Method for preparing full-fluoride methyl vinyl ether by using fluidized bed

A perfluoromethyl vinyl ether, fluidized bed technology, applied in ether preparation, organic chemistry, ether separation/purification and other directions, can solve problems such as low overall yield, achieve high purity, be conducive to industrial production, save money cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

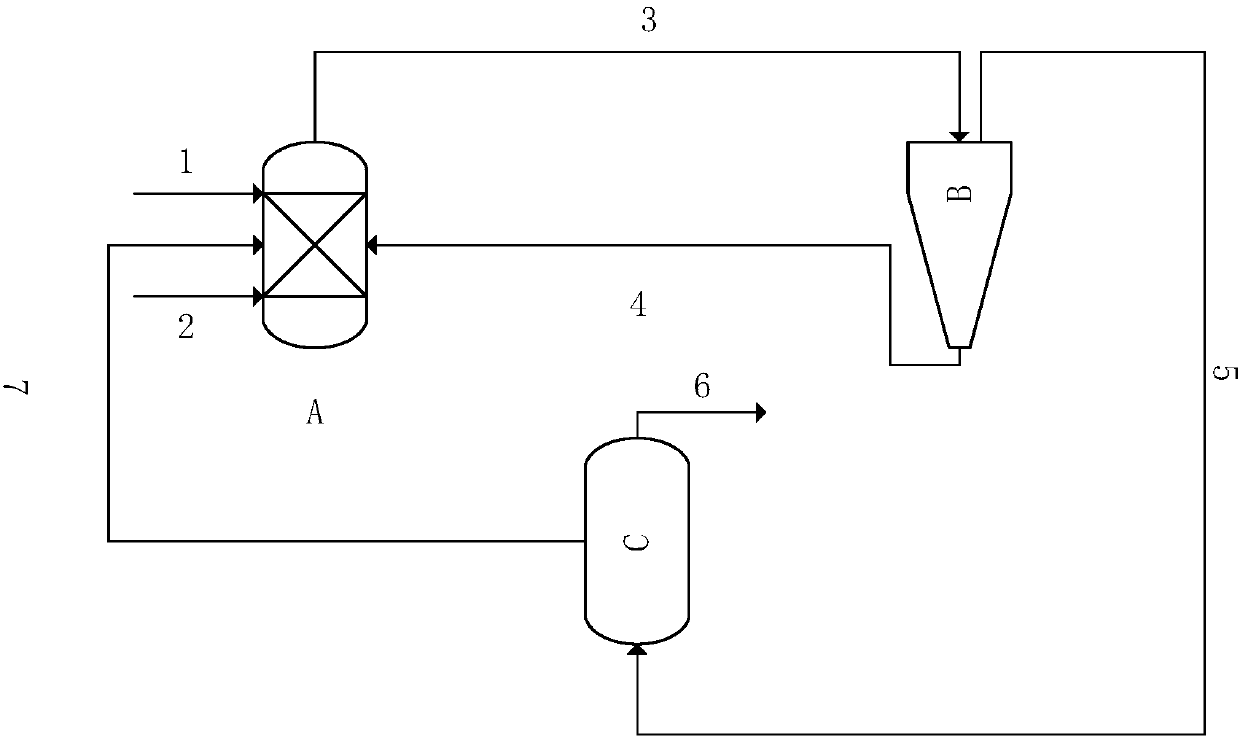

[0038] After passing 6.0Kg of self-made perfluoro 2-methoxypropionyl fluoride (purity ≥ 99%) through a preheater at a temperature of 200 to 230°C, it is divided into three streams, with different flow rates of 0.1m / s and 0.2m / s respectively , 0.5m / s through the fluidized bed corresponding to the design of the three areas. At the same time, 4.0Kg of excess potassium carbonate with an average particle size of 0.1-0.5mm enters the fluidized bed from top to bottom at a flow rate of 0.5m / s, and flows through the distributor with perfluoro 2-methoxypropionyl fluoride. Chemical contact cracking fast reaction, cracking temperature 200 ℃. The fluidized bed selected in this test has a diameter of 1.2m and a bed height of 1.5m. After the reacted mixed product is separated by cyclone separation B, unreacted solid potassium carbonate and stream 5 containing perfluoromethyl vinyl ether are obtained, wherein the unreacted solid potassium carbonate is recycled to the fluidized Bed, continue...

Embodiment 2

[0041]After 3.0Kg of self-made perfluoro 2-methoxypropionyl fluoride (purity ≥ 99%) passed through a preheater at a temperature of 180-230°C, it was divided into three streams, with different flow rates of 0.1m / s and 0.2m / s respectively , 0.3m / s through the fluidized bed corresponding to the design of the three areas. At the same time, 2.1Kg of excess potassium carbonate with an average particle size of 0.1-0.5mm enters the fluidized bed from top to bottom at a flow rate of 0.3m / s, and flows through the distributor with perfluoro 2-methoxypropionyl fluoride. Chemical contact cracking rapid reaction, cracking temperature 190 ℃. The fluidized bed selected in this test has a diameter of 1.5m and a bed height of 1m. After the reacted mixed product is separated by cyclone separator B, unreacted solid potassium carbonate and stream 5 containing perfluoromethyl vinyl ether are obtained, wherein unreacted solid potassium carbonate is circulated to the fluidized bed through the carbon...

Embodiment 3

[0044] After the self-made perfluoro 2-methoxypropionyl fluoride 3.0Kg (purity ≥ 99%) passes through the preheater at a temperature of 180-200°C, it is divided into three streams, respectively with different flow rates of 0.1m / s and 0.2m / s , 0.5m / s through the fluidized bed corresponding to the design of the three regions. At the same time, 2Kg of excess sodium carbonate with an average particle size of 0.1-0.5mm enters the fluidized bed from top to bottom at a flow rate of 0.5m / s, and fluidizes with perfluoro 2-methoxypropionyl fluoride after passing through the distributor. Rapid reaction of contact cracking, cracking temperature 190°C. The fluidized bed selected in this test has a diameter of 1.5m and a bed height of 1m. After the reacted mixed product is separated by cyclone separator B, unreacted solid sodium carbonate and stream 5 containing perfluoromethyl vinyl ether are obtained, wherein unreacted solid sodium carbonate is circulated to the fluidized bed through the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com