Optical polyester film

A technology of optical polyester film and polyester base film, applied in the direction of chemical instruments and methods, coatings, layered products, etc., can solve the problems of inconvenient processing, affecting the light transmittance of polyester film, restrictions, etc., to prevent The effect of light transmittance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

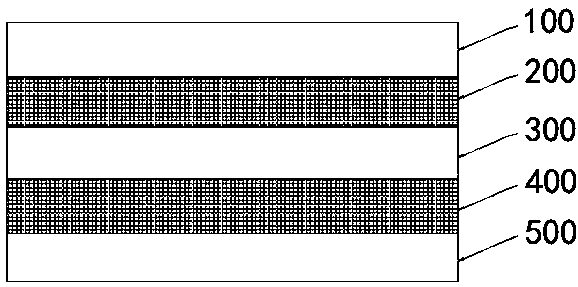

[0020] An optical polyester film, comprising a first outer coating 100, a first surface layer 200, a polyester base film core layer 300, a second surface layer 400 and a second outer coating 500 arranged sequentially from inside to outside; The ester-based film core layer 300 is obtained by biaxial stretching of copolyester, and the first outer coat 100 and the second outer coat 500 contain colloidal silica; the polyester base film core layer 300 of the film The thickness is 180 μm, and the light transmittance is 95.0%. The thickness of the first surface layer 200 and the second surface layer 400 is controlled at 25 μm, and the thickness of the first outer coating layer 100 and the second outer coating layer 500 is controlled at 0.35 μm.

Embodiment 2

[0022] An optical polyester film, comprising a first outer coating 100, a first surface layer 200, a polyester base film core layer 300, a second surface layer 400 and a second outer coating 500 arranged sequentially from inside to outside; The ester-based film core layer 300 is obtained by biaxial stretching of copolyester, and the first outer coat 100 and the second outer coat 500 contain colloidal silica; the polyester base film core layer 300 of the film The thickness is 125 μm, the light transmittance is 90.0%, the thickness of the first surface layer 200 and the second surface layer 400 is controlled at 6 μm, and the thickness of the first outer coating layer 100 and the second outer coating layer 500 is controlled at 0.25 μm.

[0023] The copolyester is a copolyester formed by copolymerization of polyethylene glycol, propylene glycol and 1,4-cyclohexanedimethanol with two dibasic acids.

Embodiment 3

[0025] An optical polyester film, comprising a first outer coating 100, a first surface layer 200, a polyester base film core layer 300, a second surface layer 400 and a second outer coating 500 arranged sequentially from inside to outside; The ester-based film core layer 300 is obtained by biaxial stretching of copolyester, and the first outer coat 100 and the second outer coat 500 contain colloidal silica; the polyester base film core layer 300 of the film The thickness is 180 μm, and the light transmittance is 93.0%. The thickness of the first surface layer 200 and the second surface layer 400 is controlled at 20 μm, and the thickness of the first outer coating layer 100 and the second outer coating layer 500 is controlled at 0.20 μm.

[0026] The copolyester is a copolyester formed by copolymerization of ethylene glycol, polyethylene glycol and dibasic acid.

[0027] The dibasic acid is isophthalic acid, terephthalic acid or 2,6-naphthalene dicarboxylic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com