Composite food preservative and preparation method thereof

A composite food and preservative technology, applied in food preservation, food ingredients as antimicrobial preservation, food science, etc., can solve problems such as adverse effects on the ecological environment, adverse effects on food flavor, and adverse effects on the human body, and achieve long-lasting effects Long time, extended food shelf life, low cost of raw materials and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

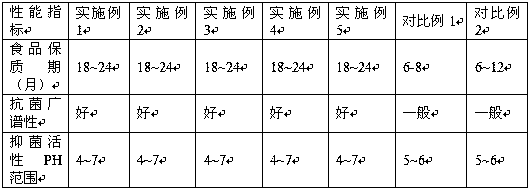

Examples

Embodiment 1

[0041] (1) Wash bitter gourd and Platycodon grandiflorum leaves, chop them up, mix them with peptone, corn flour and glucose, ferment at 30°C for 48 hours, use a centrifugal filter to remove the filter residue, and obtain a supernatant; in parts by weight of fermented products, of which 39 parts of bitter gourd, 30 parts of bellflower leaves, 25 parts of peptone, 3.5 parts of corn flour, and 0.5 part of glucose; bitter gourd is bitter gourd; peptone is soybean peptone;

[0042] (2) Add soluble starch to the supernatant of step (1), stir until fully dissolved, filter to obtain filtrate; the mixing mass ratio of soluble starch to supernatant is 1:3;

[0043] (3) Wash the sorbet and apple, remove the core, cut into pieces, mix with the filtrate of step (2), and use an industrial juicer to squeeze the juice to obtain the juice; in parts by weight of the mixture, 25 parts of sorbet, 25 parts, 50 parts of filtrate; the industrial juice extractor is a screw type juice extractor;

[...

Embodiment 2

[0048] (1) Wash bitter gourd and Platycodon grandiflorum leaves, chop them up, mix them with peptone, corn flour and glucose, ferment at 30°C for 48 hours, use a centrifugal filter to remove the filter residue, and obtain a supernatant; in parts by weight of fermented products, of which 34 parts of bitter gourd, 40 parts of bellflower leaves, 20 parts of peptone, 4 parts of corn flour, 0.5 part of glucose; bitter gourd is big top bitter gourd; peptone is blood peptone;

[0049] (2) Add soluble starch to the supernatant of step (1), stir until fully dissolved, filter to obtain filtrate; the mixing mass ratio of soluble starch to supernatant is 1:2;

[0050] (3) Wash the sorbets and apples, remove cores, cut into pieces, mix them with the filtrate of step (2), and use an industrial juicer to squeeze the juice to obtain juice; in parts by weight of the mixture, 30 parts of sorbets, 30 parts, 40 parts of filtrate; the industrial juicer is a vacuum bladder juicer;

[0051] (4) Mix...

Embodiment 3

[0055] (1) Wash bitter gourd and Platycodon grandiflorum leaves, chop them up, mix them with peptone, corn flour and glucose, ferment at 28°C for 65 hours, use a centrifugal filter to remove the filter residue, and obtain a supernatant; in parts by weight of fermented products, of which 40 parts of bitter gourd, 30 parts of bellflower leaves, 22 parts of peptone, 5 parts of corn flour, 0.5 part of glucose; bitter gourd is big top bitter gourd; peptone is fish peptone;

[0056] (2) Add soluble starch to the supernatant of step (1), stir until fully dissolved, filter to obtain filtrate; the mixing mass ratio of soluble starch to supernatant is 1:3;

[0057] (3) Wash the sorbets and apples, remove cores, cut into pieces, mix them with the filtrate in step (2), and use an industrial juicer to squeeze the juice to obtain juice; in parts by weight of the mixture, 28 parts of sorbets, 25 parts, 47 parts of filtrate; the industrial juicer is a cup juicer;

[0058] (4) Mix the squeeze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com