Flexible heat-conducting gasket and preparation method thereof

A thermal pad, flexible technology, applied in the field of potting glue, to achieve the effect of convenient use, good bonding, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

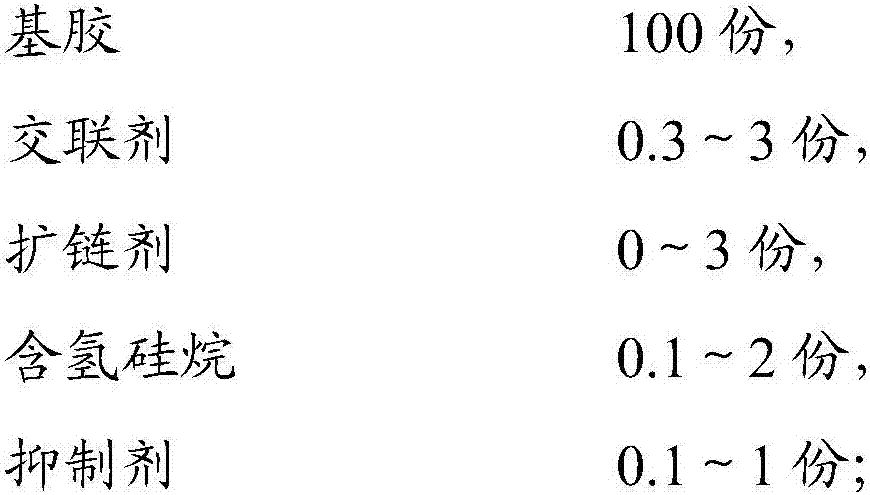

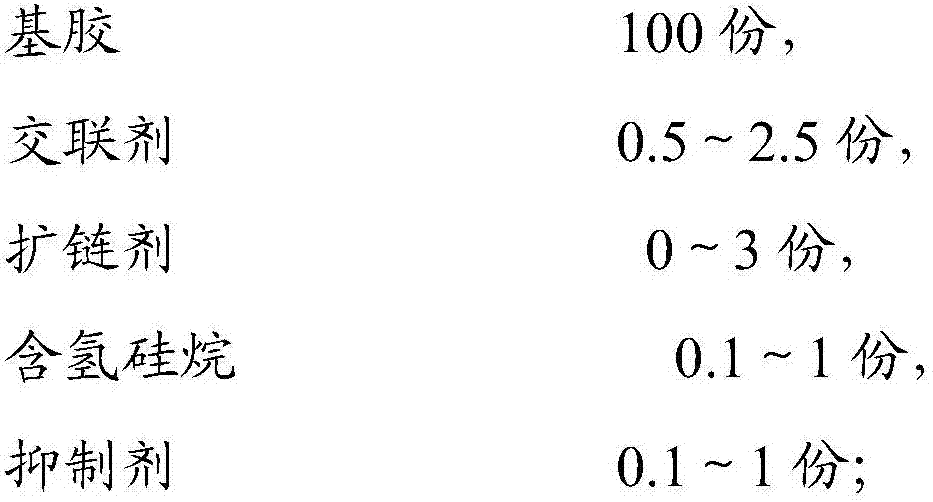

Method used

Image

Examples

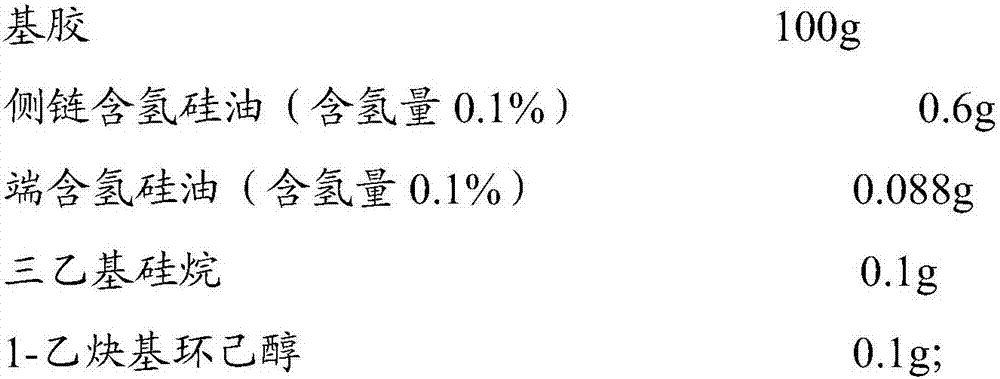

Embodiment 1

[0069] (1) Preparation of base glue: get 100 parts by weight of vinyl silicone oil (viscosity is 2000mPa·S, vinyl content is 0.22%) and put into kneader, add alumina filler (median particle size 25um) 900 weight in batches Knead at room temperature for 2 hours; raise the temperature to 150°C, and evacuate until the degree of vacuum reaches -0.1MPa, continue kneading for 3 hours, and obtain the base rubber after cooling.

[0070] (2) Preparation of hydrosilane: in a clean and dry reaction flask, add 64.5g ethyl chloride, 24g magnesium powder and 1g iodine initiator, carry out Grignard reaction in a mixed solution of 10mL tetrahydrofuran and 120mL xylene, Prepare the Grignard reagent at 35°C, then control the temperature at 10°C, add 44.7g of trichlorosilane, and raise the temperature to about 75°C for condensation reaction. After reacting for 6 hours, cool down to room temperature, and add the obtained reaction solution dropwise to ice water In the mixture, let stand to separat...

Embodiment 2

[0083] (1) Preparation of base glue: get 100 parts by weight of vinyl silicone oil (viscosity is 1000mPa·S, vinyl content is 0.3%) and put into kneader, add alumina filler (median particle size 25um) 900 weight in batches Knead at room temperature for 2 hours; raise the temperature to 150°C, and evacuate until the degree of vacuum reaches -0.1MPa, continue kneading for 2 hours, and obtain the base rubber after cooling.

[0084] (2) Preparation of hydrosilane: In a clean and dry reaction flask, add 78.5g of 2-chloropropane, 24g of magnesium powder and 1g of initiator iodine, and carry out a Grignard reaction in a mixed solution of 10mL of tetrahydrofuran and 150mL of xylene. Prepare the Grignard reagent at 145°C, then control the temperature at 10°C, add 38.7g of trichlorosilane, and the temperature rises to about 75°C for condensation reaction. After reacting for 8 hours, cool down to normal temperature, and add the resulting reaction solution dropwise to ice In the water mixt...

Embodiment 3

[0097] (1) Preparation of base glue: get 100 parts by weight of vinyl silicone oil (viscosity is 300mPa S, vinyl content is 0.54%) and put into kneader, add alumina filler (median particle size 25um) 900 weight in batches Knead at room temperature for 2 hours; raise the temperature to 150°C, and evacuate until the degree of vacuum reaches -0.1MPa, continue kneading for 3 hours, and obtain the base rubber after cooling.

[0098] (2) Preparation of hydrosilane: In a clean and dry reaction flask, add 92.5g of tert-chlorobutane, 24g of magnesium powder and 1g of iodine as an initiator, and perform a Grignard reaction in a mixed solution of 10mL of tetrahydrofuran and 160mL of xylene , make Grignard reagent at 75°C, then control the temperature at 10°C, add 34g of trichlorosilane, the temperature rises to about 75°C for condensation reaction, after reacting for 8 hours, cool down to normal temperature, and add the obtained reaction liquid dropwise to ice In the water mixture, let s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com