Martensite-ferrite-austenite complex-phase abrasion-resistant steel plate with low yield ratio and manufacturing method thereof

A low-yield-ratio, wear-resistant steel plate technology, applied in the field of low-alloyed steel manufacturing, can solve the problems of low-temperature impact toughness of steel plates, difficult to guarantee cold-formability, poor low-temperature toughness and formability of steel plates, etc., and achieve excellent low-temperature impact toughness. And the effect of cold bending formability, lower yield ratio, and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

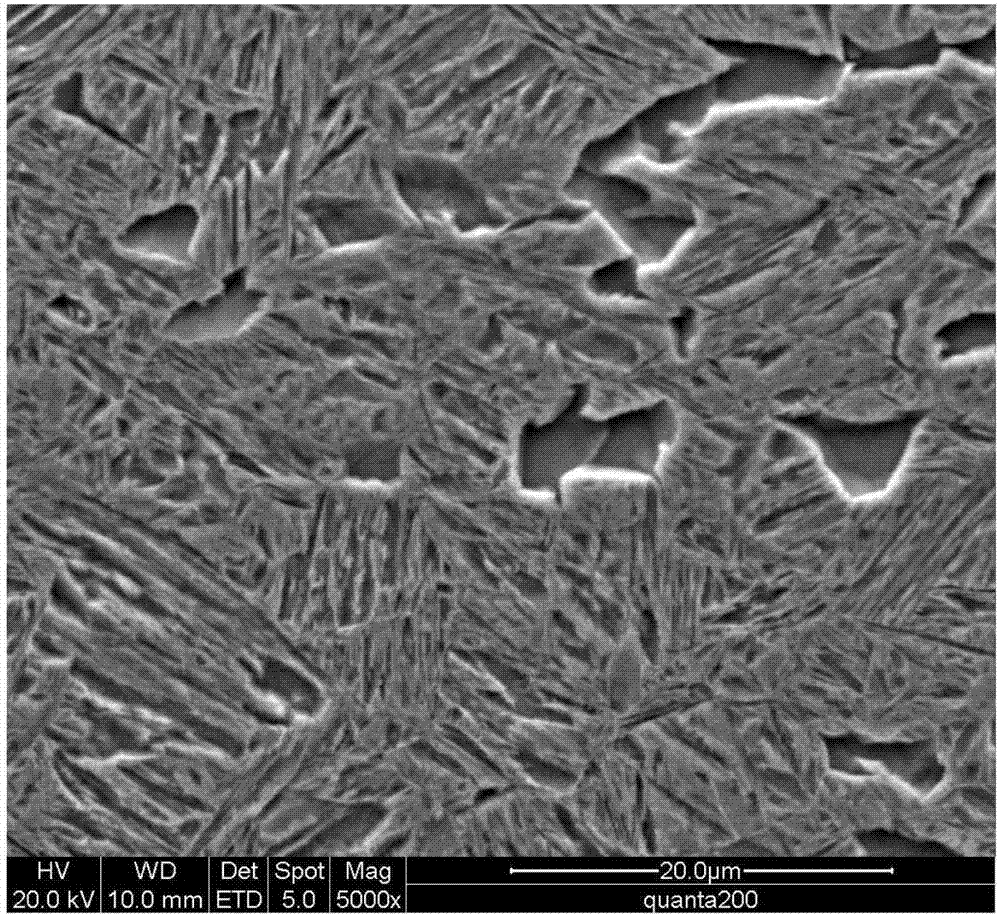

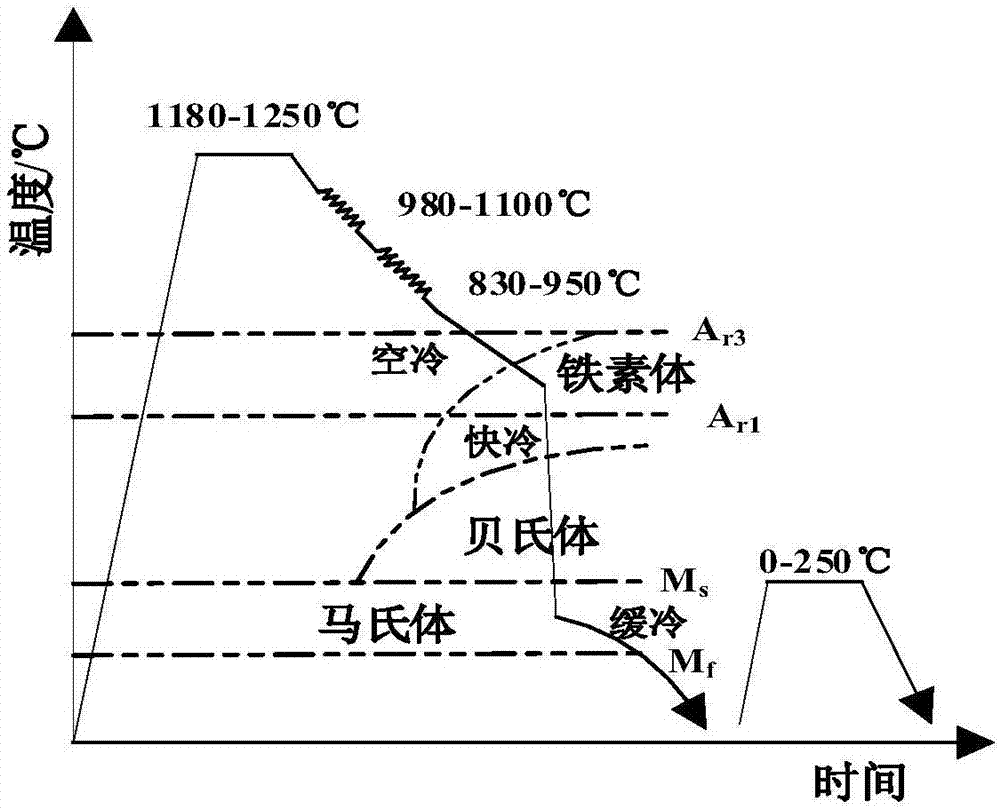

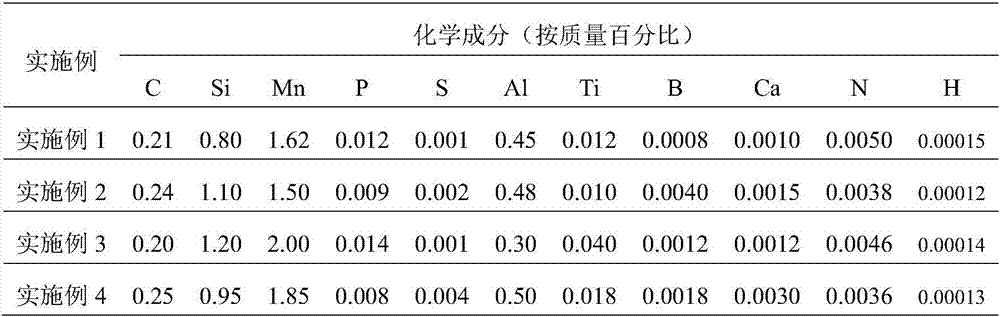

[0033]The chemical composition of embodiment 1 is as shown in table 1. According to the chemical composition of Example 1 in Table 1, the electric furnace or converter is smelted, and after refining, it is poured into a continuous casting slab, and the continuous casting slab is heated to 1200 ° C, kept for 3 hours, and then the medium and thick steel plate rolling mill is used for controlled rolling and control Cooling process, in which the rough rolling pass is 4 passes, the rough rolling finish rolling temperature is 1020°C; the finish rolling pass is 5 passes, the finish rolling finish rolling temperature is 840°C; the steel plate rolling thickness is 20mm; Air cooling to 780°C, then rapid cooling to 380°C, and finally stacking and slow cooling to room temperature; tempering heat treatment is carried out on the rolled steel plates, wherein the tempering temperature is 220°C, and the tempering holding time is 48 minutes.

[0034] The mechanical properties of the finished st...

Embodiment 2

