Method and device for high-throughput characterization of heat and structure during melting-solidification of crystalline materials

A technology of crystal materials, melting process, applied in the direction of measuring devices, thermal development of materials, analysis of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

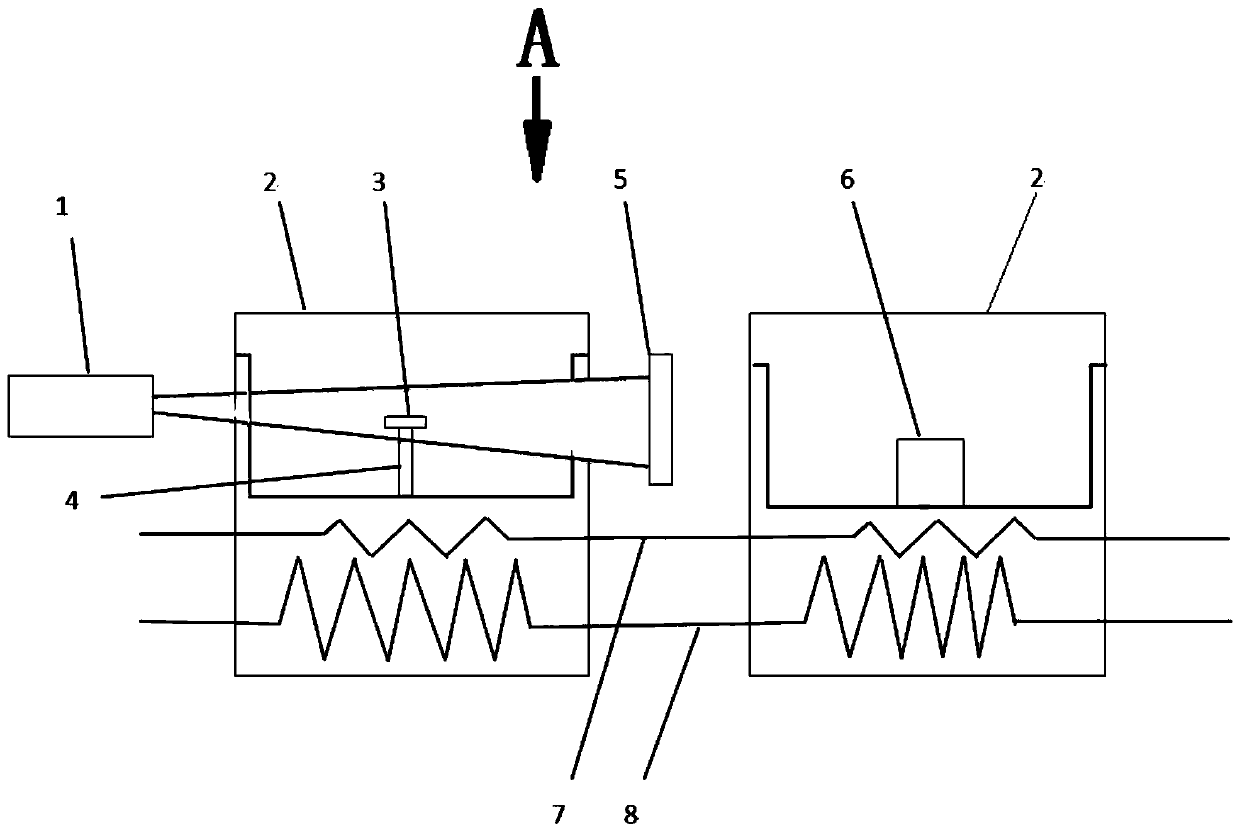

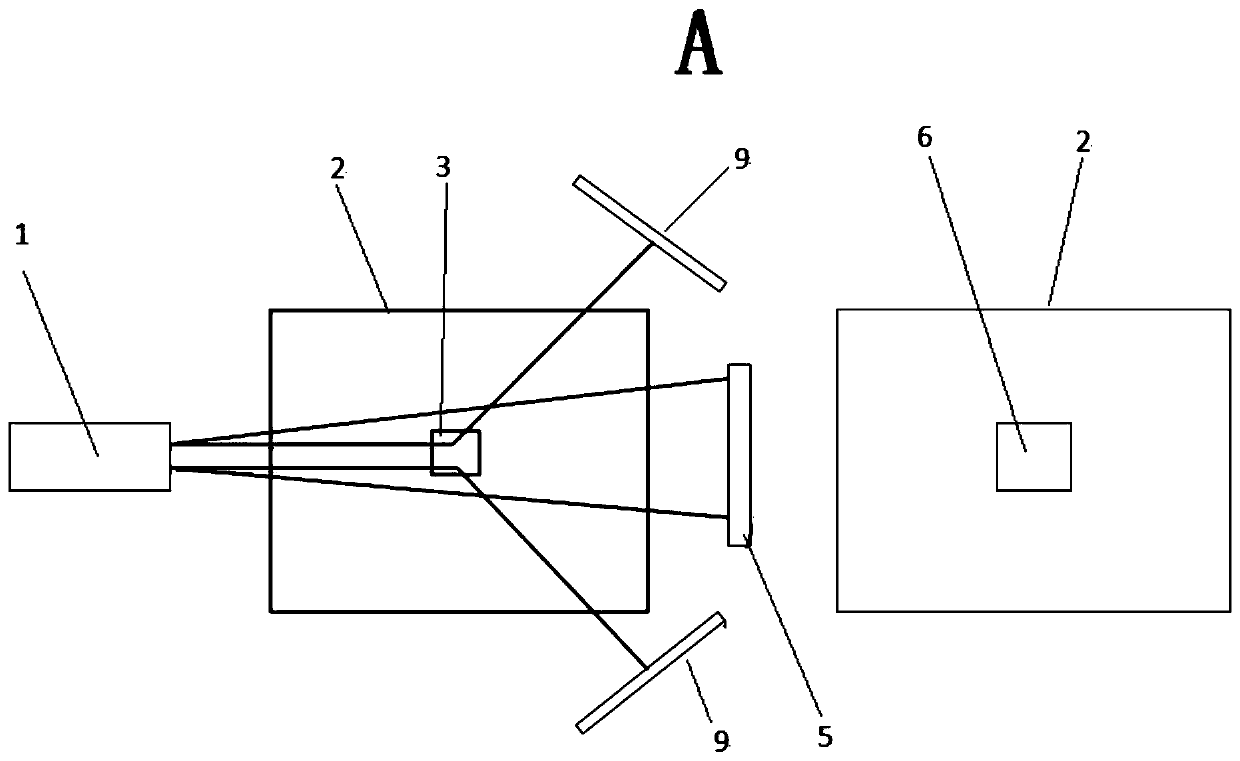

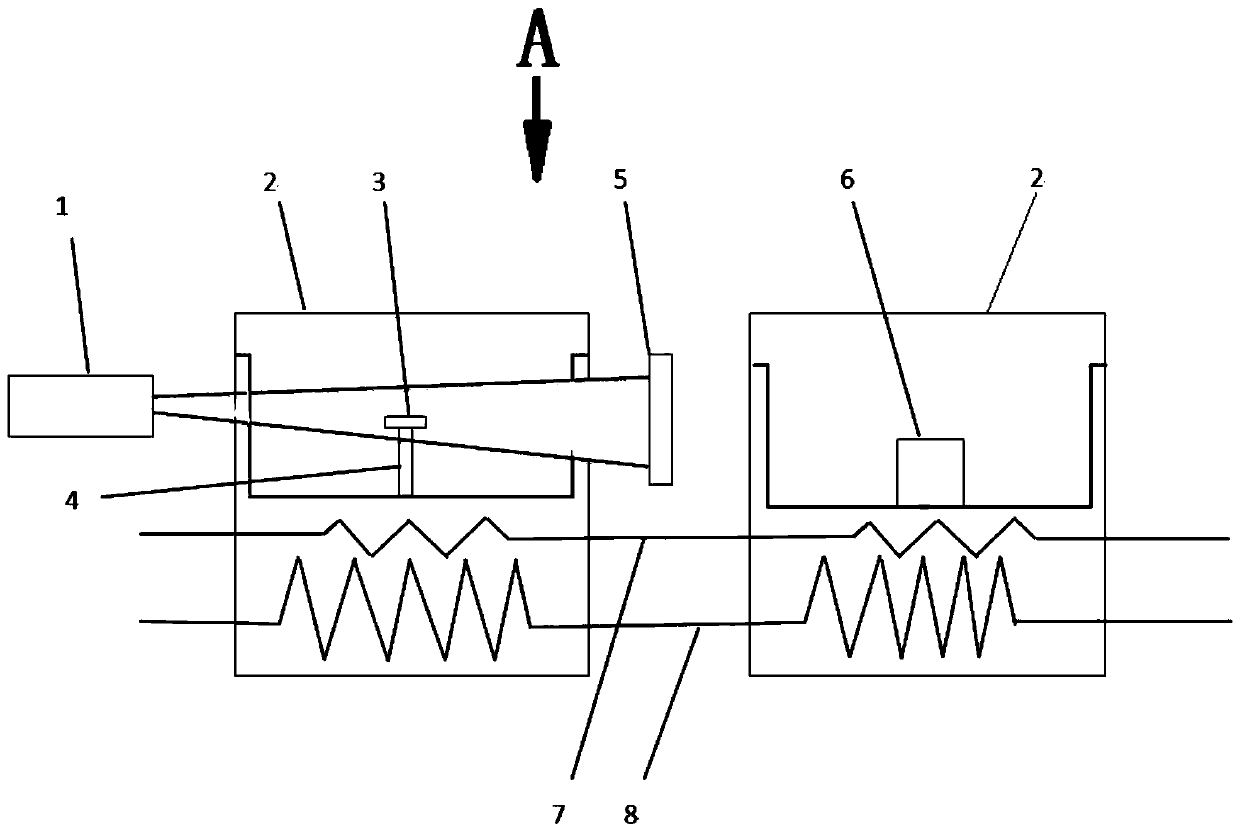

[0043] In this example, see figure 1 and figure 2 , a crystal melting-solidification high-throughput test and analysis device, mainly including two heating furnaces 2, a sample carrying device 3, a stage linkage device 4, an X-ray imaging device unit, an X-ray diffraction test device unit, a differential Composed of scanning calorimeter unit and main controller;

[0044] In the closed cavity of one of the heating furnaces 2, the sample carrying device 3 is set, and the AlSi 12 The crystal material to be tested is set on the sample carrying device 3, and the main controller can control the stage linkage device 4 to pull the sample carrying device 3 to rotate horizontally, thereby adjusting the AlSi on the sample carrying device 3. 