Acrylamide copolymer as well as preparation method and application thereof

An acrylamide copolymer and acrylamide copolymerization technology are applied in the directions of chemical instruments and methods, drilling compositions, etc., and can solve the problems of difficult synthesis of macromonomers, complicated synthesis steps, unfavorable polymer migration and movement, and the like. Good water solubility and low temperature stability, increasing hydration radius and increasing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

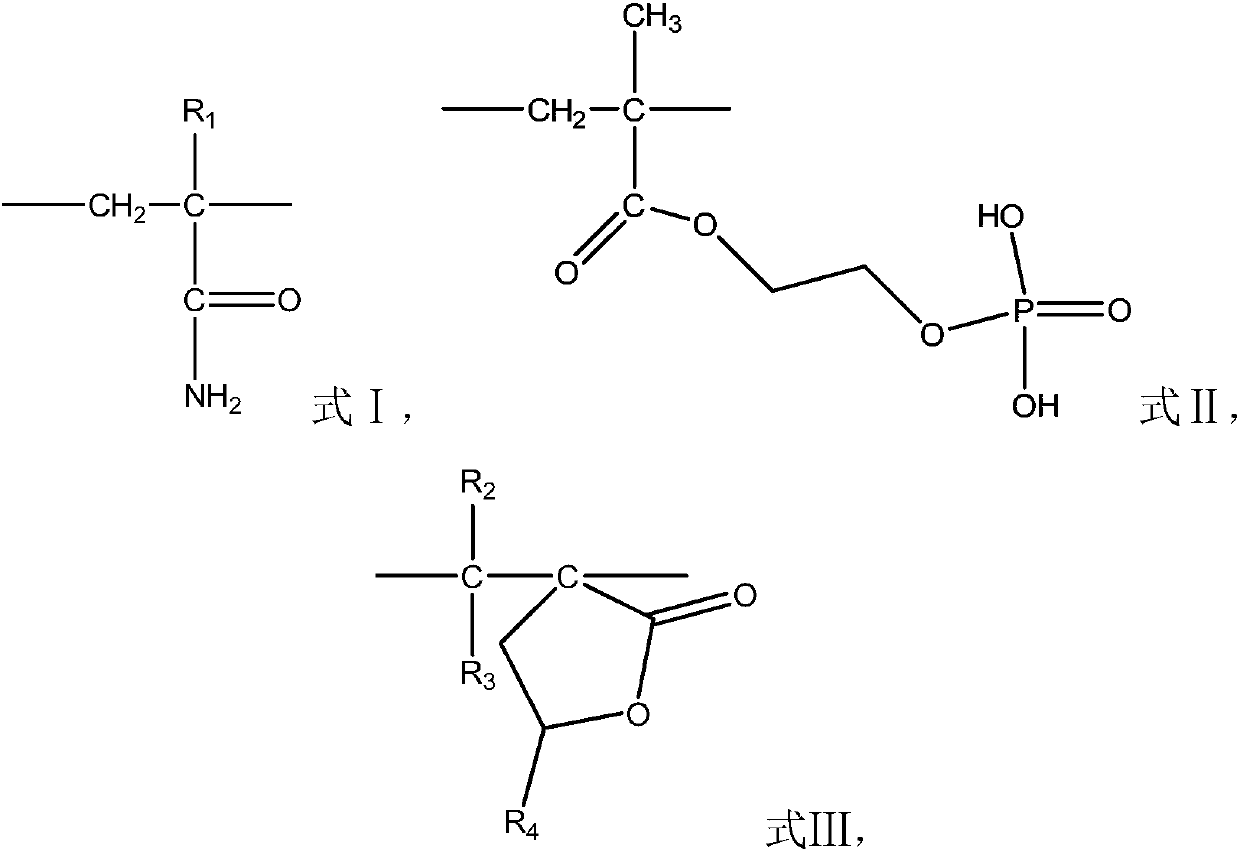

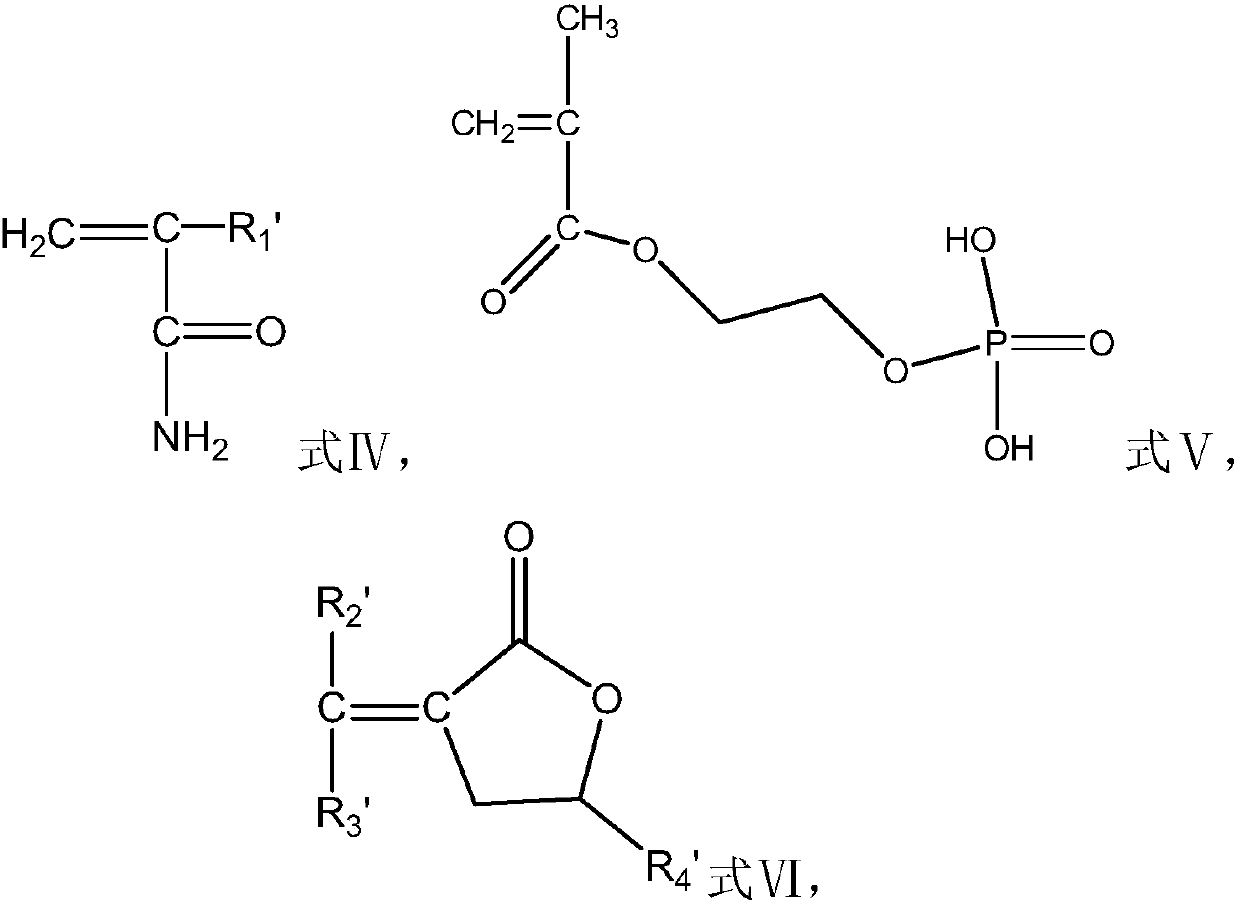

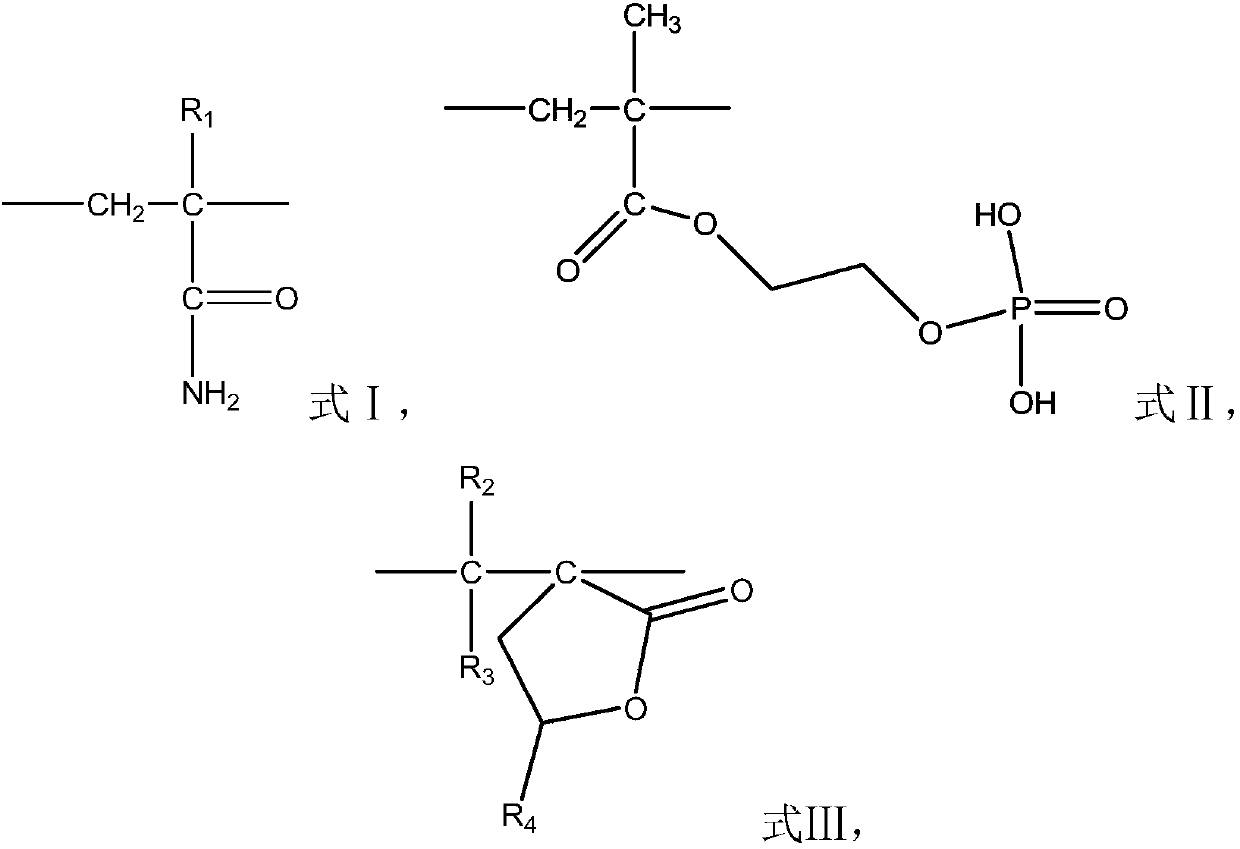

[0028] At the same time, the present invention also provides a method for preparing an acrylamide copolymer, the preparation method comprising the following steps: under the solution polymerization reaction conditions of olefins, in the presence of an initiator, the monomer mixture is polymerized in water , the monomer mixture contains monomer D having the structure shown in formula IV, monomer E having the structure shown in formula V and monomer F having the structure shown in formula VI, and the monomer D, the monomer The weight ratio of body E and said monomer F is 1:(0.01~0.65):(0.01~0.65),

