Method organic framework based on alginic acid electrospun fibers and preparation method thereof

A metal-organic framework and electrospun fiber technology, which is applied in the direction of spinning solution preparation, fiber type, fiber treatment, etc., can solve the problems of harsh growth conditions, uncontrollable reaction process, etc., achieve uniform shape, suitable for large-scale production, The effect of mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

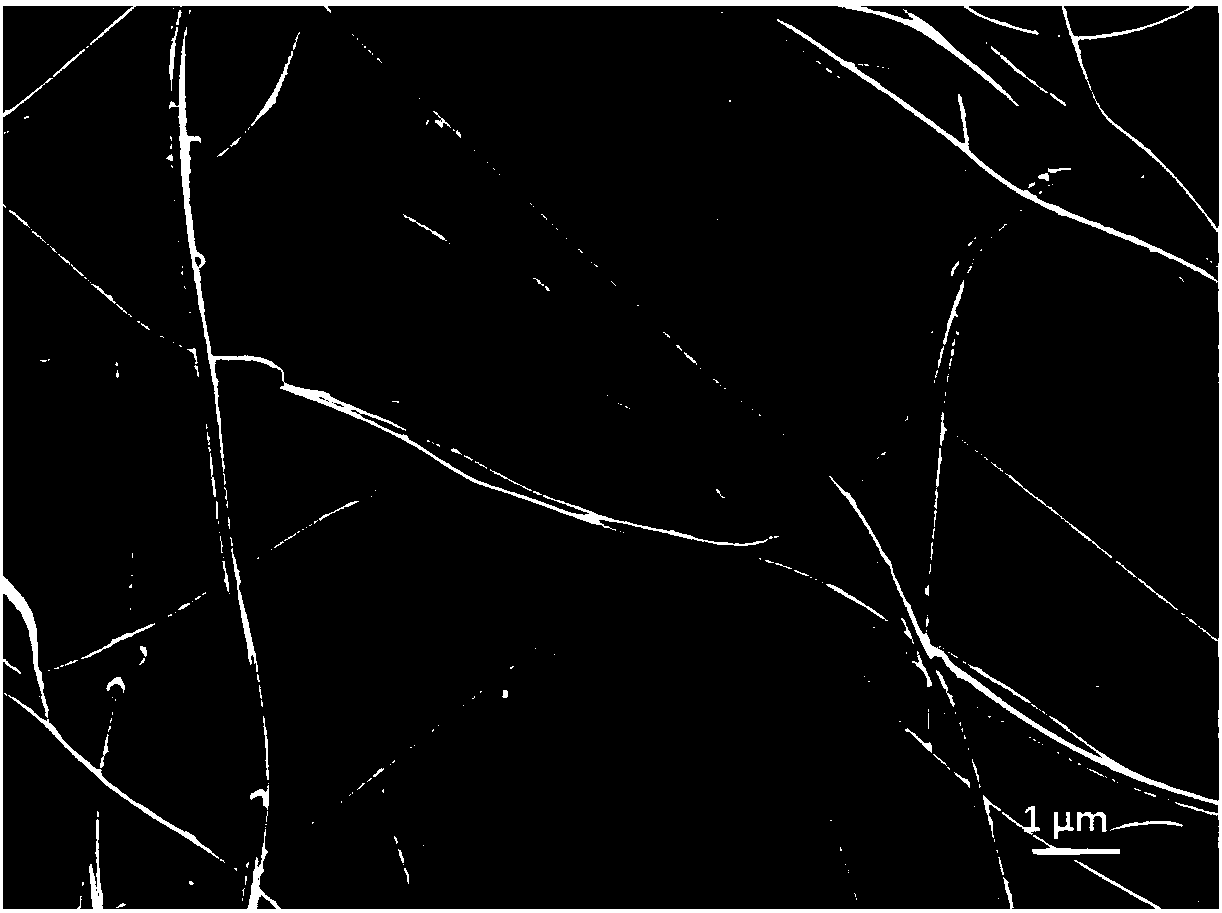

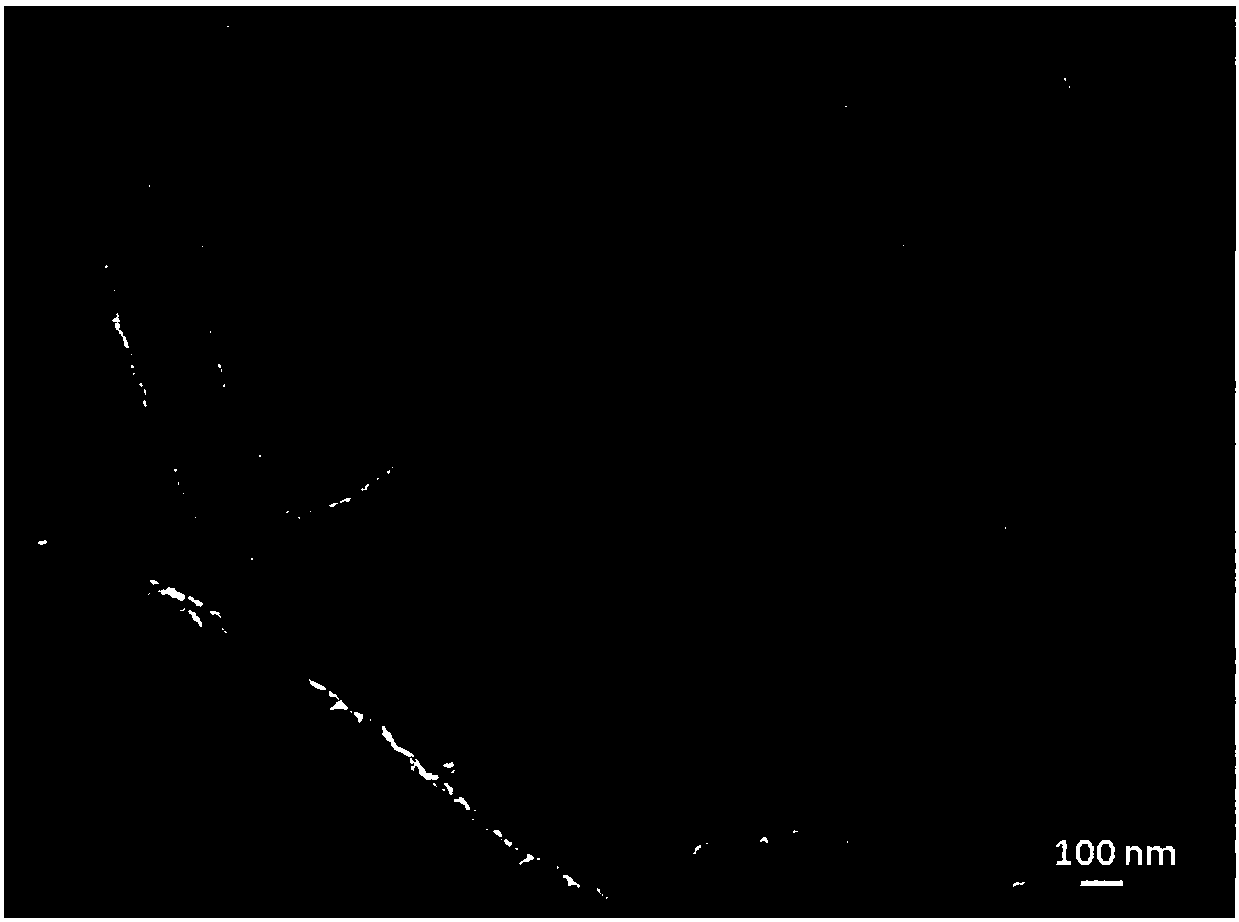

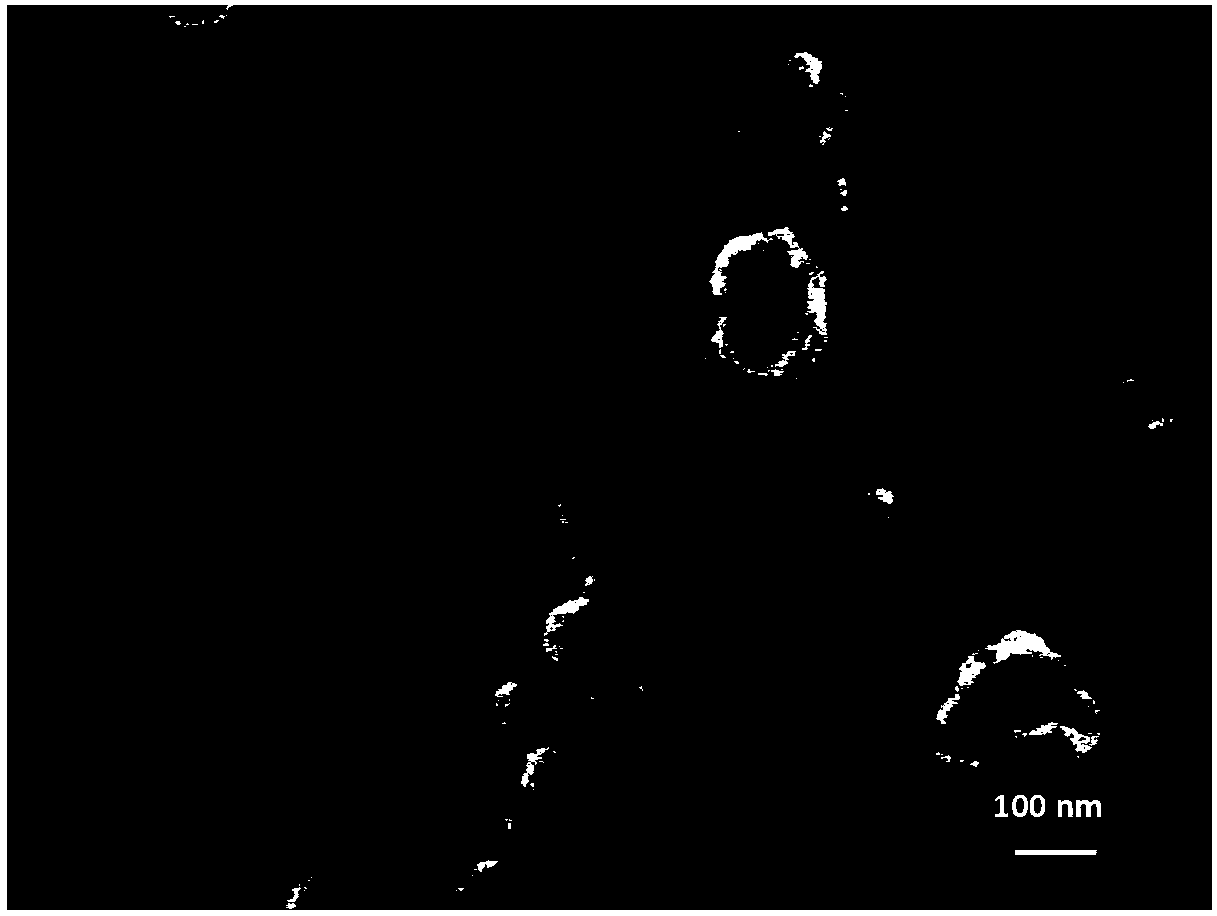

[0019] A method for preparing a metal-organic framework based on alginic acid electrospun fibers, comprising the following steps:

[0020] (1) Electrospun base nanofiber membrane: Sodium alginate and polyethylene oxide (PEO, average molecular weight 400w) were dissolved in deionized