Method for preparing chitosan/multilayer hybrid nanoparticle antibacterial preservative film

A technology of hybrid nanoparticle and chitosan, which is applied in the field of food packaging to achieve excellent antibacterial and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

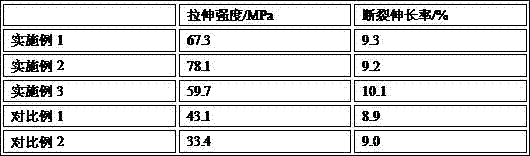

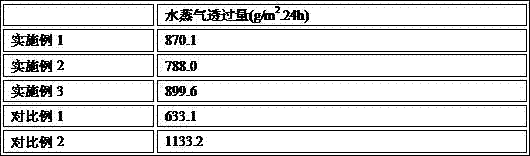

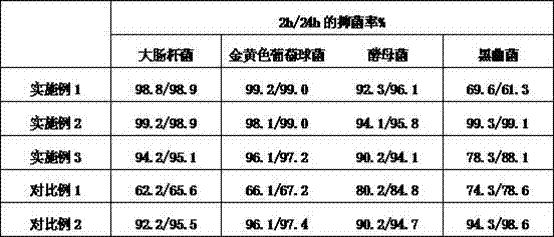

Examples

Embodiment 1

[0023] Preparation of organic-inorganic hybrid nanomaterials:

[0024] 1) Disperse 3.0g of nanometer cerium oxide and 1.3g of phosphotungstic acid in 100ml of tetrahydrofuran (the volume ratio of tetrahydrofuran to water is 1:2), and ultrasonically disperse for 30 minutes to obtain a dispersion;

[0025] 2) Heat the dispersion to 55°C, then add phosphoric acid dropwise to adjust the pH to 3.6, then add 2.4g of 2,2'-biimidazole, conduct a hydrothermal reaction at 60°C for 24 hours, then desolvate under reduced pressure at 45°C to obtain a gray-yellow powder , the gray-yellow powder was placed in n-heptane at 50° C. for 2 h, then filtered, aged at 80° C. for 6 h, and pulverized to obtain organic-inorganic hybrid nanomaterials.

[0026] Prepare chitosan / multilayer hybrid nanoparticle antibacterial preservative film, comprising the following steps:

[0027] 1) Preparation of chitosan solution: Disperse chitosan in an aqueous solution of acetic acid, then add polydiallyldimethylam...

Embodiment 2

[0032] The preparation method of the organic-inorganic hybrid nanomaterial is the same as that in Example 1.

[0033] Prepare chitosan / multilayer hybrid nanoparticle antibacterial preservative film, comprising the following steps:

[0034] 1) Preparation of chitosan solution: Disperse chitosan in an aqueous solution of acetic acid, then add polydiallyldimethylammonium chloride, heat and stir to dissolve to obtain chitosan solution;

[0035] 2) Add organic-inorganic hybrid nanomaterials to the chitosan solution, and disperse evenly (the organic-inorganic hybrid nanomaterials can be evenly dispersed at a speed of 200-300rpm, and there is no accumulation of nanoparticle materials after the stirring is stopped. ) after defoaming, then place the dispersion in a glass tank, cast and dry the film-forming precursor;

[0036] 3) Ultrasonicate the membrane precursor at low temperature for 3-5 minutes in a phosphate buffer solution with weakly acidic pH (pH=6.5-6.8), wash the membrane s...

Embodiment 3

[0039] The preparation method of the organic-inorganic hybrid nanomaterial is the same as that in Example 1.

[0040] Prepare chitosan / multilayer hybrid nanoparticle antibacterial preservative film, comprising the following steps:

[0041] 1) Preparation of chitosan solution: Disperse chitosan in an aqueous solution of acetic acid, then add polydiallyldimethylammonium chloride, heat and stir to dissolve to obtain chitosan solution;

[0042] 2) Add organic-inorganic hybrid nanomaterials to the chitosan solution, disperse evenly and defoam, then place the dispersion in a glass tank, cast and dry the film-forming precursor;

[0043] 3) Ultrasonicate the membrane precursor at low temperature for 3-5 minutes in a phosphate buffer solution with weakly acidic pH (pH=6.5-6.8), wash the membrane surface with phosphate buffer salt with purified water, then dry it and demold it to obtain chitosan Sugar / hybrid nanoparticle antibacterial cling film;

[0044] The concentration of chitosan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com