[0037] The chemical composition of embodiment 2 is as shown in table 1. According to the chemical composition of Example 2 in Table 1, the electric furnace or converter is smelted, and after refining, it is poured into continuous casting slabs, and the continuous casting slabs are heated to 1180 ° C and kept for 3.5 hours, and then the hot continuous rolling mill is used for controlled rolling and control. Cooling process, the rolling process is: rough rolling 7 times, rolling the steel billet into a 30mm intermediate billet, and then rolling it into a 6mm finished steel coil through a 7-stand rolling mill. The final rolling temperature is 880°C. Controlled cooling, and then coiled into steel coils, the controlled cooling process is: first air-cooled to 770°C, then rapidly cooled to about 350°C, and finally coiled and slowly cooled to room temperature; the rolled steel coils are cooled in a bell annealing furnace Low temperature tempering heat treatment, wherein the tempering ...

Embodiment 3

[0041] The chemical composition of embodiment 3 is as shown in table 1. Carry out electric furnace or converter smelting according to the chemical composition of Example 3 in Table 1, pour into continuous casting slab or steel ingot after refining, the continuous casting slab or steel ingot is heated to 1250 ℃, keep warm for 2 hours, and then use hot continuous rolling mill to control Rolling and controlled cooling process, the rolling process is: rough rolling 5 times, rolling the billet into a 50mm intermediate billet, and then rolling it into a 10mm finished steel coil through a 7-stand rolling mill, where the final rolling temperature is 880°C , After controlled cooling after rolling, and then coiled into steel coils, the controlled cooling process is: first air-cooled to 790°C, then rapidly cooled to about 380°C, and finally coiled and slowly cooled to room temperature; Low-temperature tempering heat treatment is carried out in the annealing furnace, wherein the tempering...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com