Foam finishing solution for antistatic PP spun-bonded non-woven fabric and finishing method

A technology for foam finishing and non-woven fabrics, applied in the field of non-woven fabric processing and weaving, can solve the problems of unreported process and finishing effect of anti-static foam finishing of PP spunbond non-woven fabrics, and achieve significant anti-static performance and reduce Cost and water consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: A foam finishing method of antistatic PP spunbonded nonwoven fabric, the finishing steps and process conditions are as follows:

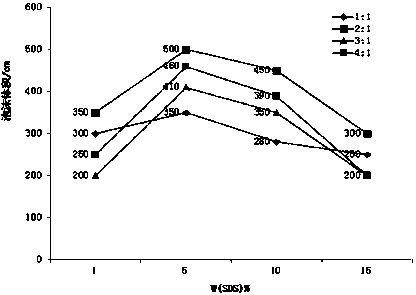

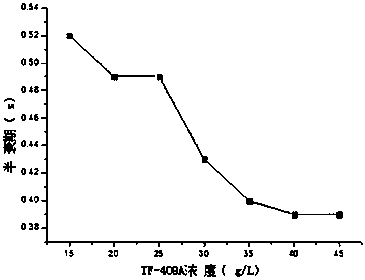

[0032] 1. Take TF-409A antistatic agent (produced by Zhejiang Transfar Co., Ltd.) 20g / L, sodium lauryl sulfate foaming agent 40g / L, carboxymethylcellulose sodium stabilizer 15g / L, and water to prepare Foam Finishing Solution;

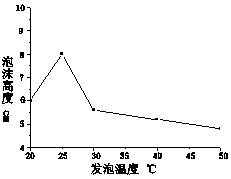

[0033] 2. Stir at 25°C for 5 minutes to obtain a foam finishing solution;

[0034] 3. Set the weight to 40g / m 2 The PP spunbonded nonwoven fabric is foamed on both sides at a bath ratio of 1:40, and the squeeze rate is controlled at 90%;

[0035] 4. Pre-bake the foam-finished fabric at 85°C for 3 minutes and bake at 110°C for 5 minutes to obtain an antistatic PP spunbonded nonwoven fabric.

Embodiment 2

[0036] Embodiment 2: A foam finishing method of antistatic PP spunbonded nonwoven fabric, the finishing steps and process conditions are as follows:

[0037] 1. Take TF-409A antistatic agent 30g / L, sodium lauryl sulfate foaming agent 40g / L, carboxymethyl cellulose sodium stabilizer 15g / L, and water to prepare foam finishing liquid;

[0038] 2. Stir at 25°C for 5 minutes to obtain a foam finishing solution;

[0039] 3. Set the weight to 40g / m 2 The PP spunbonded nonwoven fabric is foamed on both sides at a bath ratio of 1:40, and the squeeze rate is controlled at 90%;

[0040] 4. Pre-bake the foam-finished fabric at 85°C for 3 minutes and bake at 110°C for 4 minutes to obtain an antistatic PP spunbonded nonwoven fabric.

Embodiment 3

[0041] Embodiment 3: A foam finishing solution method for antistatic PP spunbonded nonwovens, the finishing steps and process conditions are as follows:

[0042] 1. Take TF-481 antistatic agent (produced by Zhejiang Chuanhua Co., Ltd.) 30g / L, sodium lauryl sulfate foaming agent 50g / L, sodium alginate stabilizer 15g / L, and water to prepare foam finishing liquid ;

[0043] 2. Stir at 25°C for 5 minutes to obtain a foam finishing solution;

[0044] 3. Set the weight to 50g / m 2 The PP spunbonded nonwoven fabric is foamed on both sides at a bath ratio of 1:50, and the squeeze rate is controlled at 90%;

[0045] 4. Pre-bake the foam-finished fabric at 90°C for 3 minutes and bake at 120°C for 4 minutes to obtain an antistatic PP spunbonded nonwoven fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com