Antistatic shoe material and preparation method thereof

An antistatic and shoe material technology, applied in the field of shoe material manufacturing materials, can solve the problems of decreased antistatic performance, inability to satisfy the uniformity of sole wear resistance, high tensile performance and antistatic performance, etc., and achieve mechanical performance growth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

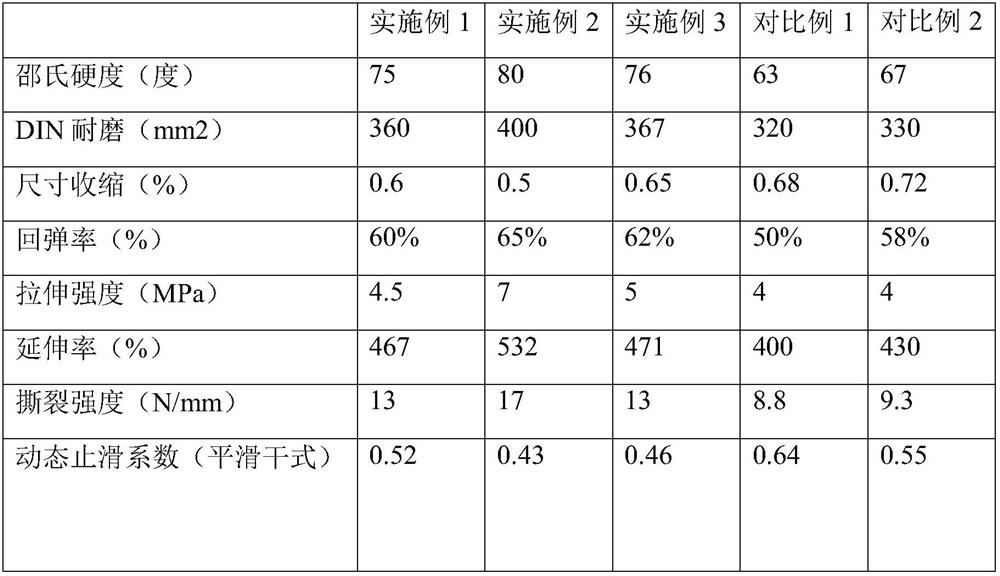

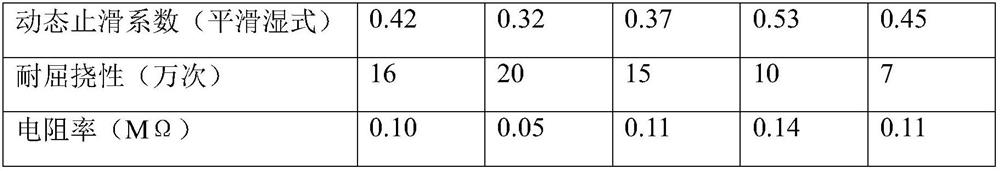

Embodiment 1

[0034] An antistatic shoe material comprises the following components in parts by weight:

[0035] 50 parts of ethylene-vinyl acetate copolymer, 50 parts of recycled polyethylene, 4 parts of foaming agent, 0.1 part of crosslinking agent, 0.1 part of stearic acid, 0.1 part of zinc oxide, 10 parts of conductive carbon black, 0.3 parts of accelerator, white 20 parts of carbon black. Above-mentioned foaming agent is selected sodium bicarbonate. The above-mentioned crosslinking agent is composed of a mixture with a weight ratio of di-tert-butylperoxycumene:sulfur=3:1.5. The above accelerator is composed of a mixture with a weight ratio of chromium oxide green: di-o-tolylguanidine = 3:1. The above-mentioned dispersant is composed of a mixture with a weight ratio of oxidized polyethylene wax:copper stearate=5:3. The above-mentioned conductive carbon black is processed, and the processing process is: place 10 parts of the weighed conductive carbon black in 40% hydrogen peroxide for...

Embodiment 2

[0044] An antistatic shoe material comprises the following components in parts by weight:

[0045]60 parts of ethylene-vinyl acetate copolymer, 60 parts of recycled polyethylene, 5 parts of foaming agent, 0.5 parts of crosslinking agent, 0.5 parts of stearic acid, 0.5 parts of zinc oxide, 12 parts of conductive carbon black, 0.5 parts of accelerator, white 22 parts of carbon black. Above-mentioned foaming agent is selected sodium bicarbonate. The above-mentioned crosslinking agent is composed of a mixture with a weight ratio of di-tert-butylperoxycumene:sulfur=3:1.5. The above accelerator is composed of a mixture with a weight ratio of chromium oxide green: di-o-tolylguanidine = 3:1. The above-mentioned dispersant is composed of a mixture with a weight ratio of oxidized polyethylene wax:copper stearate=5:3. The above-mentioned conductive carbon black is processed, and the processing process is: place 12 parts of the weighed conductive carbon black in 40% hydrogen peroxide f...

Embodiment 3

[0054] An antistatic shoe material comprises the following components in parts by weight:

[0055] 70 parts of ethylene-vinyl acetate copolymer, 70 parts of recycled polyethylene, 6 parts of foaming agent, 1 part of crosslinking agent, 1 part of stearic acid, 1 part of zinc oxide, 15 parts of conductive carbon black, 0.8 parts of accelerator, white 25 parts of carbon black. Above-mentioned foaming agent is selected sodium bicarbonate. The above-mentioned crosslinking agent is composed of a mixture with a weight ratio of di-tert-butylperoxycumene:sulfur=3:1.5. The above accelerator is composed of a mixture with a weight ratio of chromium oxide green: di-o-tolylguanidine = 3:1. The above-mentioned dispersant is composed of a mixture with a weight ratio of oxidized polyethylene wax:copper stearate=5:3. The above-mentioned conductive carbon black is processed, and the treatment process is: place 15 parts of the weighed conductive carbon black in 40% hydrogen peroxide for 3 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com