Method of measuring water phase C4 alcohols in isoprene synthesis industry (olefin aldehyde method)

A technology of isoprene and carbon tetraol, applied in the field of analytical chemistry, can solve problems such as complex composition and achieve accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

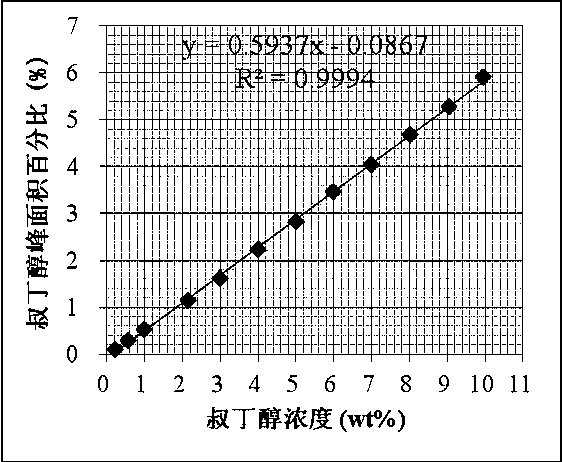

[0022] Since the mass concentration of tert-butanol in the water phase generally does not exceed 10% under actual conditions, a tert-butanol solution with a concentration range of 0-10% was prepared, and the concentration was attached to the concentration by its peak area percentage. figure 1 . Depend on figure 1 It can be seen that the fitting curve is a straight line, and the coefficient of determination R 2 It is 0.9994, and the fitting degree is good.

[0023] Take 192g of 85wt% tert-butanol solution, 30g of 37wt% formaldehyde solution, and 30g of 88wt% phosphoric acid solution, mix the three evenly, and inject the mixed solution into the tubular reactor with a precision metering pump. The reaction temperature is 170°C and the pressure is 1.4MPa. The residence time was 20 minutes, and the obtained product was extracted with n-heptane. The oil phase was located in the upper layer, and the water phase was located in the lower layer. The yield of isoprene was 69%, and 325 g...

Embodiment 2

[0025] Take 180g of 85wt% tert-butanol solution, 41g of 37wt% formaldehyde solution, and 28g of 88wt% phosphoric acid solution, mix the three evenly, and inject the mixed solution into the tubular reactor with a precision metering pump. The reaction temperature is 160°C and the pressure is 1.0MPa. The residence time was 20 minutes, and the obtained product was extracted with n-heptane. The oil phase was located in the upper layer, and the water phase was located in the lower layer. The yield of isoprene was 59%, and 244 g of the aqueous phase containing tert-butanol was obtained. Take 90 g of the aqueous phase, add sodium carbonate solution, adjust the pH to 9, and distill under reduced pressure at a water bath temperature of 55°C to obtain a colorless and clear solution. Analyzed by gas chromatography, it was calculated that the mass of tert-butanol in the water phase was 4.39g, and the concentration was 4.88%.

Embodiment 3

[0027] Take 150g of 85wt% tert-butanol solution, 47g of 37wt% formaldehyde solution, and 23g of 88wt% phosphoric acid solution, mix the three evenly, and inject the mixed solution into the tubular reactor with a precision metering pump. The reaction temperature is 175°C and the pressure is 1.0MPa. The residence time was 30 min, and the obtained product was extracted with n-heptane. The oil phase was located in the upper layer, and the water phase was located in the lower layer. The yield of isoprene was 53%, and 232 g of the aqueous phase containing tert-butanol was obtained. Take 100 g of the aqueous phase, add potassium bicarbonate solution, adjust the pH to 8, and distill under reduced pressure at a water bath temperature of 60°C to obtain a colorless and clear solution. Analyzed by gas chromatography, it was calculated that the mass of tert-butanol in the water phase was 3.68g, and the concentration was 3.68%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com