[0029]

[0030] In Formula IV, R 1 ' is any one of H and C1-C4 alkyl; in formula VI, R 2 ', R 3 'are independently selected from any one of H and C1~C12 alkyl groups; R 4 ' is any one selected from H, C1-C12 alkyl groups, and C6-C12 alkyl groups. The C1-C4 alkyl group, the C1-C12 alkyl group, and the C6-C12 aryl group are the same as those described above, and will not be repe...

Embodiment 1

[0061] It is used to illustrate the acrylamide copolymer of the present invention and its preparation method.

[0062] The structure of the adopted α-methylene-γ-lactonate (commercially purchased from Aladdin Reagent Company, the same below) is as follows:

[0063]

[0064] The preparation method of acrylamide copolymer comprises:

[0065] Add 200g of acrylamide (AM), 25g of 2-hydroxyethyl methacrylate phosphate and 25g of the above-mentioned α-methylene-γ-lactonate and 1000g of de Ionized water; after the raw materials are dissolved, add sodium hydroxide to the aqueous solution to adjust the pH of the aqueous solution to 7.5; then pass nitrogen gas into the aqueous solution to remove oxygen for 30 minutes and then seal the beaker to form an inert atmosphere; then add 0.01 g of ammonium persulfate and 0.01 g of sodium bisulfite was used as a redox initiator system, and then reacted at normal pressure and constant temperature (controlled with frozen brine) for 7 hours to ob...

Embodiment 2

[0068] It is used to illustrate the acrylamide copolymer of the present invention and its preparation method.

[0069]The α-methylene-γ-lactonate used: the same as in Example 1.

[0070] The preparation method of acrylamide copolymer comprises:

[0071] At room temperature, under stirring conditions, add 225g of acrylamide (AM), 50g of 2-hydroxyethyl methacrylate phosphate and 12.5g of the above-mentioned α-methylene-γ-lactonate and 1000g of Deionized water; after the raw materials are dissolved, add sodium hydroxide to the aqueous solution to adjust the pH of the aqueous solution to 6.5; then pass nitrogen gas into the aqueous solution to remove oxygen for 30 minutes and then seal the beaker to form an inert atmosphere; then add 0.02 g of initiator 2 to the aqueous solution , 2'-Azobis(2-methylpropionamidine) hydrochloride (AIBA), and then react at normal pressure and 50°C constant temperature (water bath temperature control) for 4 hours to obtain a colloidal polymer solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com