Preparation method of ultra-high purity aluminum sample for GDMS detection and impurity analysis method of ultra-high purity aluminum sample

A pure aluminum and sample technology, applied in the field of high-purity metal composition analysis, can solve the problems of long stable time of element detection values, unstable detection results, accumulation of surface impurities, etc. The effect of simple sample preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] According to a first aspect of the present invention, a method for preparing an ultra-high-purity aluminum sample for GDMS detection is provided, comprising the following steps:

[0034] Ultrasonic pickling is carried out on the ultra-high-purity aluminum sample to be tested with pickling solution. The pickling solution is mainly composed of nitric acid, hydrofluoric acid and water. The volume ratio of nitric acid, hydrofluoric acid and water is 1:(2~5) : (5~8).

[0035] GDMS is the abbreviation of glow discharge mass spectrometry (glow discharge mass spectrometry), which is an analytical method that uses a glow discharge source as an ion source to connect with a mass spectrometer for mass spectrometry.

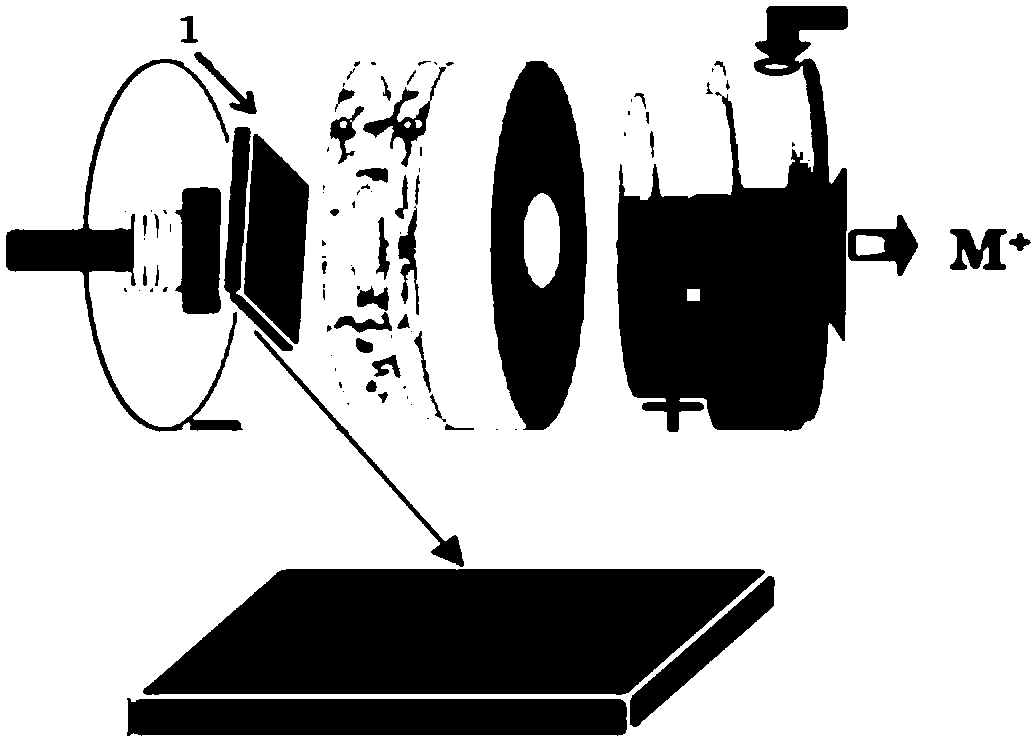

[0036] figure 1 A schematic diagram of the assay setup for GDMS samples, such as figure 1 As shown, GDMS is mainly composed of an ion source, a mass analyzer and a detection system. During detection, the measured sheet sample 1 with a flat surface is used as the cath...

Embodiment 1

[0079] A preparation method for an ultra-high-purity aluminum sample detected by GDMS, comprising the following steps:

[0080] (a) Surface treatment of the ultra-high-purity aluminum sample to be tested is carried out by turning or mechanical grinding to make the testing surface smooth;

[0081](b) Ultrasonic pickling is carried out on the surface-treated ultra-high-purity aluminum sample with pickling solution. The ultrasonic pickling time is 6 minutes, the ultrasonic pickling temperature is 20°C, and the ultrasonic power is 150W. Fluoric acid and water are mixed, and the volume ratio of nitric acid, hydrofluoric acid and water is 1:2:8;

[0082] (c) The ultra-high-purity aluminum samples after ultrasonic pickling were first washed with distilled water for 3 times and then with ethanol for 3 times, and then put into a drying oven and dried at 25°C for 30 minutes for later use.

Embodiment 2

[0084] A preparation method for an ultra-high-purity aluminum sample detected by GDMS, comprising the following steps:

[0085] (a) Surface treatment of the ultra-high-purity aluminum sample to be tested is carried out by turning or mechanical grinding to make the testing surface smooth;

[0086] (b) Ultrasonic pickling is carried out on the surface-treated ultra-high-purity aluminum sample with pickling solution. The ultrasonic pickling time is 3 minutes, the ultrasonic pickling temperature is 30°C, and the ultrasonic power is 150W. Fluoric acid and water are mixed, and the volume ratio of nitric acid, hydrofluoric acid and water is 1:3:8;

[0087] (c) The ultra-high-purity aluminum sample after ultrasonic pickling was washed 5 times with distilled water and then 5 times with ethanol, and then put into a drying oven and dried at 15°C for 45 minutes for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com