Dry type flexible grinding and polishing method and matching cutter and device thereof

A grinding and polishing, flexible technology, used in grinding/polishing equipment, metal processing equipment, grinding/polishing safety devices, etc. Good effect, the effect of solving sewage discharge and equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

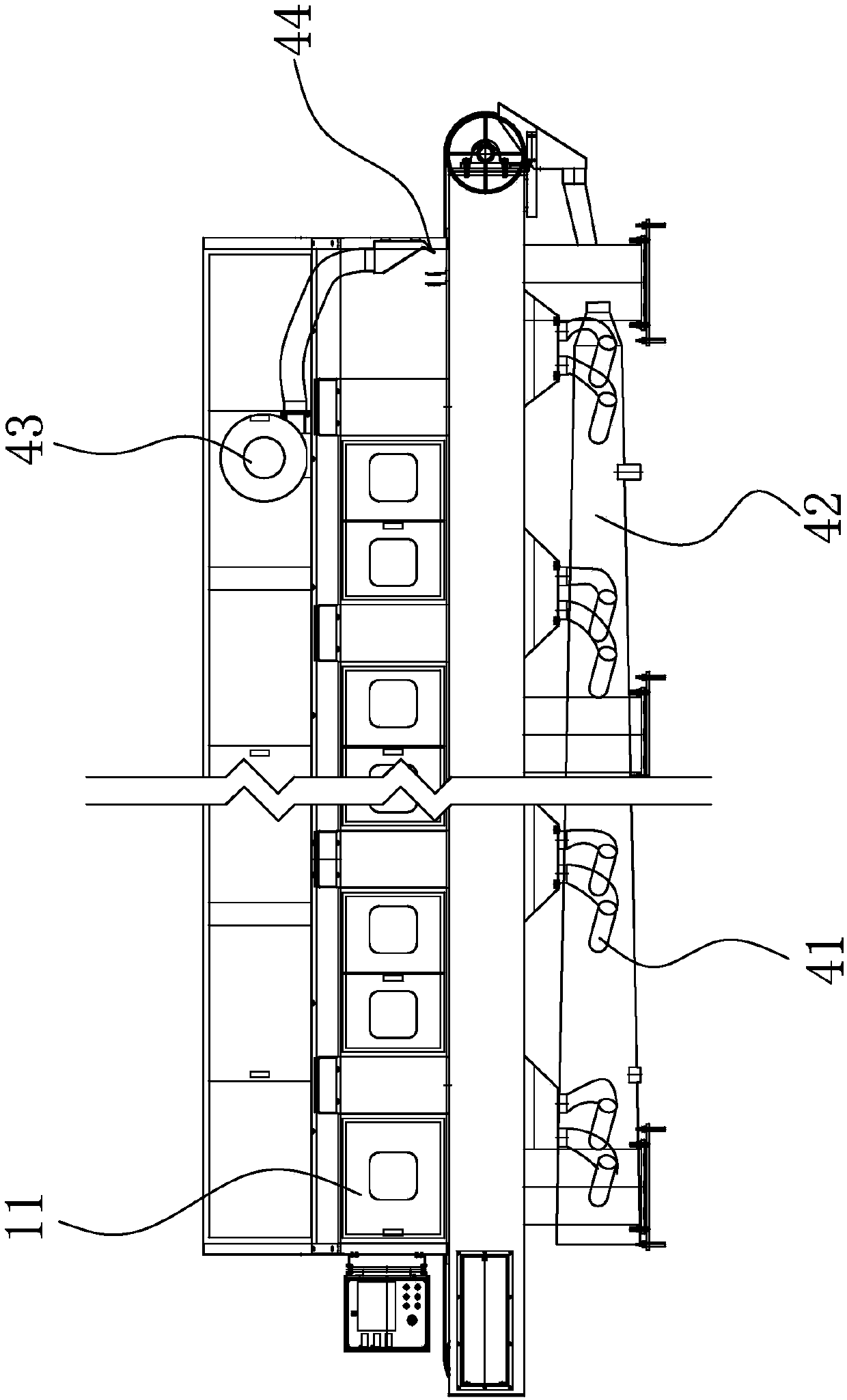

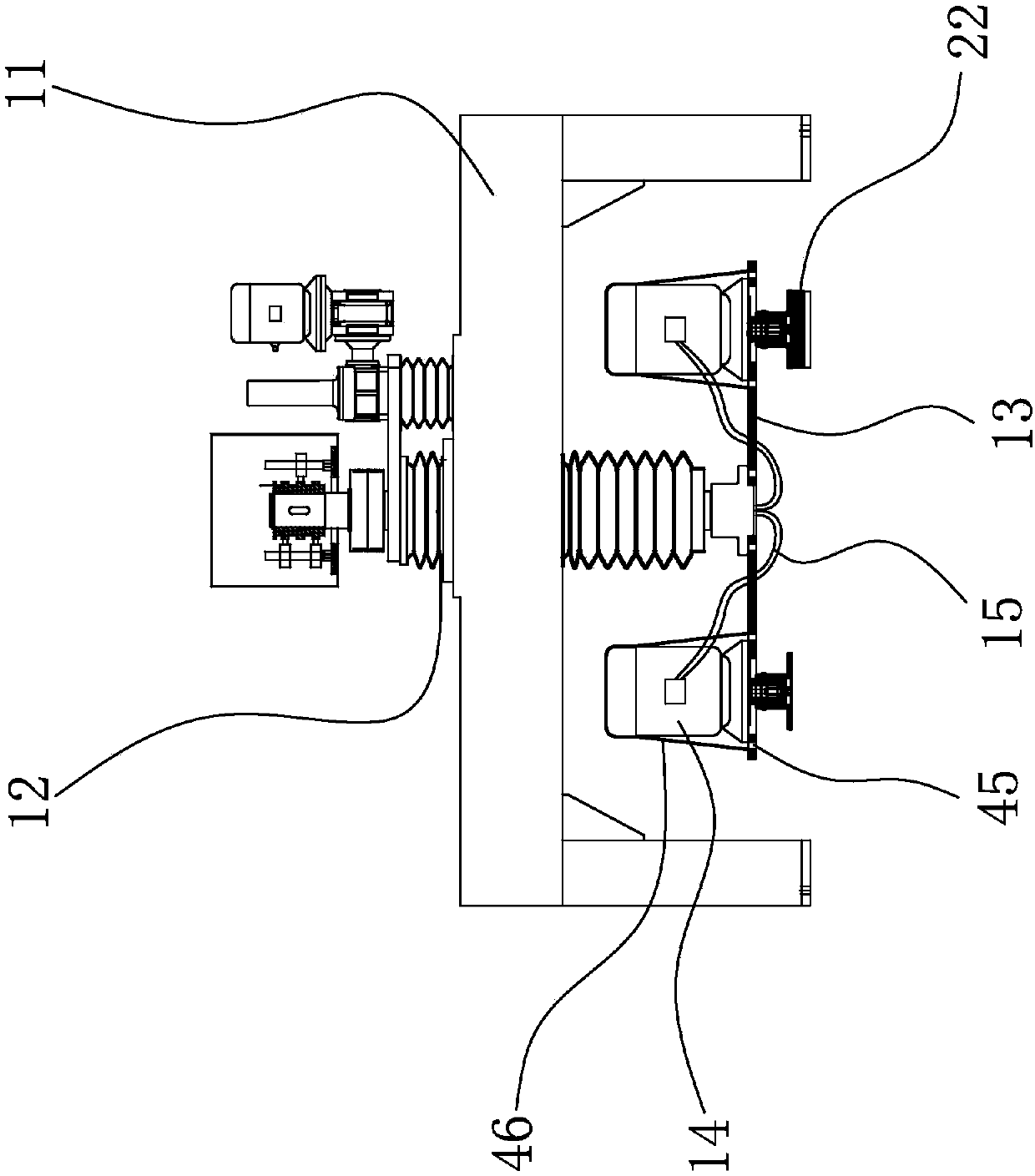

[0033] Embodiment 1, with reference to 1 and 2, a dry flexible grinding and polishing equipment, including a frame with a machine table, the machine table of the frame is provided with:

[0034] Grinding and polishing module, it comprises circulation mill mechanism, and described circulation mill mechanism comprises:

[0035] Grinding head support 11, it straddles on the frame;

[0036] The main shaft 12 passes through the grinding head support 11 vertically;

[0037] The revolving disk 13 is laid flat and its middle position is connected with the lower section of the main shaft 12,

[0038] The revolving disk 13 is provided with several grinding mold module installation positions near the edge;

[0039] A revolution motor, which is connected to the upper section of the main shaft, drives the main shaft to rotate;

[0040] Abrasive mold module, it comprises the self-rotating blank throwing motor 14 that is installed on the described abrasive mold module mounting position ac...

