Preparation method of bifunctional catalysis carbon material used for zinc air battery

A technology of zinc-air battery and functional catalytic carbon, which is applied in the direction of hybrid battery, battery electrode, fuel cell half-cell and secondary battery-type half-cell, etc., which can solve the difficult to meet application requirements and realize simultaneous catalysis and other issues, to achieve the effects of easy implementation, ensuring dual-functional catalytic activity, and reducing industrialization costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

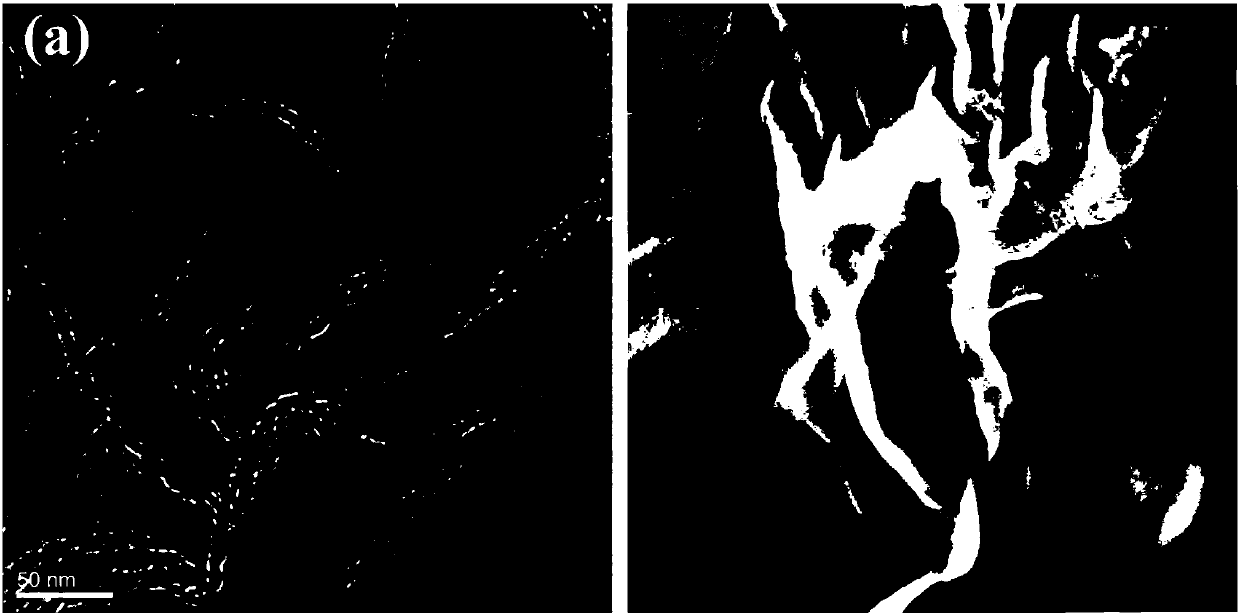

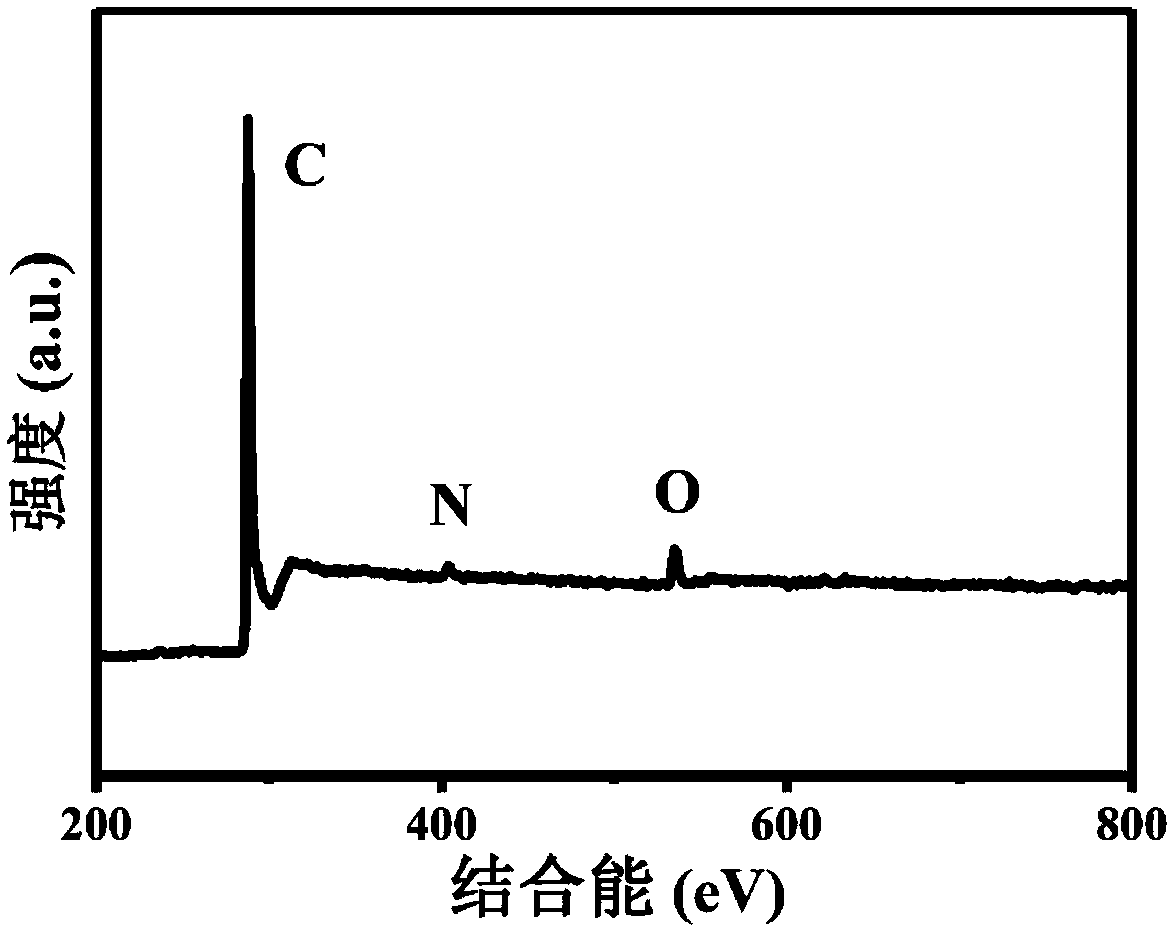

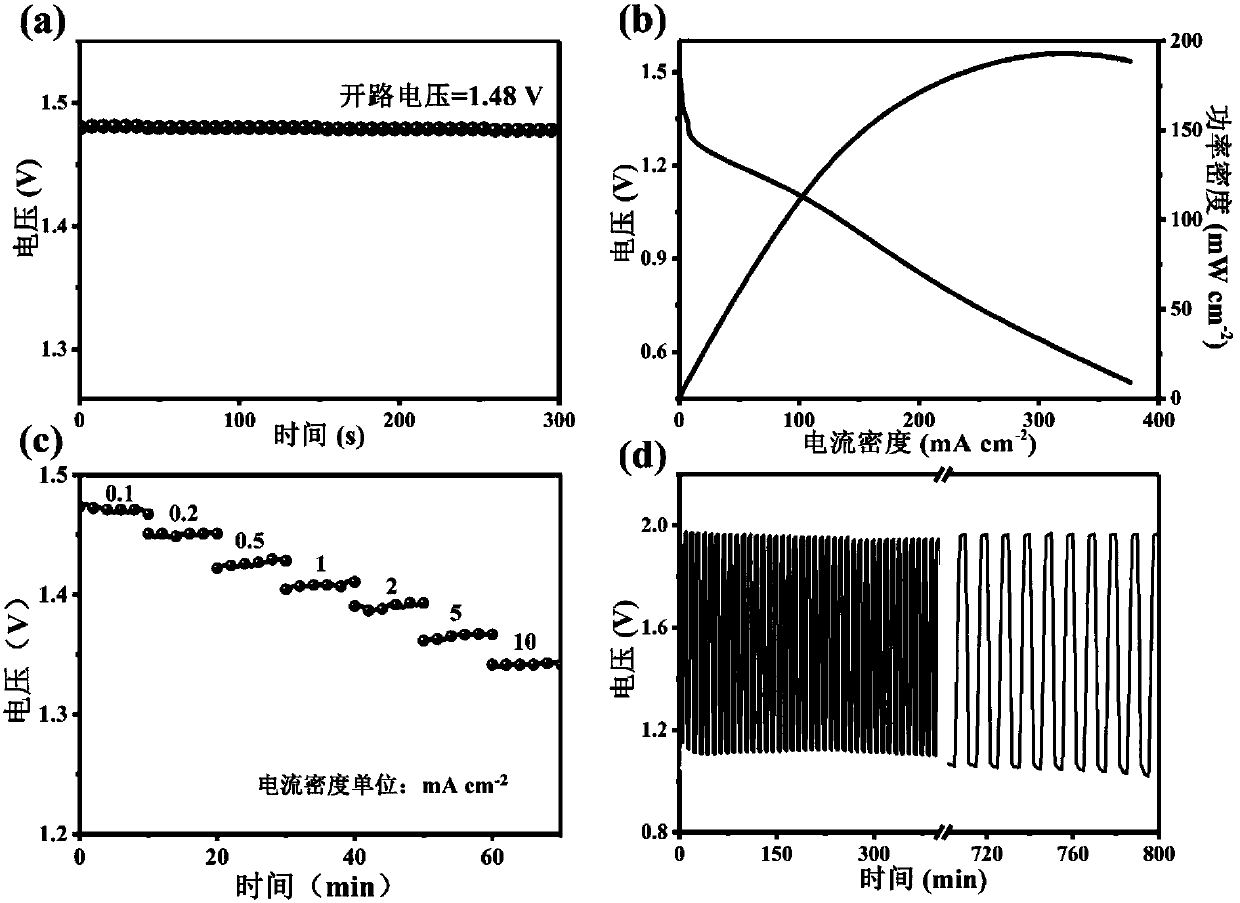

[0019] The preparation method of bifunctional catalytic carbon material for zinc-air battery of the present invention is characterized in that it comprises the following steps: (a) making pyrrole monomer in deionized water in FeCl 2 and H 2 o 2 Under the action of reacting to form a complex, followed by drying to obtain a brown product; (b) dissolving the brown product in deionized water, adding NaCl and then freeze-drying; (c) placing the freeze-dried product in step (b) In a tube furnace, annealing is carried out under the protection