Calcium-magnesium fertilizer, preparation method and application thereof

A fertilizer and calcium-magnesium technology, applied in the field of calcium-magnesium fertilizer and its preparation, can solve the problems of not being able to use a large amount of vinegar slag, high acidity of vinegar slag, and polluting the environment, and achieve remarkable fertilizer efficiency, solve soil deterioration, and improve soil effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

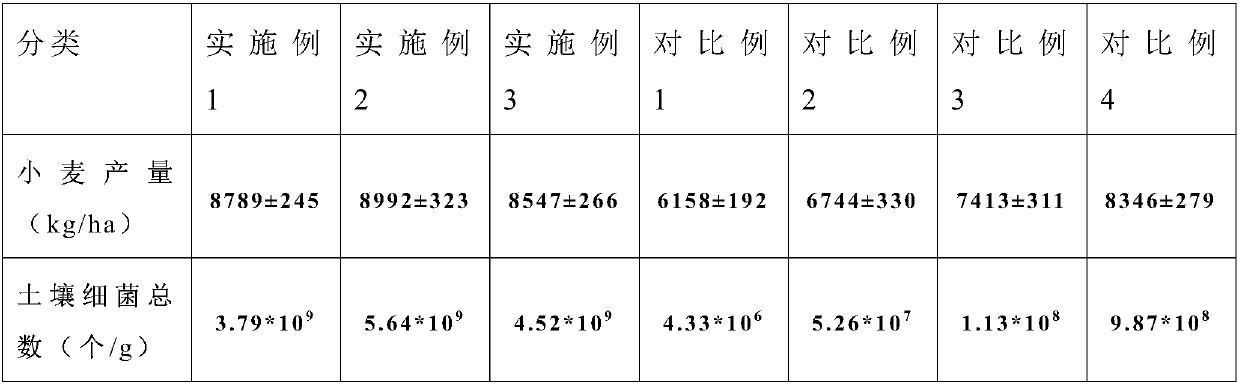

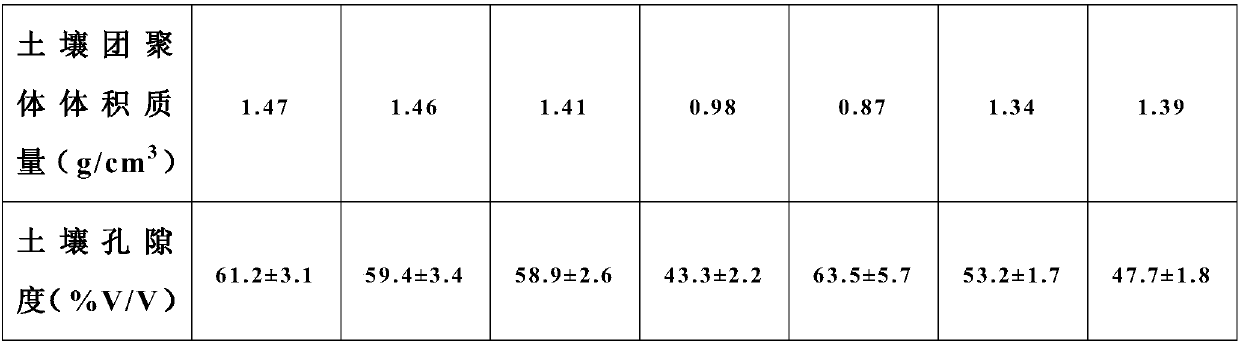

Embodiment 1

[0031] The preparation of embodiment 1 calcium magnesium fertilizer

[0032] This example provides a kind of calcium-magnesium fertilizer, in parts by weight, its raw material formula comprises that particle size is 2 parts of calcium / magnesium ore powder (the dolomite powder produced by Jinmao Mining Co., Ltd. of Qingyang County, Anhui Province) with particle size of 80 mesh, and particle size is 10 mesh vinegar 1 part of slag (Zhenjiang Hengxin Fertilizer Technology Co., Ltd., vinegar residue after drying treatment) and 1 part of agricultural enzyme fermentation liquid, wherein the raw material formula of the agricultural enzyme fermentation liquid includes 1 part of livestock manure, 0.8 part of waste molasses (Changshu Guangxi Guigang sugarcane chemical factory product distributed by Xinyue Chemical Sales Co., Ltd.), 0.1 part of urea ("Linggu brand" produced by Jiangsu Linggu Chemical Co., Ltd. distributed by Suzhou Oris Chemical Material Co., Ltd.) and 8 parts of water, D...

Embodiment 2

[0040] The preparation of embodiment 2 calcium magnesium fertilizer

[0041] This example provides a kind of calcium-magnesium fertilizer, in parts by weight, its raw material formula comprises that particle size is 100 mesh calcium / magnesium ore powder 2.5 parts (dolomite powder produced by Jinmao Mining Co., Ltd., Qingyang County, Anhui Province), particle size is 20 mesh vinegar 1 part of slag (Zhenjiang Hengxin Fertilizer Technology Co., Ltd., vinegar residue after drying treatment) and 1 part of agricultural enzyme fermentation liquid, wherein the raw material formula of the agricultural enzyme fermentation liquid includes 1 part of livestock manure, 1 part of waste molasses (Changshu Guangxi Guigang sugarcane chemical factory products distributed by Xinyue Chemical Sales Co., Ltd.), 0.24 parts of urea ("Linggu brand" produced by Jiangsu Linggu Chemical Co., Ltd. distributed by Suzhou Oris Chemical Materials Co., Ltd.) and 10 parts of water, Described water is the water c...

Embodiment 3

[0049] The preparation of embodiment 3 calcium magnesium fertilizer

[0050] This example provides a kind of calcium-magnesium fertilizer, in parts by weight, its raw material formula comprises particle size and is 3 parts of calcium / magnesium ore powder (the dolomite powder produced by Jinmao Mining Co., Ltd. of Qingyang County, Anhui Province) that particle size is 120 mesh, and particle size is 30 mesh vinegar 1 part of slag (Zhenjiang Hengxin Fertilizer Technology Co., Ltd., vinegar residue after drying treatment) and 1 part of agricultural enzyme fermentation liquid, wherein the raw material formula of the agricultural enzyme fermentation liquid includes 1 part of livestock manure, 1.2 parts of waste molasses (Changshu Guangxi Guigang sugarcane chemical factory products distributed by Xinyue Chemical Sales Co., Ltd.), 0.4 parts of urea ("Linggu brand" produced by Jiangsu Linggu Chemical Co., Ltd. distributed by Suzhou Oris Chemical Materials Co., Ltd.) and 12 parts of water,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com