fe 2 o 3 /g-c 3 no 4 Composite system, preparation method and application

A technology of g-c3n4 and fe2o3 is applied in the field of photocatalyst synthesis to achieve the effects of short reaction time, excellent photocatalytic activity and convenient mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

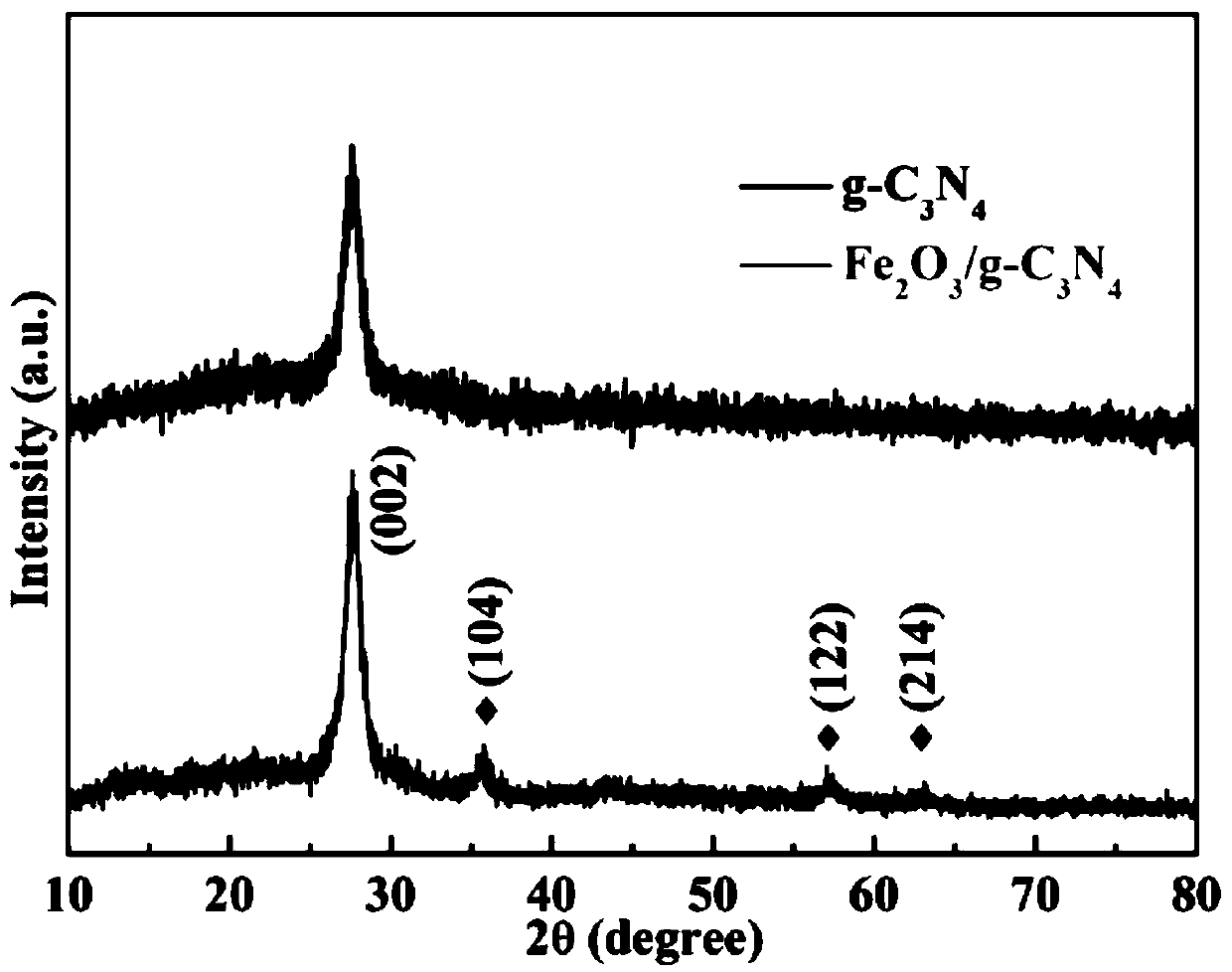

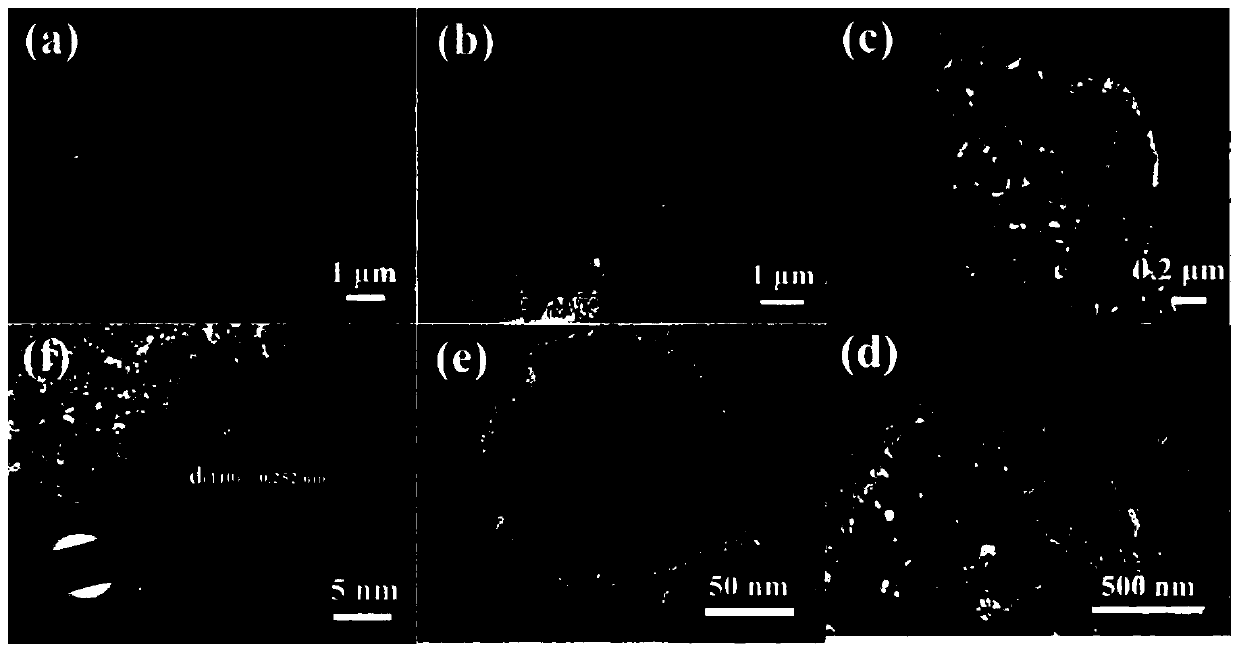

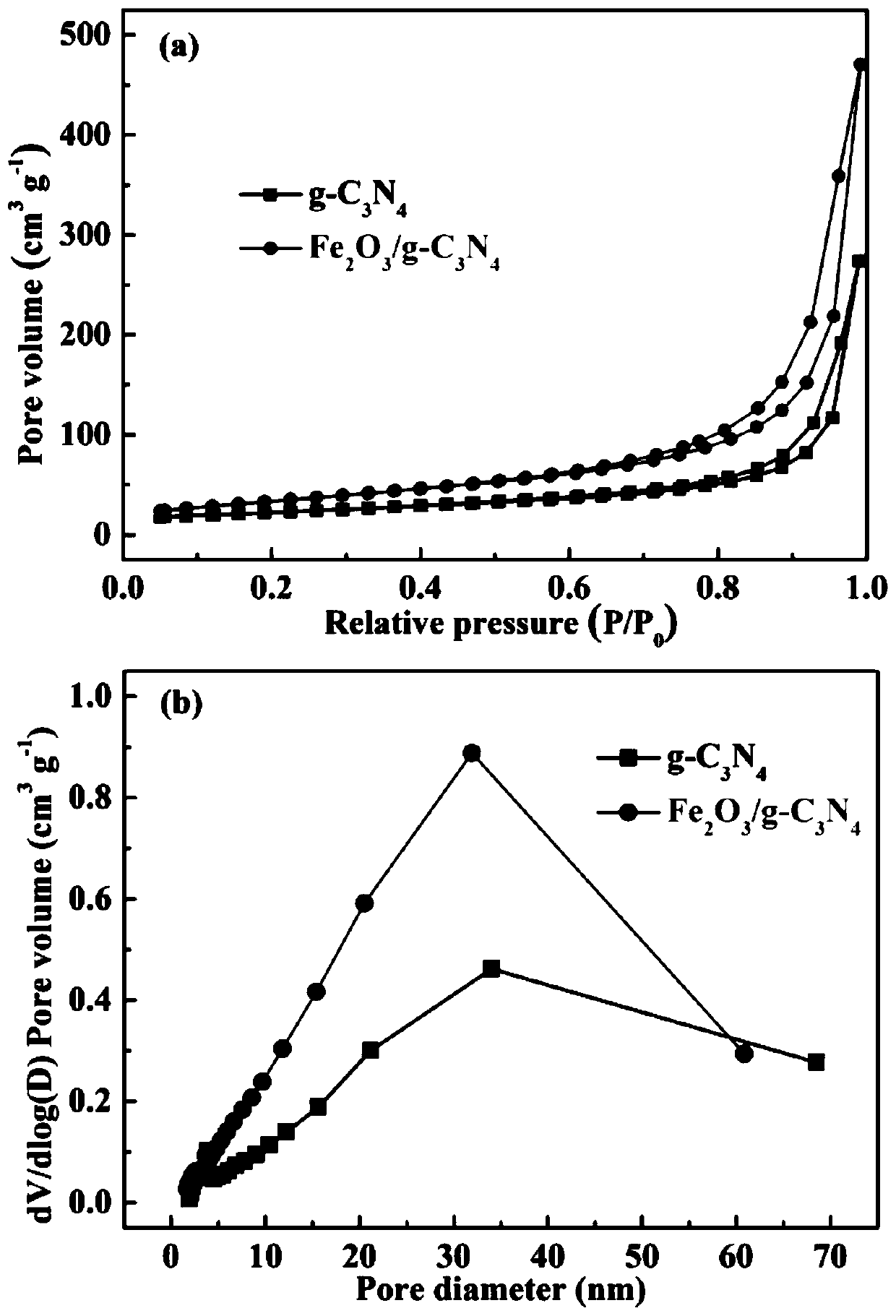

[0035] Example 1: Mesoporous "Z-Scheme" type Fe 2 o 3 / g -C 3 N 4 Preparation of composite system

[0036] 1. Preparation of g-C 3 N 4 catalyst of light

[0037] 1. Weigh urea, dry it in an oven at 80°C for 24 hours, grind it and put it into a crucible, cover it, and place it in a muffle furnace at 2°C min -1 The heating rate is from room temperature to 550°C, and calcined for 4h.

[0038] 2. Use 1mol L after taking it out -1 Soak and stir in nitric acid for 24 hours, filter, wash with distilled water 7-8 times until neutral, and dry in an oven at 80°C for 24 hours.

[0039] 3. Take out the sample and grind it, place it in a crucible, and calcinate it in a muffle furnace at 500°C for 4 hours without a cover to obtain mesoporous g-C 3 N 4 catalyst of light.

