Preparation method and use of conjugated microporous polymer with bacteriostatic activity

A technology with conjugated micropores and antibacterial activity, which can be used in botanical equipment and methods, applications, animal repellants, etc., and can solve problems such as operator hazards, limited application scope, and toxicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

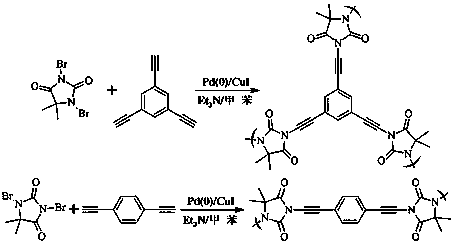

[0011] like figure 1 Shown, the preparation method of the conjugated microporous polymer with bacteriostatic activity of the present invention, its step is: according to 1,3-dibromo-5,5-dimethylhydantoin and 1,3,5 -Triethynylbenzene or 1,4-diethynylbenzene is mixed in a molar ratio of 1 to 10, with toluene and triethylamine as the solvent Pd(0) and CuI as the catalyst, and polymerized at 80°C for 72 hours to obtain a Bacterially active conjugated microporous polymers.

[0012] The use of the above-mentioned conjugated microporous polymer with antibacterial activity is to make a nanoporous foam, or to coat the surface of a porous substrate as an effective antibacterial agent in water.

[0013] The porous substrates mentioned above are filter paper, cloth, sponge.

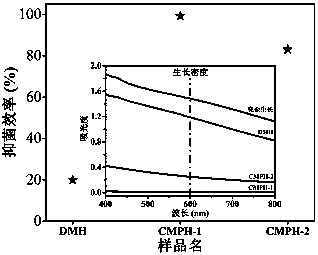

[0014] The purposes of the above-mentioned conjugated microporous polymer with antibacterial activity, the dispersion concentration of the conjugated microporous polymer is 100 μg mL -1 The growth of Escherichia c...

Embodiment 1

[0015] Example 1: Weigh 1,3-dibromo-5,5-dimethylhydantoin (1.8472 g), 1,3,5-triethynylbenzene (0.6007 g), tetrakis(triphenylphosphine ) palladium (0) (100 mg), cuprous iodide (40 mg) in a 50 mL three-neck flask, N 2 Degas for 20 minutes; measure 7.5 mL each of toluene and triethylamine, N 2 Put it into the three-neck bottle under protection, and continue to pass N 2 10 minutes; after the degassing is completed, the temperature of the oil bath is slowly raised to 80 ° C, and the reaction is refluxed for 72 hours in the dark, such as figure 1 shown. After the reaction, the temperature of the reaction system was naturally cooled to room temperature, and the crude product was washed several times with chloroform, acetone, water, and methanol successively until the washing liquid was clear, and the washed product was extracted by Soxhlet with methanol for 72 hours; The product obtained after the extraction was placed in a blast drying oven at 70°C for 24 hours, and was named CMP...

Embodiment 2

[0019] Example 2: Weigh 1,3-dibromo-5,5-dimethylhydantoin (1.8472 g), 1,4-diethynylbenzene (0.7569 g), tetrakis(triphenylphosphine) palladium (0) (100 mg), cuprous iodide (40 mg) in a 50 mL three-necked bottle, N 2 Degas for 20 minutes; measure 7.5 mL each of toluene and triethylamine, N 2 Put it into the three-neck bottle under protection, and continue to pass N 2 10 minutes; after the degassing is completed, the temperature of the oil bath is slowly raised to 80 ° C, and the reaction is refluxed for 72 hours in the dark, such as figure 1 shown. After the reaction, the temperature of the reaction system was naturally cooled to room temperature, and the crude product was washed several times with chloroform, acetone, water, and methanol successively until the washing liquid was clear, and the washed product was extracted by Soxhlet with methanol for 72 hours; The product obtained after the extraction was placed in a blast drying oven at 70°C for 24 hours and named CMPH-2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com