Multifunctional antibacterial film and preparation method thereof

An antibacterial and multifunctional technology, applied in the field of biomedicine, can solve the problems of poor safety, poor bonding force, and difficult film uniformity in wet silver plating, and achieve guaranteed service life, improved sterilization effect, and excellent chemical stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

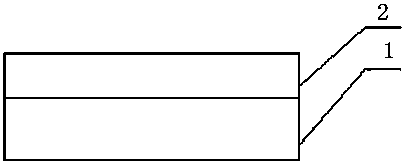

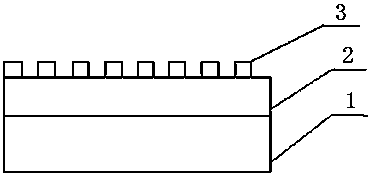

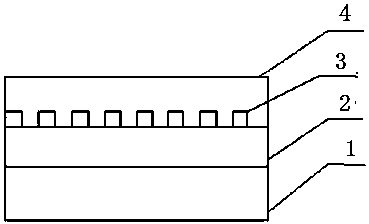

[0032] as attached Figure 1-5 As shown, a multifunctional antibacterial film includes a substrate 1 covered with a layer of silver film 2 on the substrate 1 covered with a layer of TiO 2 Nanoparticles 3, TiO 2 The nanoparticles 3 are covered with a polytetrafluoroethylene film 4 , and the surface of the polytetrafluoroethylene film 4 is provided with grooves 5 .

[0033] The thickness of the silver film 2 is 200-300 nm, and the thickness of the polytetrafluoroethylene film 4 is 200-300 nm.

[0034] As the preparation method of above-mentioned multifunctional antibacterial film, concrete steps are as follows:

[0035] (1) Silver-plated film: silver-plated film on the substrate;

[0036] (2) Spray TiO2 2 Nanoparticles: Spray TiO on the surface of the silver film 2 nanoparticles;

[0037] (3) PTFE coating: with TiO 2 The surface of the silver film of nanoparticles is coated with polytetrafluoroethylene film;

[0038] (4) Embossing: embossing grooves on the PTFE film.

...

Embodiment 2

[0047] A multifunctional antibacterial film, comprising a substrate 1 covered with a layer of silver film 2 covered with a layer of TiO 2 Nanoparticles 3, TiO 2 The nanoparticles 3 are covered with a polytetrafluoroethylene film 4 , and the surface of the polytetrafluoroethylene film 4 is provided with grooves 5 .

[0048] The thickness of the silver film 2 is 200 nm, and the thickness of the polytetrafluoroethylene film 4 is 200 nm.

[0049]As the preparation method of above-mentioned multifunctional antibacterial film, concrete steps are as follows:

[0050] (1) Silver-coated film: The silver film is plated on the substrate by magnetron sputtering coating method. The process conditions of magnetron sputtering coating film are as follows: a silver target with a thickness of Φ60mm and a thickness of 4mm is used, the target distance is adjusted to 60mm, and the power is 100W, DC mode sputtering.

[0051] (2) Spray TiO2 2 Nanoparticles: Spray TiO on the surface of the silver...

Embodiment 3

[0055] A multifunctional antibacterial film, comprising a substrate 1 covered with a layer of silver film 2 covered with a layer of TiO 2 Nanoparticles 3, TiO 2 The nanoparticles 3 are covered with a polytetrafluoroethylene film 4 , and the surface of the polytetrafluoroethylene film 4 is provided with grooves 5 .

[0056] The thickness of the silver film 2 is 220 nm, and the thickness of the polytetrafluoroethylene film 4 is 220 nm.

[0057] As the preparation method of above-mentioned multifunctional antibacterial film, concrete steps are as follows:

[0058] (1) Silver-coated film: The silver film is plated on the substrate by magnetron sputtering coating method. The process conditions of magnetron sputtering coating film are as follows: a silver target with a thickness of Φ60mm and a thickness of 4.5mm is used, the target distance is adjusted to 60mm, and the power 110W, DC mode sputtering.

[0059] (2) Spray TiO2 2 Nanoparticles: Spray TiO on the surface of the silver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com