High-temperature-resistant compound leveling agent and preparation method thereof

A technology of leveling agent and composite flow, applied in the direction of coating, can solve the problems of increasing environmental pollution, unspecified resistance performance, etc., and achieve the effects of long operating time, good leveling and antifouling properties, and good environmental performance.

Inactive Publication Date: 2018-03-23

KUSN ACHILLES ARTIFICIAL LEATHER

View PDF8 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] Chinese patent CN102153902A discloses a fluorocarbon anti-shrinkage crater leveling agent for coating ink, which is prepared by mixing, heating and stirring a solvent, a fluorine-containing acrylate monomer and an initiator, and the prepared leveling agent has a surface tension of 21-24 and has a certain The anti-shrinkage ability, but it does not explain the resistance of the structure product to other factors such as high temperature. At the same time, solvents are needed in the preparation process, which increases environmental pollution and the degree of harm to the human body when the product is used.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

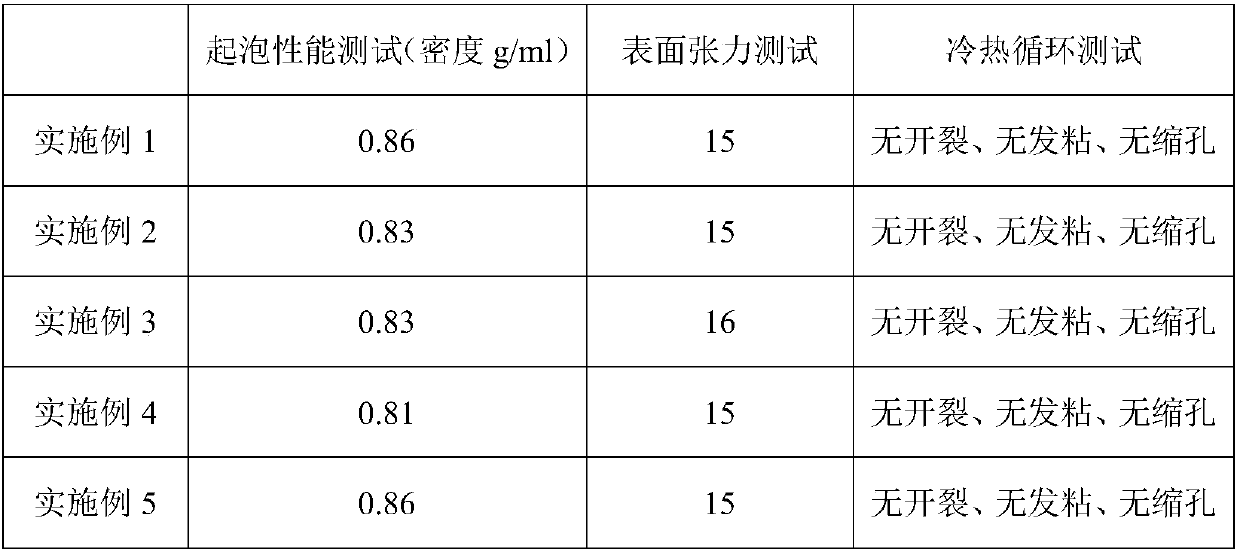

Embodiment 1-9

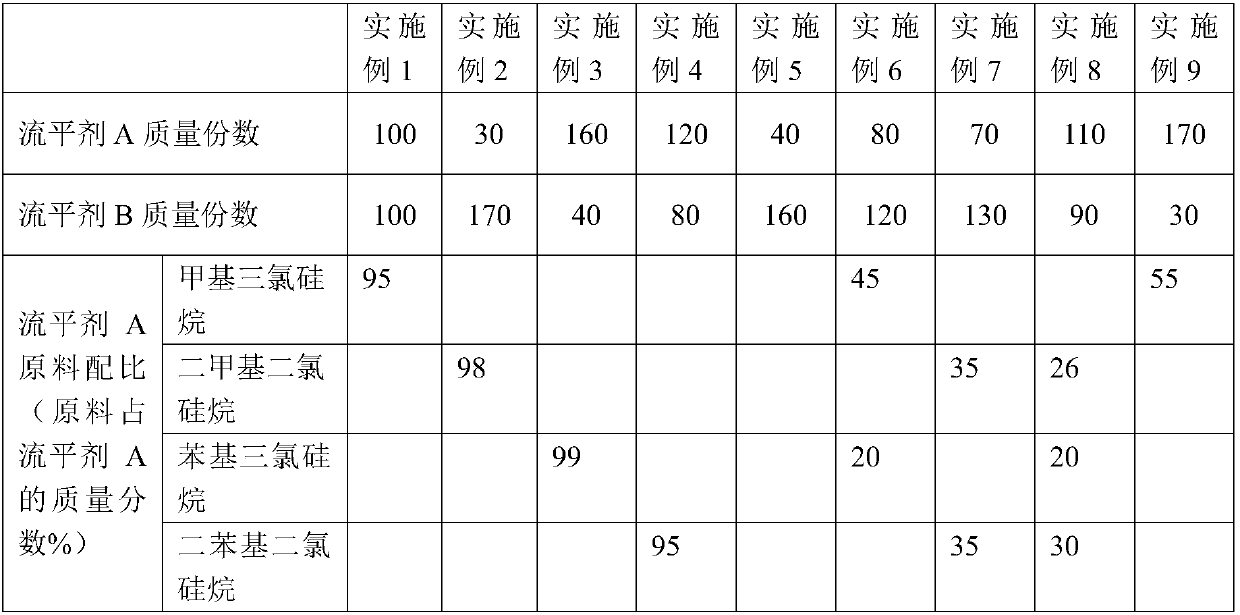

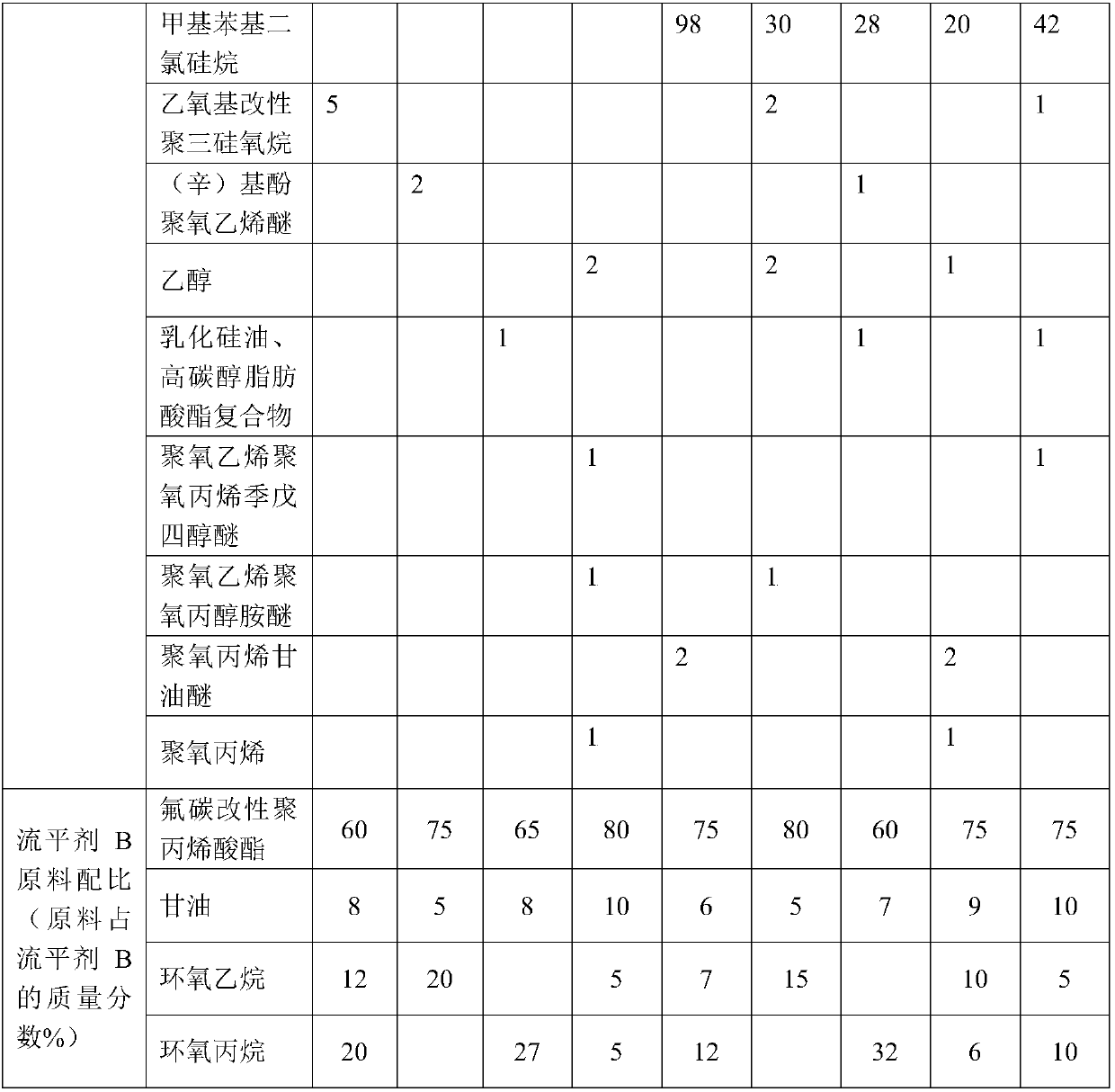

