Novel green and environment-friendly adhesive of lithium ion battery

A technology of lithium-ion batteries and binders, which is applied in the manufacture of battery electrodes, secondary batteries, and electrolyte batteries, etc. It can solve the problems of different components, reduce the compatibility of electrode materials and SEI films, achieve high cost performance, and improve cycle stability. The effect of the property and the simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

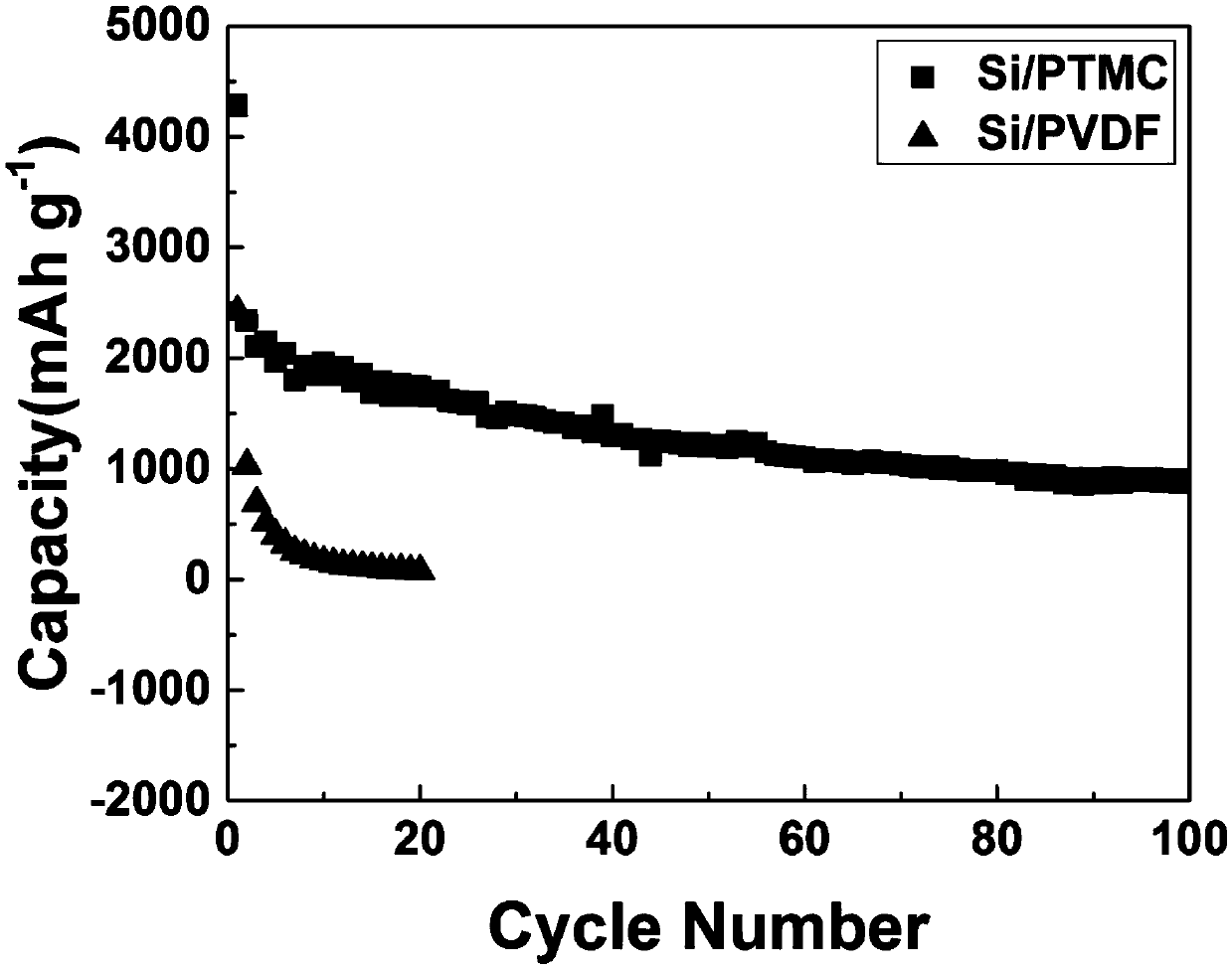

Embodiment 1

[0028] Measure 1.83g of NMP into the weighing bottle, weigh 0.0366g of polytrimethylene carbonate into the weighing bottle, stir to dissolve. Weigh 0.061 g of silicon nanoparticles and 0.0244 g of acetylene black, grind them evenly, add them into a weighing bottle, stir for 24 hours, and disperse evenly. Press the Cu foil into a disc with a diameter of 1.4 cm, weigh it, and record it as weight 1. Spread the adjusted slurry evenly on the treated Cu foil, dry it in vacuum at 80°C for 12h, weigh it, and record it as weight 2. Subtract weight 1 from weight 2 to obtain the weight of the coating, recorded as weight 3. Move the dried pole piece into the glove box, and assemble the 2016 button cell with the lithium piece as the counter electrode. Use 1M (mol / L) (the volume ratio of conductive salt is 1:1) EC / DEC mixed solution as the electrolyte. Seal the assembled battery and let it stand for 10 hours. Test the electrochemical performance of the static battery on a charge-dischar...

Embodiment 2

[0030] Measure 2.44g of NMP into the weighing bottle, weigh 0.0488g of polytrimethylene carbonate into the weighing bottle, and stir to dissolve. Weigh 0.061 g of silicon nanoparticles and 0.0122 g of acetylene black, grind them evenly, add them into a weighing bottle, stir for 24 hours, and disperse evenly. Press the Cu foil into a disc with a diameter of 1.4 cm, weigh it, and record it as weight 1. Spread the adjusted slurry evenly on the treated Cu foil, dry it in vacuum at 80°C for 12h, weigh it, and record it as weight 2. Subtract weight 1 from weight 2 to obtain the weight of the coating, recorded as weight 3. Move the dried pole piece into the glove box, and assemble the 2016 button cell with the lithium piece as the counter electrode. Use 1M (the volume ratio of conductive salt is 1:1) EC / DEC mixed solution as the electrolyte. Seal the assembled battery and let it stand for 10 hours. Test the electrochemical performance of the static battery on a charge-discharge t...

Embodiment 3

[0032] Measure 1.22g of NMP into the weighing bottle, weigh 0.0244g of polytrimethylene carbonate into the weighing bottle, stir to dissolve. Weigh 0.061 g of silicon nanoparticles and 0.0366 g of acetylene black, grind them evenly, add them into a weighing bottle, stir for 24 hours, and disperse evenly. Press the Cu foil into a disc with a diameter of 1.4 cm, weigh it, and record it as weight 1. Spread the adjusted slurry evenly on the treated Cu foil, dry it in vacuum at 80°C for 12h, weigh it, and record it as weight 2. Subtract weight 1 from weight 2 to obtain the weight of the coating, recorded as weight 3. Move the dried pole piece into the glove box, and assemble the 2016 button cell with the lithium piece as the counter electrode. Use 1M (the volume ratio of conductive salt is 1:1) EC / DEC mixed solution as the electrolyte. Seal the assembled battery and let it stand for 10 hours. Test the electrochemical performance of the static battery on a charge-discharge teste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com