Non-ionic surfactant and preparation method thereof

A non-ionic surfactant and active agent technology, applied in the field of synthesis of non-ionic surfactants, can solve the problems of low yield, long reaction time, high cost, etc., and achieve the effect of simple production process, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

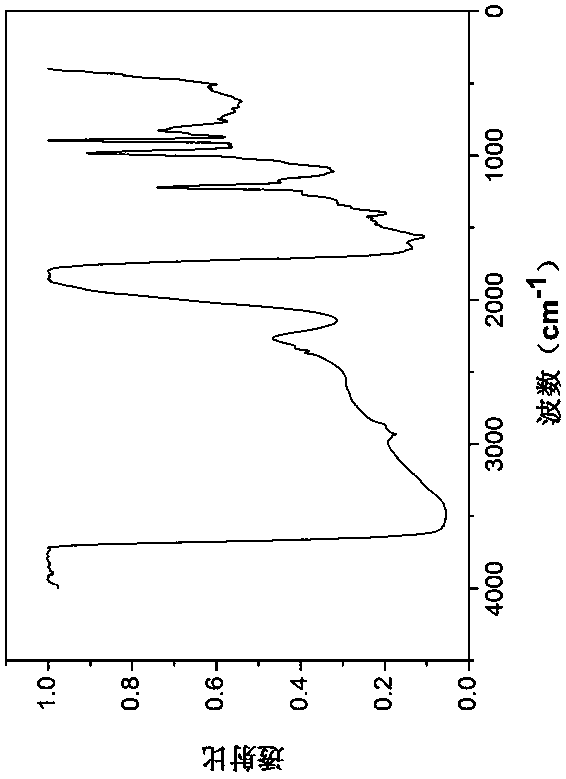

Embodiment 1

[0020] The preparation method of nonionic surfactant

[0021] (1) Add 0.02mol of adipic acid and 0.025mol of diethylene glycol bis(3-aminopropyl)ether into a 250ml three-necked flask, mix well, and react in an oil bath at 120°C under the protection of normal pressure nitrogen for 2 hours under stirring conditions. After the reaction, cool to room temperature in a nitrogen stream to obtain Intermediate 1, add 30ml of ethanol, and sonicate until completely dissolved to obtain Solution 1.

[0022] (2) Dissolve 0.01mol of HMDI and 0.005mol of polyetheramine D2000 in 30ml of ethanol respectively, place them in an ice-water bath, and add the ethanol solution of polyetheramine D2000 dropwise to the ethanol solution of HMDI in an ice-water bath environment, After the dropwise addition, solution 2 was obtained.

[0023] (3) Take another clean empty beaker, add solution 1 and solution 2 alternately dropwise to it under stirring condition, and obtain solution 3 after the addition is com...

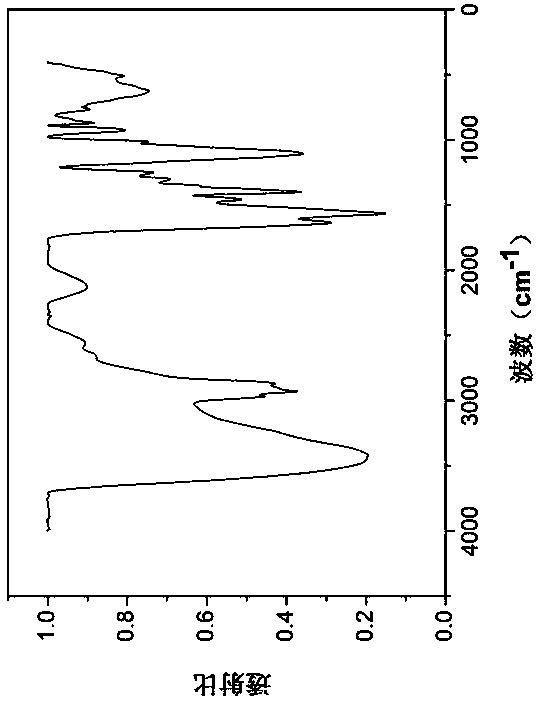

Embodiment 2

[0027] The preparation method of nonionic surfactant

[0028] (1) Add 0.04mol adipic acid and 0.045mol diethylene glycol bis(3-aminopropyl)ether into a 250ml three-necked flask, mix well, and react in an oil bath at 120°C under the protection of atmospheric nitrogen for 2 hours under stirring conditions. After the reaction, cool to room temperature in a nitrogen stream to obtain intermediate 2, add 30ml of ethanol, and sonicate until completely dissolved to obtain solution 1'.

[0029] (2) Dissolve 0.01mol of HMDI and 0.005mol of polyetheramine D2000 in 30ml of ethanol respectively, place them in an ice-water bath, and add the ethanol solution of polyetheramine D2000 dropwise to the ethanol solution of HMDI in an ice-water bath environment, After the dropwise addition, solution 2' was obtained.

[0030] (3) Take another clean empty beaker, add solution 1' and solution 2' alternately dropwise to it under stirring condition, obtain solution 3' after the dropwise addition, remov...

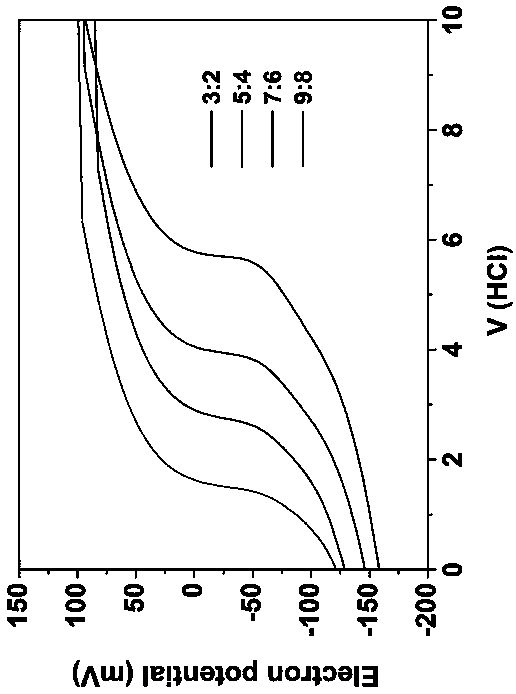

Embodiment 3

[0032] The preparation method of nonionic surfactant

[0033] (1) Add 0.02 mol of adipic acid and 0.2 mol of diethylene glycol bis(3-aminopropyl) ether into a 250ml three-neck flask, mix well, and react in an oil bath at 120°C under the protection of atmospheric nitrogen for 2 hours under stirring conditions. After the reaction, cool to room temperature in a nitrogen stream to obtain intermediate 3, add 30ml of ethanol, and sonicate until completely dissolved to obtain solution 1''.

[0034] (2) Dissolve 0.01mol of HMDI and 0.005mol of polyetheramine D2000 in 30ml of ethanol respectively, place them in an ice-water bath, and add the ethanol solution of polyetheramine D2000 dropwise to the ethanol solution of HMDI in an ice-water bath environment, After the dropwise addition was complete, solution 2'' was obtained.

[0035] (3) Take another clean empty beaker, add solution 1'' and solution 2'' alternately dropwise under stirring conditions, and obtain solution 3'' after the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com