[0040] 2. Preparation of mesoporous “Z-Scheme” Fe 2 o 3 / g -C 3 N 4 Composite system

[0041] 1. Accurately weigh 0.2g of P123 and 0.1g of hexamethyleneimine, dissolve in a mixed solution of 16.5ml of absol...

Embodiment 2

[0048] Example 2: Mesoporous "Z-Scheme" type Fe 2 o 3 / g -C 3 N 4 Preparation of composite system

[0049] 1. Preparation of g-C 3 N 4 catalyst of light

[0050] 1. Weigh urea, dry it in an oven at 80°C for 24 hours, grind it and put it into a crucible, cover it, and place it in a muffle furnace at 2°C min -1 The heating rate is from room temperature to 550°C, and calcined for 4h.

[0051] 2. Use 1mol L after taking it out -1 Soak and stir in nitric acid for 24 hours, filter, wash with distilled water 7-8 times until neutral, and dry in an oven at 80°C for 24 hours.

[0052] 3. Take out the sample and grind it, place it in a crucible, and calcinate it in a muffle furnace at 500°C for 4 hours without a cover to obtain mesoporous g-C 3 N 4 catalyst of light.

[0053] 2. Preparation of mesoporous “Z-Scheme” Fe 2 o 3 / g -C 3 N 4 Composite system

