Titanium dioxide catalytic ozonation catalyst as well preparation and denitration application

A technology of titanium dioxide and black titanium dioxide, which is applied in the direction of titanium oxide/hydroxide, titanium dioxide, physical/chemical process catalysts, etc., can solve the problems of increasing operating costs and depleting ozone, and achieves the effect of cheap preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further elaborated below in conjunction with examples.

[0032] First, 28 ml of butyl phthalate and 2 g of urea were dissolved in 80 ml of absolute ethanol, and the resulting mixture was stirred at room temperature for 30 minutes to obtain solution A. Secondly, 2ml of hydrochloric acid and 10ml of water were dissolved in 20ml of absolute ethanol to obtain solution B. Then, the solution B was added to the solution A, and the mixture was continuously stirred until it became a white sol, and then heated in a water bath at 35°C for 30 minutes, and the resulting mixture was allowed to stand for 24 hours. The obtained sol was dried at 120° C., and finally calcined at 500° C. for 3 hours with a heating rate of 4° C. / min to obtain black titanium dioxide.

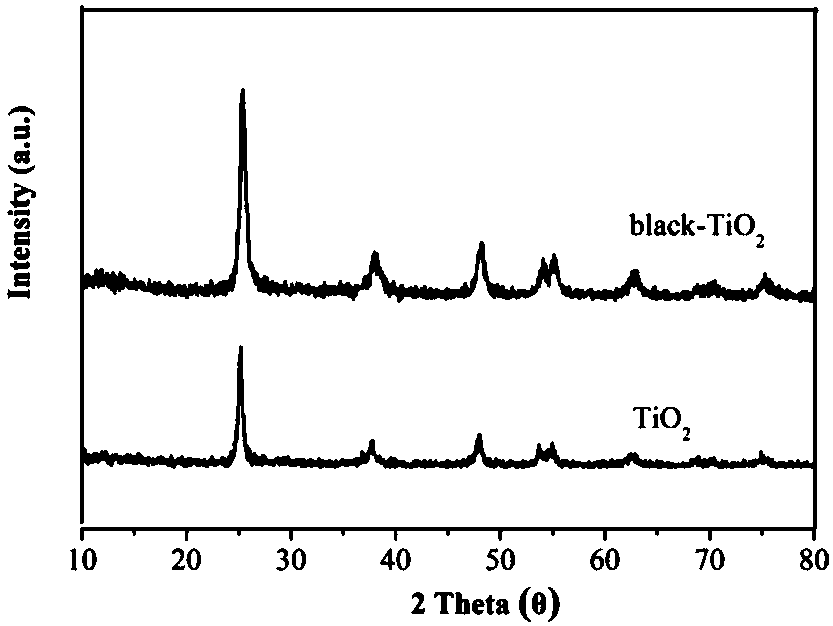

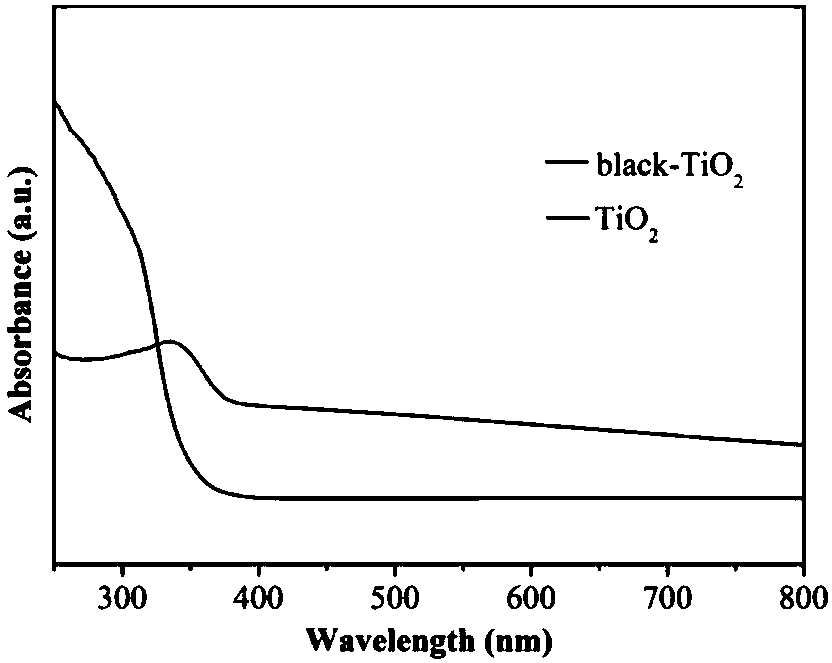

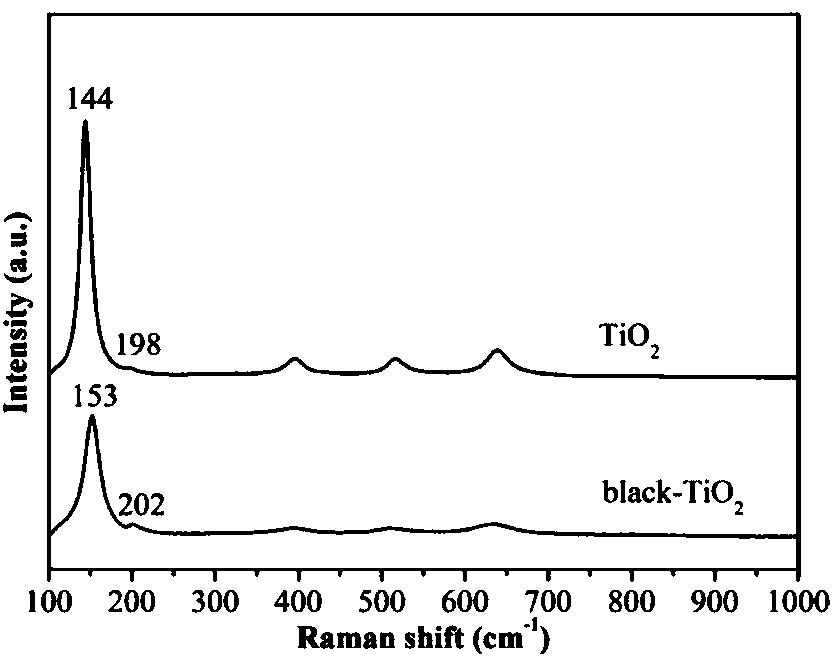

[0033] figure 1 The XRD pattern of the catalyst shows that the black titanium dioxide is anatase component. figure 2 , 3 , 4 are the solid UV, Raman and NH of the catalyst respectively 3 -TPD charac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com