Preparation method of nano soil remediation conditioner

A soil remediation and conditioning agent technology, applied in the field of preparation of nano soil remediation conditioners, can solve problems such as residues, hidden dangers to health, crop yield reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

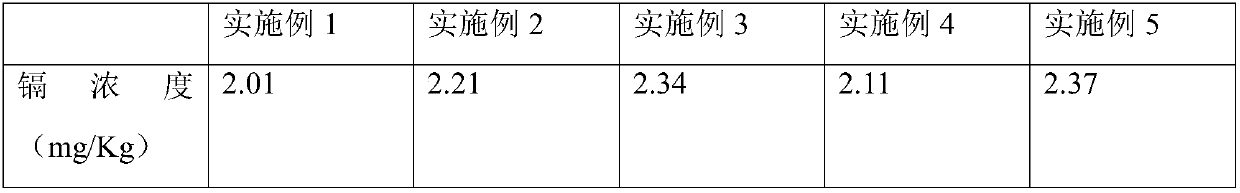

Examples

Embodiment 1

[0034] A preparation method of a nanometer soil restoration conditioner, comprising the steps of:

[0035] (1) At a temperature of 55°C, dry the wheat straw, wheat straw, corngrass and emperor bamboo grass until the water content of the wheat straw, wheat straw, corn grass and emperor bamboo grass is ≤20%;

[0036] Wherein, the mass ratio of wheat straw, wheat straw, corn grass and emperor bamboo grass is 1:1:2:3;

[0037] (2) Grinding the dried wheat straw, wheat straw, corngrass, and emperor bamboo grass into particles with a particle size of 10mm, and then mixing them uniformly to form a mixture;

[0038] (3) Mix the mixture, manure, EM bacteria and water at a mass ratio of 10:1:0.1:1, and then ferment anaerobically at a temperature of 50°C for 32 hours to obtain the first raw material;

[0039] Then raise the temperature of the first raw material to 90°C, keep it warm for 10 minutes, and then cool down to 30°C;

[0040] (4) The first raw material and water are mixed acco...

Embodiment 2

[0049] A preparation method of a nanometer soil restoration conditioner, comprising the steps of:

[0050] (1) At a temperature of 60°C, dry the wheat straw, wheat straw, corngrass and emperor bamboo grass until the moisture content of the wheat straw, wheat straw, corn grass and emperor bamboo grass is ≤20%;

[0051] Wherein, the mass ratio of wheat straw, wheat straw, corn grass and emperor bamboo grass is 1:1:2:3;

[0052] (2) Grinding the dried wheat straw, wheat straw, corngrass, and emperor bamboo grass into particles with a particle size of 5 mm, and then mixing them uniformly to form a mixture;

[0053] (3) Mix the mixture, manure, EM bacteria and water at a mass ratio of 10:1:0.1:1, and then ferment anaerobically at a temperature of 50°C for 35 hours to obtain the first raw material;

[0054] Then raise the temperature of the first raw material to 90°C, keep it warm for 10 minutes, and then cool down to 30°C;

[0055] (4) The first raw material and water are mixed a...

Embodiment 3

[0064] A preparation method of nanometer soil repair conditioner, is characterized in that, comprises the steps:

[0065] (1) At a temperature of 60°C, dry the wheat straw, wheat straw, corngrass and emperor bamboo grass until the moisture content of the wheat straw, wheat straw, corn grass and emperor bamboo grass is ≤20%;

[0066] Wherein, the mass ratio of wheat straw, wheat straw, corn grass and emperor bamboo grass is 1:1:2:3;

[0067] (2) Grinding the dried wheat straw, wheat straw, corngrass, and emperor bamboo grass into particles with a particle size of 9 mm, and then mixing them uniformly to form a mixture;

[0068] (3) Mix the mixture, manure, EM bacteria and water in a mass ratio of 10:1:0.1:1, and then ferment anaerobically at a temperature of 52°C for 31 hours to obtain the first raw material;

[0069] Then raise the temperature of the first raw material to 90°C, keep it warm for 7 minutes, and then cool it down to 25°C;

[0070] (4) The first raw material and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com