of an inert gas; washed successively with deionized water and alcohol, and vacuum-dried; (d) taking the product of step (c) and placing it in hydrochloric acid for stirring, centrifuging, and finally using deionized Washing with water and alcohol in sequence, and then vacuum drying to obtain oxygen and nitrogen co-doped carbon nanosheets; the pyrrole monomer, FeCl 2 、H 2 o 2 The ratio with NaCl is 1-3ml: 0.3-0.7g: 15-35ml: 5-10g. A specific...

Embodiment 1

[0023] This embodiment provides a method for preparing a bifunctional catalytic carbon material for a zinc-air battery, which comprises the following steps:

[0024] (a) Take 100ml of deionized water, add 2ml of pyrrole monomer to it, and ultrasonically treat it for 30 minutes to make it uniformly dispersed to form a suspension; add 0.4g of FeCl to the uniformly dispersed suspension of pyrrole 2 , drop 30ml H 2 o 2 , fully stirred and continued to react for 24 hours to form a complex, and after drying, a brown product was obtained;

[0025] (b) Disperse the brown product obtained above in deionized water, add 8g NaCl, stir for more than 12 hours, and then lyophilize;

[0026] (c) placing the freeze-dried product in a tube furnace, annealing at 1000° C. for 2 hours under the protection of Ar gas, and the gas flow rate is 200 sccm; fully washing the annealed material successively with a large amount of deionized water and alcohol, vacuum drying;

[0027] (d) Take the dried m...

Embodiment 2

[0030] This embodiment provides a method for preparing a bifunctional catalytic carbon material for a zinc-air battery, which comprises the following steps:

[0031] (a) Take 100ml of deionized water, add 3ml of pyrrole monomer to it, and ultrasonically treat it for 30 minutes to make it uniformly dispersed; add 0.5g of FeCl to the uniformly dispersed suspension of pyrrole 2 , slowly drop into 35ml H 2 o 2 , fully stirred and continued to react for 24 hours to form a complex; dry after drying to obtain a brown product;

[0032] (b) Disperse the brown product obtained above in deionized water, add 10g NaCl, stir for more than 12 hours, and then freeze-dry;

[0033](c) Place the lyophilized product in a tube furnace, anneal at 600°C for 2 hours under the protection of Ar gas, and the gas flow rate is 200 sccm; wash the annealed material with deionized water and alcohol in sequence, and dry it in vacuum ;

[0034] (d) Take an appropriate amount of dried material and place it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com