Corn cob fermentation substrate and its preparation method and application

A fermentation substrate and corn cob technology, applied in the field of corn cob fermentation substrate and its preparation, can solve the problems of different initial quality and long time of waste, achieve high comprehensive evaluation index of plant shape indicators, consistent plant growth, and meet the requirements of plant growth required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

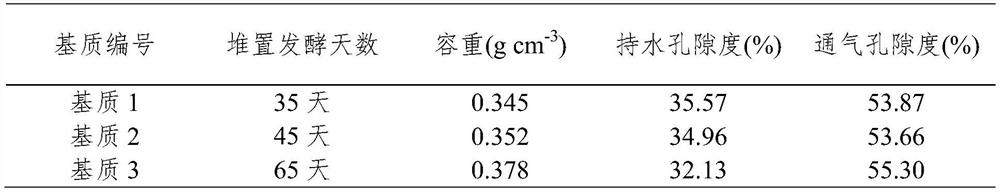

[0035] The preparation of embodiment 1 soilless cultivation substrate

[0036] Fermentation treatment of corncobs: add 0.003kg of bacterial agent per kilogram of corncobs before fermentation. The bacterial agent is purchased from Beijing Jingpuyuan Biological Engineering Co., Ltd., the trade name is organic waste starter, and 0.003kg of gypsum powder is added at the same time, and the C :N ratio to 25:1, the moisture content of the material during fermentation is controlled at 60% (water can be added appropriately), stacked for fermentation, turned over once a week, and the fermentation material is sampled at different fermentation periods, and the fermentation of the sample is terminated. And the sample was dried, and the physical and chemical indicators (Table 1) of the obtained corn cob fermentation substrate were detected for subsequent use.

[0037] Table 1 The physicochemical properties of the obtained corn cob fermentation substrate obtained by different fermentation da...

Embodiment 2

[0043] The application of the substrate of embodiment 2 different stacking time in cucumber cultivation

[0044] The substrate of the formula in Example 1 is used for the cultivation of cucumbers under greenhouse conditions. The greenhouse has fully automatic temperature control and ventilation facilities, which can ensure that a relatively stable and suitable growth environment is provided for the test materials during the test. The results are shown in Table 2.

[0045] The specific method of cucumber soilless cultivation is as follows: When the two leaves of the cucumber are in one center, they are planted in the cultivation medium, and drip irrigation is used, and the irrigation is performed twice a day for 20 minutes each time.

[0046] Table 2 Biomass and yield indicators of cucumbers cultivated in substrates with different stacking times

[0047]

[0048] Note: Each lowercase letter represents the difference level of p<0.05.

[0049] It can be seen from Table 2 tha...

Embodiment 3

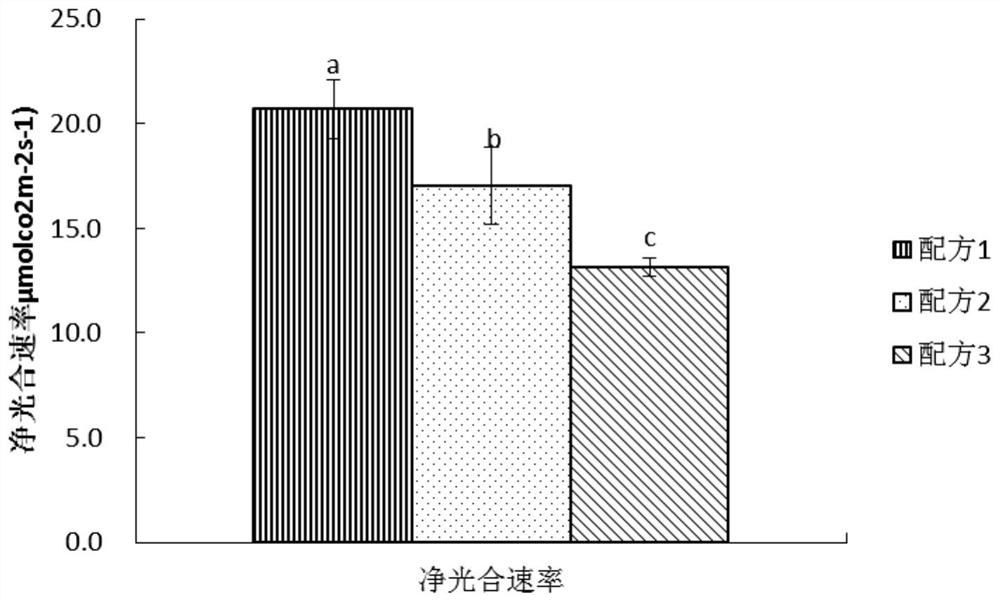

[0050] The influence of the substrate of embodiment 3 different stacking time on the photosynthetic rate of cucumber

[0051] The matrix of the formula in Example 1 is used for the cultivation of cucumbers under greenhouse conditions. The greenhouse has fully automatic temperature control and ventilation facilities, which can ensure that a relatively stable and suitable growth environment is provided for the test materials during the test.

[0052] The photosynthetic rate of cucumber plant leaves was measured by using a photosynthetic instrument Li6400 during the cucumber growth period, and the results are as follows: figure 1 shown by figure 1It can be seen that the net photosynthetic rate of cucumbers grown on the substrate stacked for 35 days was significantly higher than that of the substrates stacked for 45 days and 65 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com