A kind of beneficiation process of extracting copper and reducing silicon

A silicon reduction and process technology, applied in the field of recycling of non-ferrous metal resources, can solve problems such as high silica content, increased energy consumption of smelting furnaces, and unfavorable economic benefits, so as to improve recovery rate, reduce tailings discharge, and improve economic efficiency. benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

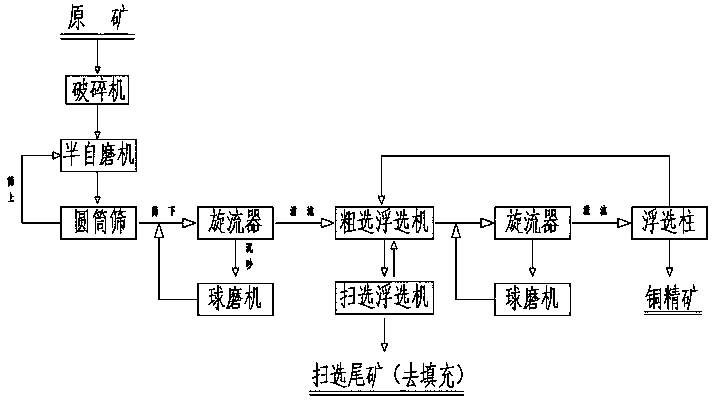

[0017] see figure 1 , a kind of beneficiation process of extracting copper and reducing silicon in this embodiment, raw ore enters semi-autogenous mill and ball mill after coarse crushing, and obtains qualified raw ore pulp, and raw ore pulp is rough-swept through flotation machine to obtain rough separation Concentrate and scavenging tailings, the scavenging tailings are sent to the tailings filling system, the rougher concentrate enters the ball mill for regrinding, and the qualified rougher concentrate slurry is obtained, and the rougher concentrate slurry is then selected through the flotation column. Obtain flotation copper concentrate;

[0018] Specific steps are as follows:

[0019] (1) Raw ore crushing and grinding operation: the raw ore with a particle size of ≤700mm is roughly crushed to below 250mm by a crusher, the copper content in the raw ore is 0.97%, and the silicon content is 37.23%; the raw ore after coarse crushing is sent to the semi-autogenous grinding T...

Embodiment 2

[0025] see figure 1, a kind of beneficiation process of extracting copper and reducing silicon in this embodiment, raw ore enters semi-autogenous mill and ball mill after coarse crushing, and obtains qualified raw ore pulp, and raw ore pulp is rough-swept through flotation machine to obtain rough separation Concentrate and scavenging tailings, the scavenging tailings are sent to the tailings filling system, the rougher concentrate enters the ball mill for regrinding, and the qualified rougher concentrate slurry is obtained, and the rougher concentrate slurry is then selected through the flotation column. Obtain flotation copper concentrate;

[0026] Specific steps are as follows:

[0027] (1) Raw ore crushing and grinding operation: the raw ore with a particle size of ≤700mm is roughly crushed to below 250mm by a crusher, the copper content in the raw ore is 0.91%, and the silicon content is 35.8%; the raw ore after coarse crushing is sent to the semi-autogenous grinding The...

Embodiment 3

[0032] see figure 1 , a kind of beneficiation process of extracting copper and reducing silicon in this embodiment, raw ore enters semi-autogenous mill and ball mill after coarse crushing, and obtains qualified raw ore pulp, and raw ore pulp is rough-swept through flotation machine to obtain rough separation Concentrate and scavenging tailings, the scavenging tailings are sent to the tailings filling system, the rougher concentrate enters the ball mill for regrinding, and the qualified rougher concentrate slurry is obtained, and the rougher concentrate slurry is then selected through the flotation column. Obtain flotation copper concentrate;

[0033] Specific steps are as follows:

[0034] (1) Raw ore crushing and grinding operation: the raw ore with a particle size of ≤700mm is roughly crushed to below 250mm by a crusher, the copper content in the raw ore is 0.99%, and the silicon content is 39.8%; the raw ore after coarse crushing is sent to the semi-autogenous mill Grindi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com