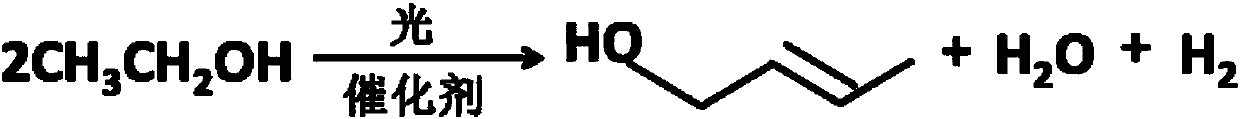

Method for synthesizing crotyl alcohol by converting ethanol through photocatalysis

A technology of crotyl alcohol and photocatalysis, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of hydroxyl compounds, etc., can solve the problems of undiscovered photocatalytic ethanol, etc., achieve environmental friendliness, mild reaction conditions, and simple synthesis process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

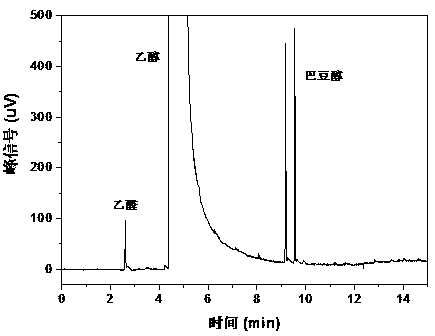

Image

Examples

Embodiment 1

[0033] 10mmol Cd(NO 3 ) 2 4H 2 O and 30mmol thiourea (CN 2 h 4 S) respectively dissolved in 60mL of ethylenediamine, fully dissolved and mixed evenly, then placed in a 100mL high-pressure homogeneous reactor, heated at a rate of 5°C / min, and kept at 160°C for 48h. Centrifuge and wash to neutral, and place overnight in a vacuum oven at 60°C. One-dimensional CdS solid powder can be obtained after drying and grinding. Then add the prepared 0.2g CdS powder into 30mL dissolved with 0.025g Ni(NO 3 ) 2 ·6H 2 O, 0.025g sodium molybdate (NaMo 2 o 4 2H 2 O) and 0.06g of cysteine (L-cysteine) in the aqueous solution, fully dispersed, placed in a 60ml high-pressure homogeneous reactor, heated at a rate of 5°C / min, and kept at 200°C for 24h. Centrifuge and wash several times, and place in a vacuum oven at 60°C overnight to obtain a 12wt%-NiMoS@CdS photocatalyst. Take 5mg of the prepared 12wt%-NiMoS@CdS photocatalyst and add it to 20mL of 1M NaOH ethanol solution, pass inert g...

Embodiment 2

[0035] 10mmol Cd(NO 3 ) 2 4H 2 O and 30mmol thiourea (CN 2 h 4S) respectively dissolved in 60mL of ethylenediamine, fully dissolved and mixed evenly, then placed in a 100mL high-pressure homogeneous reactor, heated at a rate of 5°C / min, and kept at 160°C for 48h. Centrifuge and wash to neutral, and place overnight in a vacuum oven at 60°C. One-dimensional CdS solid powder can be obtained after drying and grinding. Add the prepared 0.2g CdS powder to 30mL and dissolve 0.02g sodium molybdate (Na 2 MO 6 ) and 0.05g of cysteine (L-cysteine) in an aqueous solution, fully dispersed, placed in a 60ml high-pressure homogeneous reactor, heated at a rate of 5°C / min, and kept at 200°C for 12h. Centrifuged and washed several times, placed in a vacuum oven at 60°C overnight to obtain 12wt%-MoS 2 / CdS photocatalyst. Take 2mg of the prepared 12wt%-MoS 2 The @CdS photocatalyst was added to 50mL of 1M KOH ethanol solution, and the inert gas argon was introduced under stirring to fu...

Embodiment 3

[0037] 10mmol Cd(NO 3 ) 2 4H 2 O and 30mmol thiourea (CN 2 h 4 S) respectively dissolved in 60mL of ethylenediamine, fully dissolved and mixed evenly, then placed in a 100mL high-pressure homogeneous reactor, heated at a rate of 5°C / min, and kept at 160°C for 48h. Centrifuge and wash to neutral, and place overnight in a vacuum oven at 60°C. One-dimensional CdS solid powder can be obtained after drying and grinding. Then add 0.2g of the prepared CdS powder into 50mL lactic acid aqueous solution (30wt%), after fully dispersed, add chloroplatinic acid solution according to the loading capacity of 1wt%, stir and blow nitrogen. Reduction with a 200W xenon lamp for 3h yielded CdS loaded with Pt nanoparticles. Centrifuge and wash several times, and place overnight in a vacuum oven at 60°C for later use. Take 5mg of the prepared 1wt%-Pt@CdS photocatalyst and add it to 20mL 0.01M NaOH ethanol solution. After stirring, pass inert gas argon to fully replace the oxygen in the syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com