Coating material modifier, modified epoxy resin as well as preparation method and application of modified epoxy resin

A technology of epoxy resin and modifier, which is applied in the field of paint modifiers. It can solve the problems of long surface drying and hard drying time, low initial viscosity, and high system viscosity, so as to shorten the surface drying and hard drying time and shorten the construction period. , The effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

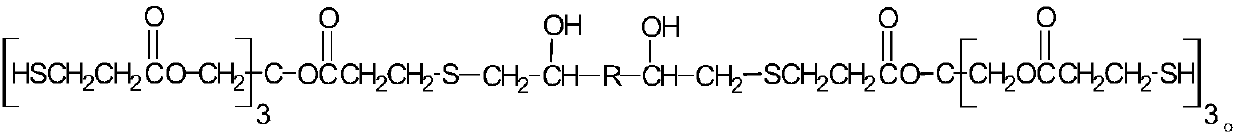

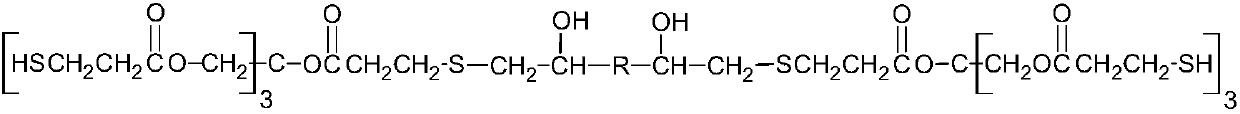

[0080] Polymer HS-Polymer1 of Polythiol Functional Monomer

[0081] Add 100g pentaerythritol mercaptopropionate to the reactor equipped with condenser, thermometer and stirrer, then add 50g xylene, 3g DMP30, heat up to 40°C and stir evenly, then 30gE51 is dissolved in 15g xylene, and Add dropwise to the xylene solution of pentaerythritol mercaptopropionate, stir while adding, keep the reaction temperature at 45°C, react for 2 hours after the dropwise addition is completed until the viscosity of the system no longer increases, raise the temperature to 90°C, remove the xylene solvent in a vacuum, After the removal is completed, it is lowered to room temperature for use. The code is HS-Polymer1, the theoretical active hydrogen equivalent is 208.0g / eq, and the measured viscosity is 6860mPa·s (23°C).

Synthetic example 2

[0083] Polymer HS-Polymer2 of Polythiol Functional Monomer

[0084] Add 100g pentaerythritol mercaptopropionate to the reactor equipped with condenser, thermometer and stirrer, then add 40g xylene, 1g DBU, heat up to 40°C and stir evenly, then 20gF51 is dissolved in 8g xylene, and Add dropwise to the xylene solution of pentaerythritol mercaptopropionate, stir while adding, keep the reaction temperature at 40°C, react for 2 hours after the dropwise addition is completed until the viscosity of the system no longer increases, raise the temperature to 80°C, remove the xylene solvent in vacuum, After the removal is completed, it is lowered to room temperature for use. The code name is HS-Polymer2, the theoretical active hydrogen equivalent is 177.5g / eq, and the measured viscosity is 5178mPa·s (23°C).

Synthetic example 3

[0086] Polymer HS-Polymer3 of Polythiol Functional Monomer

[0087] Add 100g of pentaerythritol mercaptopropionate into the reactor equipped with condenser, thermometer and stirrer, then add 30g of xylene, 1.5g of DBU, heat up to 40°C and stir evenly, then add 20g of hexanediol diglycidyl ether, using Dissolve 6g of xylene, add it dropwise to the xylene solution of pentaerythritol mercaptopropionate, stir while adding, keep the reaction temperature at 35°C, and react for 2h after the addition is completed until the viscosity of the system no longer increases, then raise the temperature to 90°C , the xylene solvent was removed in vacuum, and after the removal was completed, it was cooled to room temperature for use. The code name was HS-Polymer3, the theoretical active hydrogen equivalent: 186.9g / eq, and the measured viscosity was 5385mPa·s (23°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com