Phenol-amine alternately-assembled composite nano-filtration film and preparation method thereof

A composite nanofiltration membrane and phenolic amine technology, which is applied in the field of membrane separation, can solve the problems of affecting the performance of the separation membrane, the weak binding force between the separation membrane and the porous base membrane, and the number of separation membranes, so as to achieve regular arrangement, improve stability, and operate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Take 1g of tannic acid and dissolve it in the prepared N-N bishydroxyethylglycine (Bicine) buffer solution at a concentration of 1g / L, adjust the pH to 4-5 with 0.1M NaOH solution; then take 1g of polyethylene Imine (weight-average molecular weight Mw=600Da) was dissolved in deionized water at a concentration of 1 g / L, and the pH was adjusted to 8-9 with 0.1 M HCl solution.

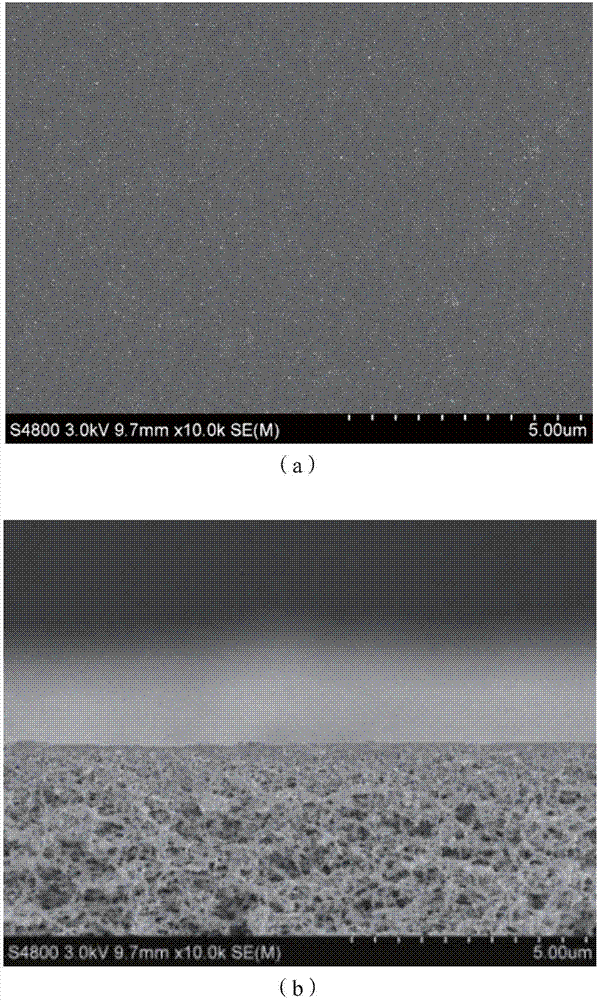

[0058] Use the polysulfone ultrafiltration membrane (with a molecular weight cut-off of 5-100,000 Da) as the porous polymer support membrane, firstly immerse it in the positively charged polyethyleneimine solution, and fully infiltrate it for 5 minutes; after taking it out, wash it with deionized water After rinsing and drying, immerse again in negatively charged tannic acid solution for 5 minutes of reaction (Michael addition and Schiff base reaction and subsequent polymerization reaction). After the end, take out the polysulfone ultrafiltration membrane, rinse it with deionized water again, put i...

Embodiment 2~4

[0061] The concentrations of the polyamines in Examples 2-4 are 2g / L, 3g / L and 4g / L respectively, and other conditions are the same as in Example 1.

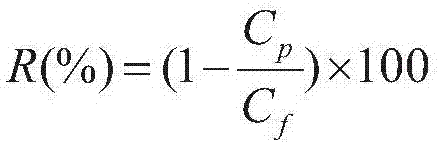

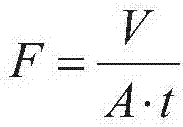

[0062] The water flux and desalination rate of the composite nanofiltration membranes prepared in Examples 1-4 were tested, and the results are shown in Table 1.

[0063] The water flux and MgCl of the composite nanofiltration membrane prepared in table 1 embodiment 1~4 2 Salt rejection rate

[0064] test

Embodiment 5

[0075] Take 1g of dopamine and dissolve it in the prepared Tris-HCl buffer solution at a concentration of 1g / L, adjust the pH to 4-5 with 0.1M NaOH solution; then take 2g The o-phenylenediamine was dissolved in deionized water at a concentration of 2 g / L, and the pH was adjusted to 8-9 with 0.1 M HCl solution.

[0076] The polyacrylonitrile ultrafiltration membrane (molecular weight cut-off of 100,000-200,000 Da) is used as a porous polymer support membrane (the membrane is first pretreated with alkali solution), first immersed in o-phenylenediamine solution, and fully infiltrated after 10 minutes Rinse with deionized water after taking it out, immerse in the dopamine solution again after drying and carry out the reaction for 10min (Michael addition and Schiff base reaction and subsequent polymerization reaction). After the end, take out the polyacrylonitrile ultrafiltration membrane, rinse it with deionized water again, put it in a vacuum drying oven after drying, and activat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com