A preparation method of flux for solder paste and its ultrasonic rapid cooling system

A technology of flux and solder paste is applied in the field of preparation of flux for solder paste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

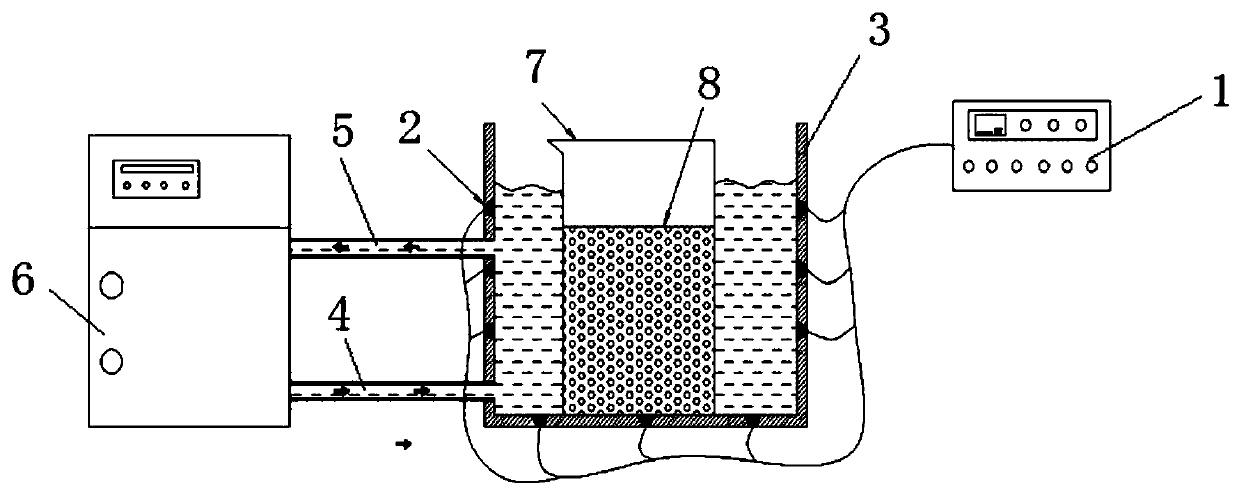

Image

Examples

Embodiment 1

[0015] The preparation method of SnAgCu series flux for solder paste, the method steps are as follows:

[0016] (1) Place the modified rosin in the SnAgCu series flux in the emulsification equipment to heat and melt, the heating temperature is 140℃~145℃; among them, the modified rosin is the compound of KE-604 rosin and KR-610 rosin, the ratio It is 3:2.

[0017] (2) Slowly add the prepared solvents diethylene glycol dimethyl ether and diethylene glycol octyl ether into the emulsification equipment of melted modified rosin in proportion, keep the temperature at 135 ° C ~ 140 ° C, emulsify at high speed for 30 minutes, and emulsify The speed is 3000rpm and the weight ratio of the two ethers is 1:3.

[0018] (3) Add the active agent tetracosacic acid and succinic acid mixture, the thixotropic agent ricinoleoyl diethanolamine and lauryl hydroxystearic acid mixture amide in the emulsification equipment in proportion, keep the temperature at 125 ° C ~ 130 ° C, High-speed emulsifi...

Embodiment 2

[0021] The preparation method of SnPb series flux for solder paste, the method steps are as follows:

[0022] (1) Place the modified rosin in the SnPb series flux in the emulsification equipment to heat and melt. The heating temperature is 145°C-150°C. Among them, the modified rosin is a compound of KE-604 and water-white rosin, and the ratio is 1. :1.

[0023] (2) Slowly add the prepared solvents diethylene glycol dimethyl ether and diethylene glycol octyl ether into the emulsification equipment of melted modified rosin in proportion, keep the temperature at 130 ° C ~ 135 ° C, emulsify at high speed for 30 minutes, and emulsify The speed is 4000rpm, the weight ratio of the two ethers is 1:1

[0024] (3) Add the mixture of active agent lignoceric acid and adipic acid, the mixture of thixotropic agent ricinoleoyl diethanolamine and lauryl hydroxystearic acid amide into the emulsification equipment in proportion, keep the temperature at 120℃~125℃, Emulsify for 20 minutes, and ...

Embodiment 3

[0027] The preparation method of SnBi-X series flux for solder paste, the method steps are as follows:

[0028] (1) Prepare the modified rosin in the SnBi-X series flux according to the proportion, weigh it, place it in the emulsification equipment to heat and melt it, and the heating temperature is 140℃~150℃. Among them, the modified rosin is a compound of KE-604 rosin and water white rosin, the ratio is 1:2.

[0029] (2) Slowly add the prepared solvents diethylene glycol dimethyl ether and diethylene glycol octyl ether into the melted modified rosin in proportion, place in the emulsification equipment, keep the temperature at 130°C to 140°C, and emulsify at a high speed for 30 minutes, the emulsification speed is 3500rpm; the weight ratio of the two ethers is 3:2

[0030] (3) Add the mixture of active agent lignoceric acid and stearic acid, the mixture of thixotropic agent ricinoleoyldiethanolamine and lauryl hydroxystearic acid amide in the emulsification equipment, keep t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com