[0024] The raw material of compound leveling agent is prepared in embodiment 1-9 as shown in table 1

[0025] Table 1: Raw materials for making composite leveling agent

[0026]

[0027]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The invention relates to the technical field of coatings, and discloses a high-temperature-resistant compound leveling agent which comprises, by weight, 1-100 parts of leveling agent A and 1-100 partsof leveling agent B. The leveling agent A comprises organic silicon resin and additives, and the leveling agent B comprises fluorocarbon modified polyacrylic ester, glycerin, ethylene oxide and / or propylene oxide. The invention further discloses a preparation method of the high-temperature-resistant compound leveling agent. The preparation method includes the steps: preparing the leveling agent Aand the leveling agent B; mixing the leveling agent A and the leveling agent B; stirring mixture for 4-20 hours at the normal temperature, and sufficiently and uniformly mixing the mixture to obtainthe compound leveling agent. On one hand, the prepared compound leveling agent has surface tension reducing ability, on the other hand, integrated side chain methyl is kept, excellent smoothness is given, preparation processes are good in adaptation, production efficiency is high, products do not contain poisonous catalysts such as lead and mercury and has good leveling properties and antifoulingproperties, and environmental protection performance is good.

Description

technical field [0001] The invention relates to the technical field of coatings, in particular to a high-temperature-resistant composite leveling agent and a preparation method thereof. Background technique [0002] Leveling agent is a commonly used coating additive, which can promote the formation of a flat, smooth and uniform coating film during the drying and film forming process of the coating. A class of substances that can effectively reduce the surface tension of coating fluids and improve their leveling and uniformity. It can improve the permeability of the coating solution, reduce the possibility of spots and marks when brushing, increase the coverage, and make the film formation uniform and natural. Mainly surfactants, organic solvents, etc. There are many types of leveling agents, and the types of leveling agents used in different coatings are also different. High boiling point solvents or butyl cellulose can be used in solvent-based finishes. In water-based f...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Applications(China)

IPC IPC(8): C09D7/47

Inventor 赵建明陈清谭国庆施敏

Owner KUSN ACHILLES ARTIFICIAL LEATHER

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap