Wood industry vegetable adhesive and preparation method thereof

An adhesive, an industrial technology, applied in the field of wood industry plant adhesives and its preparation, can solve the problems that the performance cannot meet the requirements of industrial use, etc., to solve storage stability, improve bonding strength and water resistance, improve water resistance and bonding intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

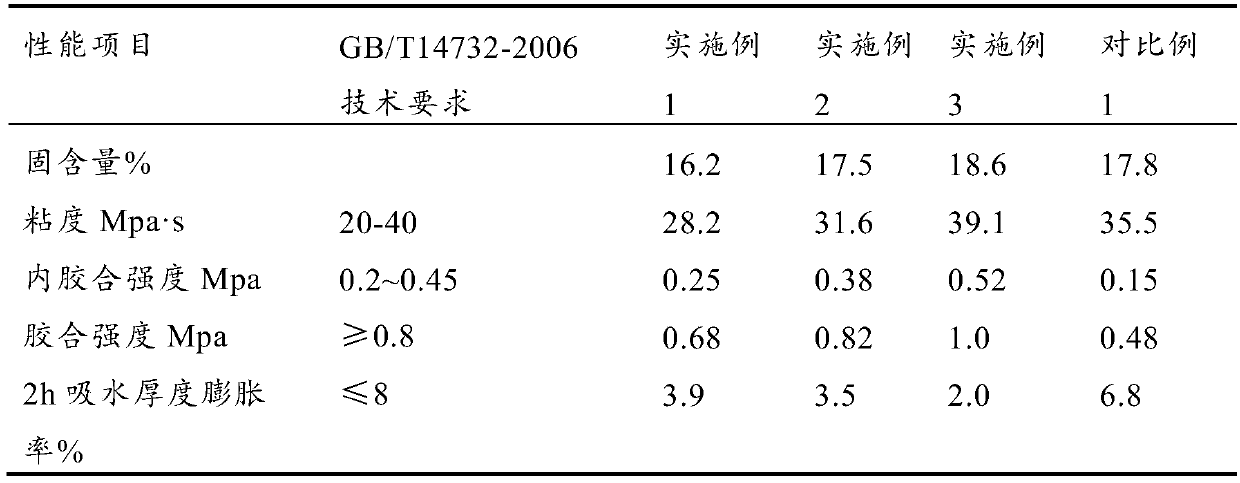

Examples

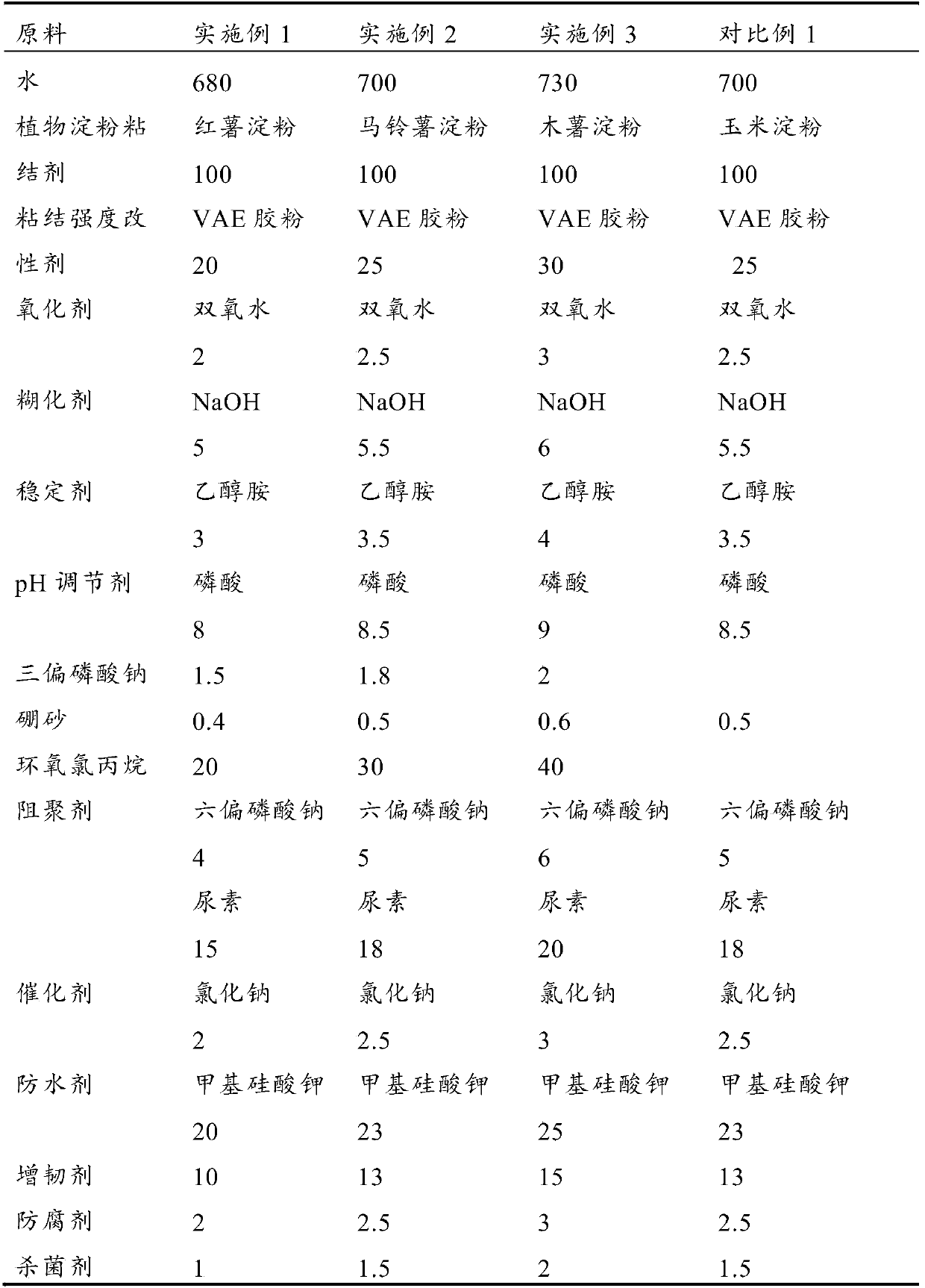

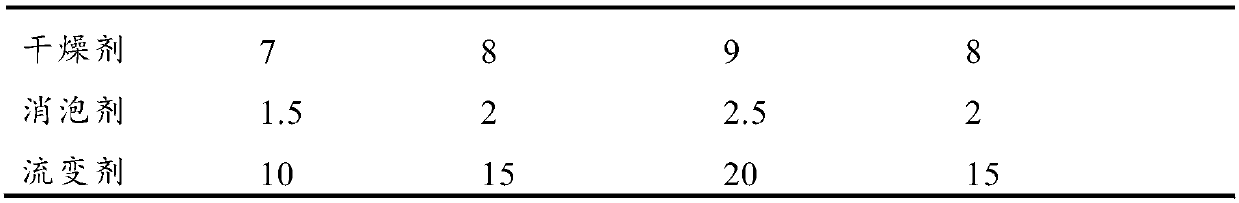

Embodiment 1~3 and comparative example 1

[0026] Embodiment 1~3 and comparative example 1 wood industry plant adhesive

[0027] The first preparation material is:

[0028] Prepare a solid content of 30% sodium hydroxide aqueous solution for subsequent use;

[0029] Preparation concentration is the phosphoric acid aqueous solution of 15% standby;

[0030] Prepare alum, ferrous sulfate and anhydrous calcium chloride 1:1:1 (weight ratio) and mix for subsequent use;

[0031] Prepare water: the (weight ratio) aqueous solution of borax=20:1 is standby;

[0032] Prepare a 30% aqueous urea solution, and then dissolve sodium hexametaphosphate into the 30% aqueous urea solution to prepare a polymerization inhibitor for future use.

[0033] a. Disperse the vegetable starch binder and the bond strength modifier in water under stirring at a rate of 200rpm; after the dispersion is uniform, add a stabilizer and mix uniformly; Butyl ester to suppress the bubbles generated under stirring, and continue to disperse for 10 to 15 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com