[0054] 1. Accurately weigh 0.2g of P123 and 0.1g of hexamethyleneimine, dissolve in a mixed solution of 16.5ml of absol...

Embodiment 3

[0061] Example 3: Mesoporous "Z-Scheme" type Fe 2 o 3 / g -C 3 N 4 Preparation of composite system

[0062] 1. Preparation of g-C 3 N 4 catalyst of light

[0063] 1. Weigh urea, dry it in an oven at 80°C for 24 hours, grind it and put it into a crucible, cover it, and place it in a muffle furnace at 2°C min -1 The heating rate is from room temperature to 550°C, and calcined for 4h.

[0064] 2. Use 1mol L after taking it out -1 Soak and stir in nitric acid for 24 hours, filter, wash with distilled water 7-8 times until neutral, and dry in an oven at 80°C for 24 hours.

[0065] 3. Take out the sample and grind it, place it in a crucible, and calcinate it in a muffle furnace at 500°C for 4 hours without a cover to obtain mesoporous g-C 3 N 4 catalyst of light.

[0066] 2. Preparation of mesoporous “Z-Scheme” Fe 2 o 3 / g -C 3 N 4 Composite system

[0067] 1. Accurately weigh 0.2g of P123 and 0.1g of hexamethyleneimine, dissolve in a mixed solution of 16.5ml of absol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com