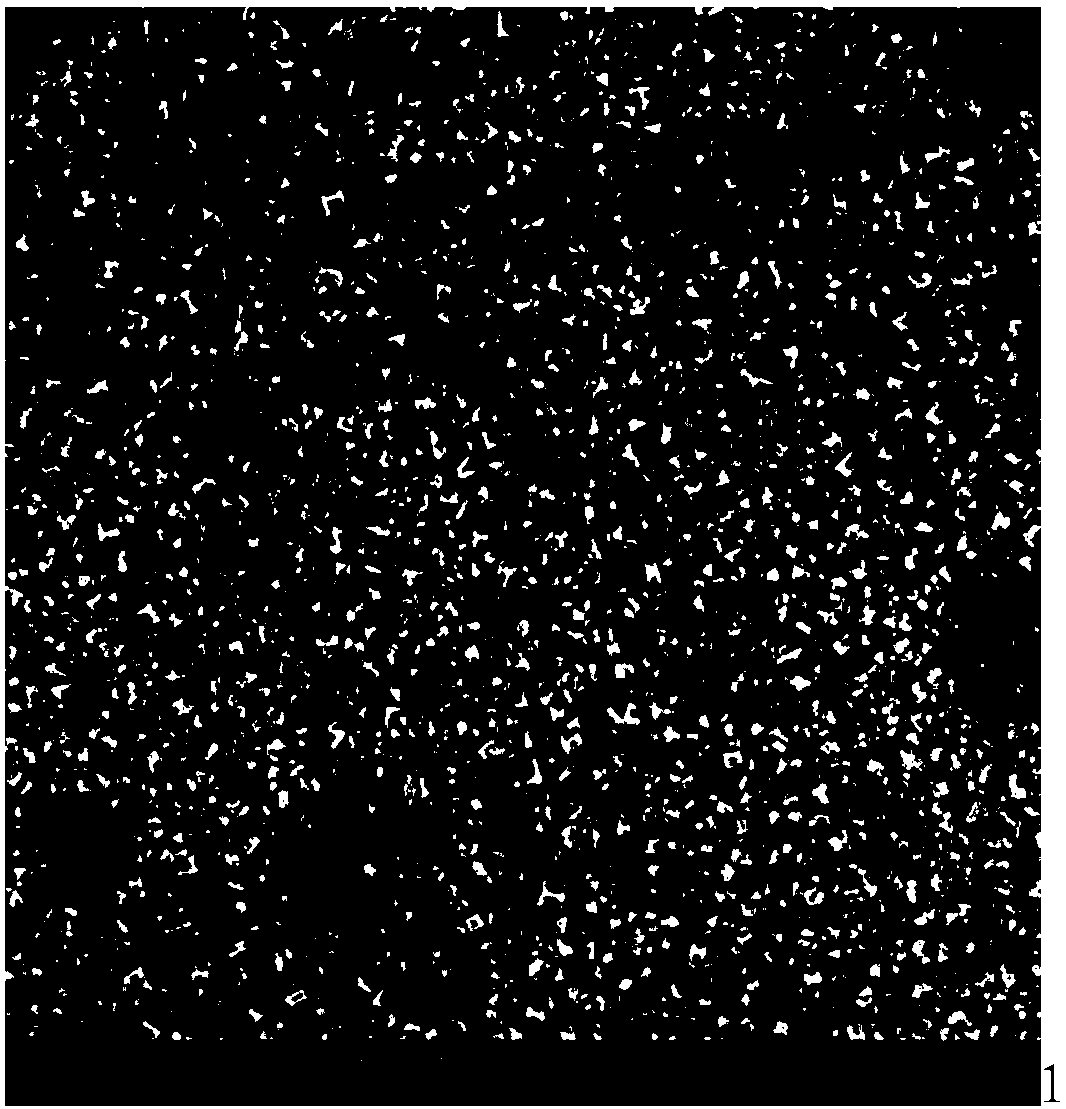

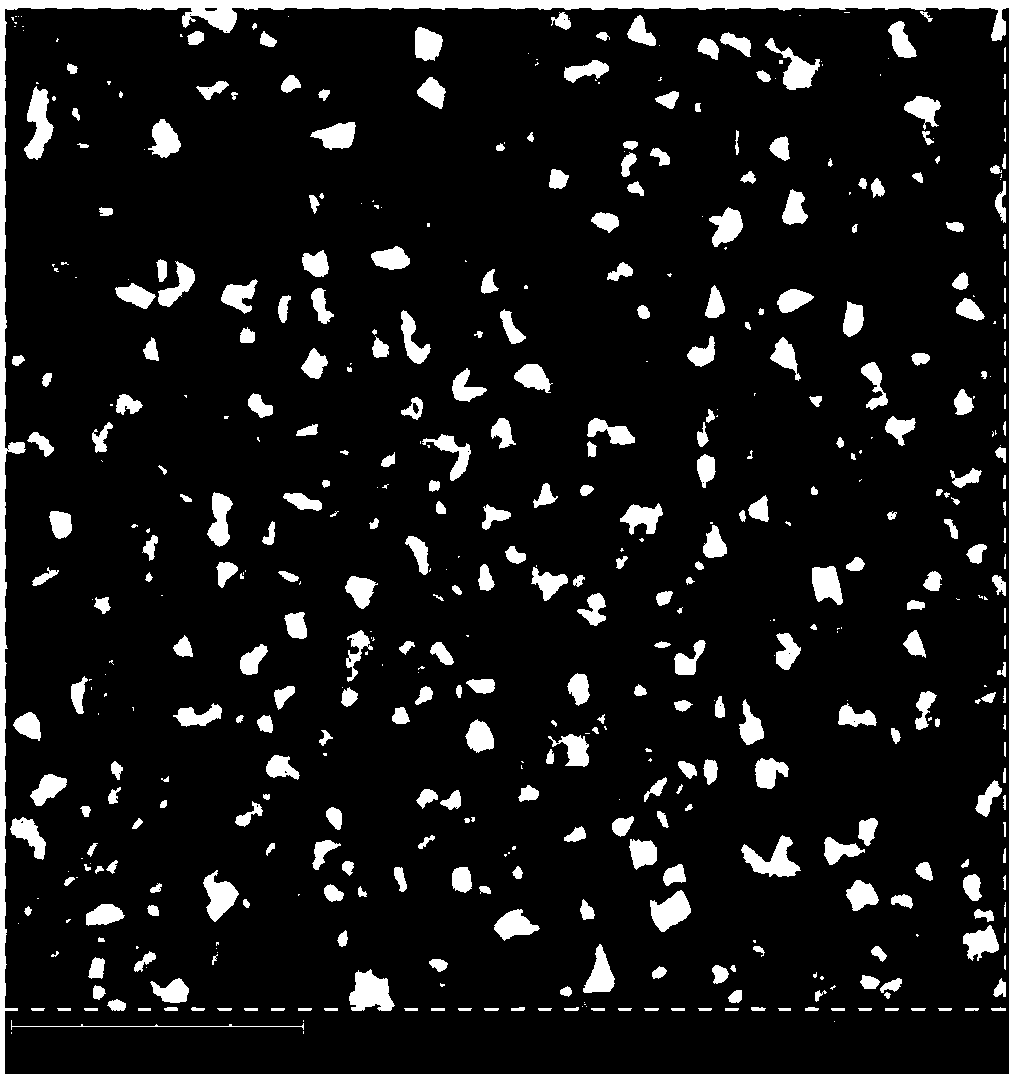

Image

Examples

Embodiment 1

[0028] Analytical pure NaCl, analytical pure KCl, analytical pure NaF, and titanium-containing blast furnace slag with a titanium dioxide content of 20 wt% were ground and refined with an agate mortar, and then dried in a vacuum oven at 473K for 24 hours to remove the reagents. Residual moisture, then sealed and stored for later use;

[0029] Fully mix 78.963g of NaCl, 62.005g of KCl, 89.032g of NaF and 10g of titanium-containing blast furnace slag, pour them into a corundum crucible, and then put it into a resistance for heating. When the temperature displayed on the furnace reaches the set temperature of 730°C ( At this time, the temperature in the furnace is 800°C), and then the molten salt is kept warm for 4 hours, so that the titanium-containing blast furnace slag can reach a state of dissolution equilibrium.

[0030] Polish the carbon steel sheet with metallographic sandpaper (360#, 600#, 800#, 1500#) in order from coarse to fine, and then microwave it in sodium hydroxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com