water to prepare 4wt% solutions respectively, and the two solutions of the gained were degassed by centrifugal degassing respectively, according to Mix the sodium alginate solution and the polyethylene oxide solution at a volume ratio of 3:2 and stir for 3 hours, add Triton-100 and dimethyl sulfoxide (DMSO) to the mixed solution, mix and stir for 3 hours, and centrifuge and deaerate to obtain the spinning precursor solution, the contents of Triton-100 and DMSO in the spinning precursor solution were 0.5wt% and 5wt%, stirred for 3 hours, centrifuged for defoaming, and set the parameters for electrospinning: the inner diameter of the needle was 0.2mm, and the receiving distance was 10cm. Voltage 15KV...

Embodiment 2

[0023] A method for preparing a metal-organic framework based on alginic acid electrospun fibers, comprising the following steps:

[0024] (1) Electrospun base nanofiber membrane: Sodium alginate and polyethylene oxide (PEO, average molecular weight 400w) were dissolved in deionized water to prepare 4wt% solutions respectively, and the two solutions of the gained were degassed by centrifugal degassing respectively, according to Mix the sodium alginate solution and the polyethylene oxide solution at a volume ratio of 3:2 and stir for 3 hours, add Triton-100 and dimethyl sulfoxide (DMSO) to the mixed solution, mix and stir for 3 hours, and centrifuge and deaerate to obtain the spinning precursor solution, the contents of Triton-100 and DMSO in the spinning precursor solution were 0.5wt% and 5wt%, stirred for 3 hours, centrifuged for defoaming, and set the parameters for electrospinning: the inner diameter of the needle was 0.2mm, and the receiving distance was 10cm. Voltage 15KV...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com