Whisker reinforced polyether ketone ketone composite material and preparation method thereof

A technology of polyether ketone ketone and composite materials, applied in the field of composite materials, can solve the problems of insufficient metal index, mold wear, poor material surface finish, etc., achieve excellent wear resistance, reduce power consumption and noise, reduce weight and cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

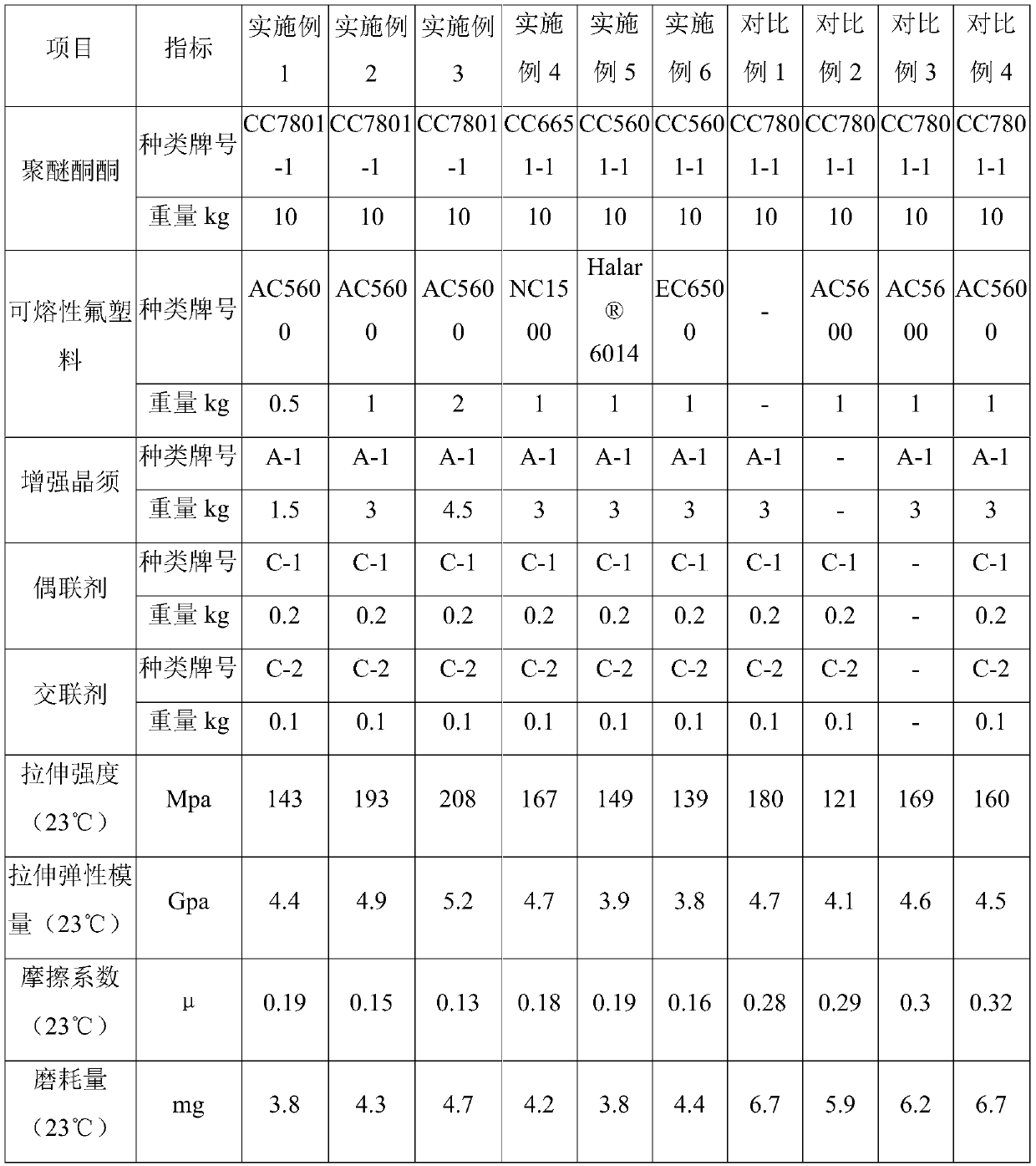

Embodiment 1~3

[0043] According to the ratio shown in Table 1, add the ingredients shown in Table 1 into the high-speed mixer and mix for 5 minutes, then pack the mixed material A into bags for later use; integrate the above-mentioned mixed material A with a fluidized bed jet mill at high speed Modified crushing and mixing treatment, the frequency setting of the feeder and the induced draft fan are 40 and 50 Hz respectively, the frequency setting range of the classifier is 10 Hz, the air supply pressure is 0.7 MPa, and the fine powder with a particle size of less than 150 μm is selected to be bagged for later use. Mixture B; first use a coupling agent to surface-treat the inorganic whiskers, and then mix the treated inorganic whiskers with the above-mentioned mixture B through a high-speed mixer to obtain mixture C; use hot air circulation to mix C Dry heat treatment in the oven at 240°C for 4 hours; add the above dry heat-treated mixture C in batches into the mold cavity of the hot press for...

Embodiment 4~6

[0045] Since the grades of the selected polyetherketoneketone resin base materials are CC6651-1 and CC5601-1, the relevant processing temperatures are respectively 25°C and 40°C lower than those in Examples 1 to 3. In addition, according to the above-mentioned Example 1 ~3 The same method, after the integrated pulverization and mixing treatment, then hot press molding. The strength, wear resistance and hardness of each sample were measured, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com