Utilization method of vanadium precipitation wastewater

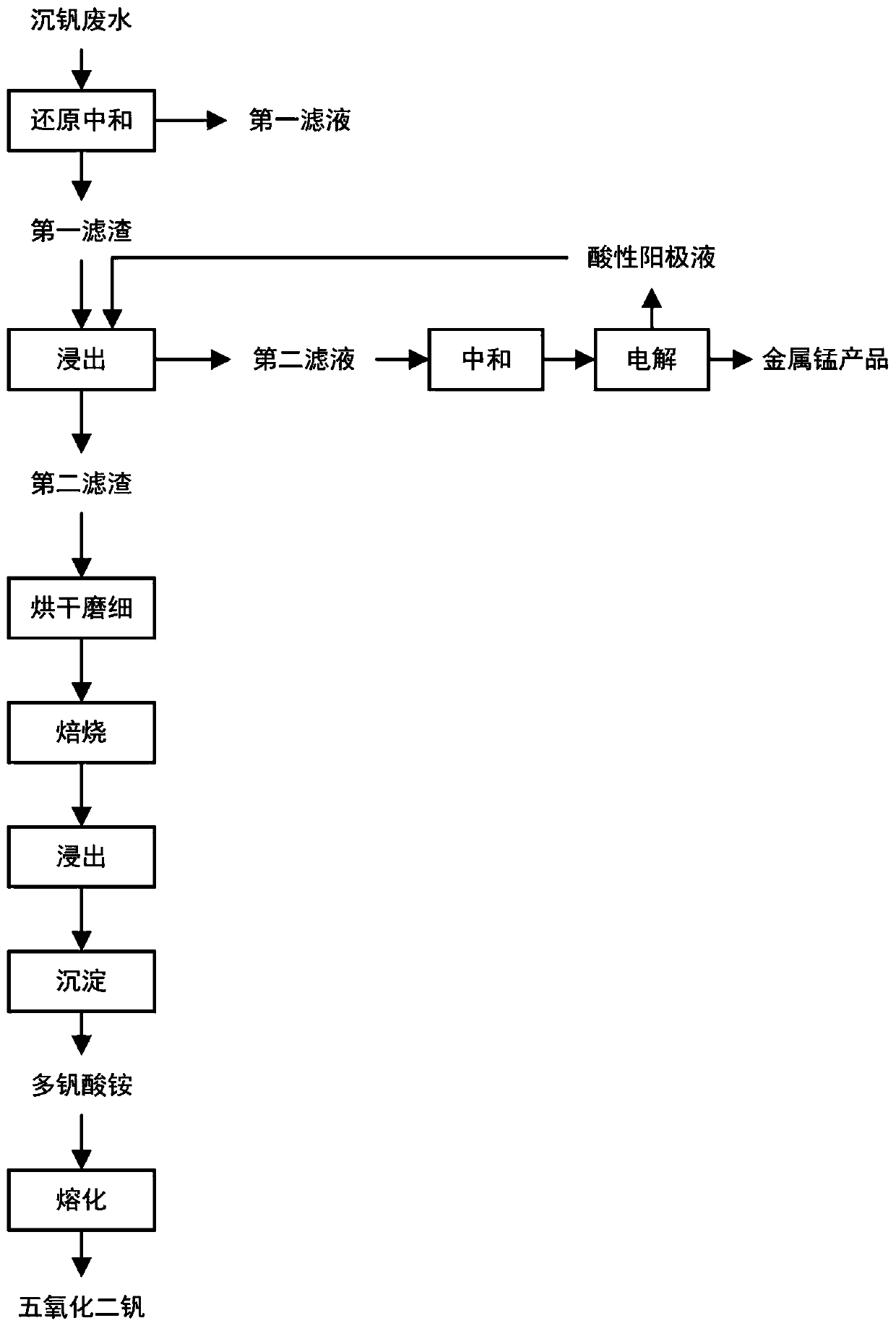

A technology for vanadium precipitation wastewater and vanadium slag is applied in the improvement of process efficiency, instruments, optics and other directions, which can solve the problems of non-vanadium and manganese resource recovery and utilization, achieve significant economic value and realize the effect of rational utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 adopts the inventive method to reclaim vanadium and manganese in the vanadium precipitation wastewater

[0042] Take 10L of vanadium precipitation wastewater (containing 12.2g / L of manganese and 0.15g / L of vanadium), add 35mL of sulfurous acid, stir and react at 40°C for 1.5h, adjust the pH of the solution to 8.0 with 25% ammonia water, and filter to obtain The first filter residue and the first filtrate; add 1.5L acidic anolyte (pH=1.1, containing manganese 5.2g / L) in the filter residue for leaching, adopt sulfuric acid control system pH to be 2.5, carry out solid-liquid separation to obtain the second after the reaction is completed Filter residue and second filtrate (containing manganese 48.7g / L); dry the second filter residue at 80°C, grind it to 120-200 mesh after drying, add 3.0g of CaO and mix it, then roast it at 650°C for 2h, The roasted clinker is obtained, and the clinker is leached with an aqueous solution of pH=3.0, the liquid-solid ratio is 2....

Embodiment 2

[0043] Embodiment 2 adopts the inventive method to reclaim vanadium and manganese in the vanadium precipitation wastewater

[0044]Take 10L of vanadium extraction wastewater (containing 5.4g / L manganese and 0.45g / L vanadium), add 60g of ferrous sulfate, stir and react at 60°C for 1h, adjust the pH of the solution to 8.5 with 25% ammonia water, and filter to obtain The first filter residue and the first filtrate; add 1.0L acidic anolyte (pH=1.2, manganese-containing 6.3g / L) to the filter residue for leaching, adopt sulfuric acid to control the pH of the system to be 3.0, carry out solid-liquid separation after the reaction is completed to obtain the second Filter residue and second filtrate (containing manganese 36.2g / L); dry the second filter residue at 80°C, grind it to 120-200 mesh after drying, add 8.5g of CaO and mix it, then roast it at 880°C for 1h, The roasted clinker is obtained, and the clinker is leached with an aqueous solution of pH=3.0, the liquid-solid ratio is 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com