12 The rotation angle of the crystal material to be measured; a reference object carrying device 6 is set in the closed inner cavity of another heating furnace 2, and an inert reference object is arranged on the reference object carrying device 6; th...

Embodiment 2

[0063] This embodiment is basically the same as Embodiment 1, especially in that:

[0064] In this embodiment, the main controller can also control the stage linkage device 4 to pull the sample carrying device 3 to perform a compound movement of horizontal rotation, horizontal displacement and lifting displacement, so that the crystal to be measured arranged on the sample carrying device 3 The material undergoes a spatial displacement transformation of the X, Y, and Z axes. The heating element for heating is made of iron-chromium-aluminum alloy; the heating resistance wire of the independent heating device 8 is made of iron-chromium-aluminum alloy; when the X-ray light source 1 performs X-ray irradiation, a transmission target and a reflection target are used, and the target material is tungsten; The protective gas used in the inert gas atmosphere in the heating furnace 2 is argon. The sample carrying device 3 can precisely rotate 360°, and the minimum rotation angle is less ...

Embodiment 3

[0067] This embodiment is basically the same as the previous embodiment, and the special features are:

[0068] In this embodiment, the relative position of the heating furnace 2 and the X-ray light source 1 is adjusted so that the distance between the heating furnace 2 and the X-ray light source 1 is the minimum value, so that the X-ray spot reaches a set small size, and the set High-resolution 2D or 3D tissue images. In this embodiment, when the stage linkage device 4 is operated, the distance between the furnace body device of the heating furnace 2 and the X-ray light source 1 is the minimum value, so that the X-ray light source 1 spot is smaller, and a higher resolution can be obtained. High 3D images. In this embodiment, differential scanning calorimetry is used to characterize the heat change during the crystal melting-solidification process in real time, and X-ray diffraction is used to analyze the structural information of the process in real time. During the crystal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com