Perovskite thin-film solar cell employing cadmium sulfide as window material and preparation method of perovskite thin-film solar cell

A solar cell and perovskite technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problem of unadaptable photoelectric conversion efficiency, stability of perovskite solar cells, and restrictions on the industrialization of perovskite solar cells, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

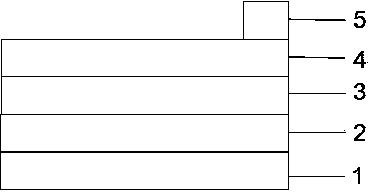

[0015] Embodiment 1: A kind of preparation method of the perovskite thin-film solar cell using cadmium sulfide as window material, according to the following steps:

[0016] First, the N-type cadmium sulfide film was deposited on the FTO conductive glass substrate by chemical vapor deposition; then, the P-type perovskite film was deposited on the N-type cadmium sulfide film by a one-step solution method; then, the P-type perovskite film was The P-type heavily doped graphene film is prepared by spin-coating on the film; finally, silver metal front and back electrodes are respectively deposited on the P-type heavily doped graphene film and the FTO conductive glass substrate by evaporation method, that is, the required for perovskite thin-film solar cells.

Embodiment 2

[0017] Embodiment two: first, utilize chemical vapor deposition method to deposit N-type cadmium sulfide film on ITO conductive glass substrate; Then, utilize two-step continuous deposition method to deposit P-type perovskite film on N-type cadmium sulfide film; Then, On the P-type perovskite film, the P-type heavily doped graphene film was deposited by electrophoresis; finally, on the P-type heavily doped graphene film and the ITO conductive glass substrate, the aluminum metal front and the The back electrode is to make the required perovskite thin film solar cell.

Embodiment 3

[0018] Embodiment three: first, utilize sol-gel method to prepare N-type cadmium sulfide film on ZTO conductive glass substrate; Then, utilize solution-vapor phase precipitation method to prepare P-type perovskite film on N-type cadmium sulfide film; Then , on the P-type perovskite film by chemical vapor deposition method to prepare P-type heavily doped graphene film; finally, on the P-type heavily doped graphene film and ZTO conductive glass substrate by screen printing The metal front and back electrodes are used to make the required perovskite thin film solar cells.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com