Embodiment 2

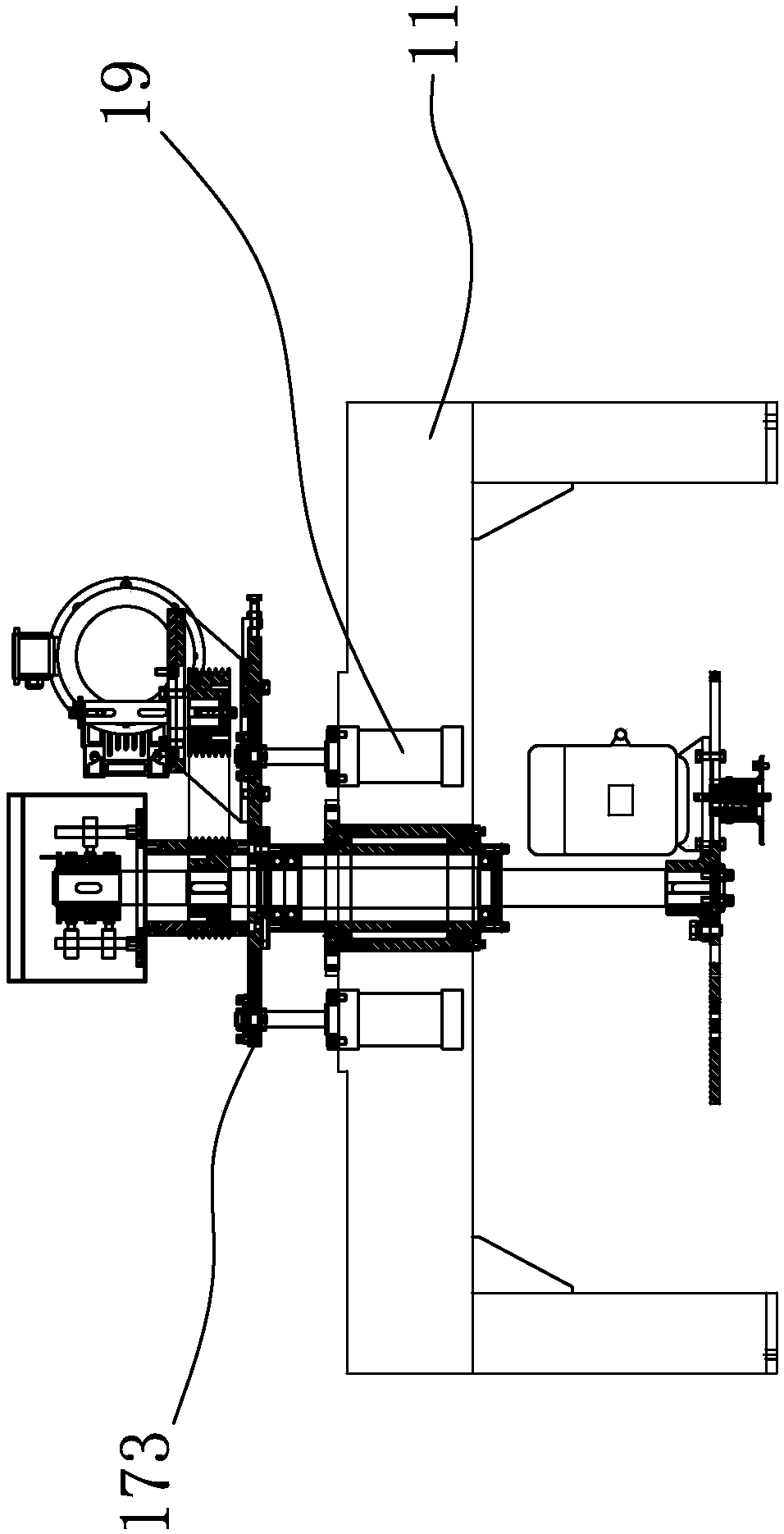

[0044] Embodiment 2, with reference to figure 1 , image 3 and Figure 4 , the difference from Embodiment 1 mainly focuses on the grinding and polishing module.

[0045] The grinding and polishing module also includes a fast lifting mechanism for the main shaft, including a connecting frame 173, a limit screw 171, a screw drive motor 172 and a cylinder 19. The connecting frame 173 is fixedly connected with the main shaft 12 axially, and the limit wire The screw bearing of the rod 171 is fixedly connected with the connecting frame 173 , and the screw drive motor 172 drives the limit screw 171 to rotate.

[0046] Furthermore, the quick-lifting mechanism for the main shaft also includes a buffer pad 174 , and the buffer pad 174 is arranged at the bottom end of the limit screw rod 171 above the grinding head support 11 .

[0047] As a further preferred embodiment, the grinding mold module further includes an air-cooling outlet, the air-cooling outlet is located next to the grin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com