Method for preparing modified aramid fiber/graphene reinforcement

A technology for modifying aramid fibers and aramid fibers, applied in the field of materials, can solve the problems of less surface active functional groups and poor interface bonding ability, and achieve the effects of improving performance, improving roughness, and improving interface bonding ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention: prepare the method for modified aramid fiber / graphene reinforcement, comprise the steps:

[0020] 1) Modified aramid fiber by ultraviolet radiation: place the aramid fiber in a beaker, add acetone to soak, in order to prevent the volatilization of acetone, immediately seal the mouth of the beaker with plastic wrap; put the sealed beaker in an ultrasonic cleaner After cleaning for 4 hours in the middle, remove the residual organic impurities on the surface of the aramid fiber produced, put it in a drying oven to dry, and then place the dried aramid fiber at a distance of 15cm from the ultraviolet lamp and modify it with ultraviolet light for 10 minutes. Then cut the aramid fibers after irradiation modification into short fibers of 5-10 mm to obtain ultraviolet radiation modified aramid fibers;

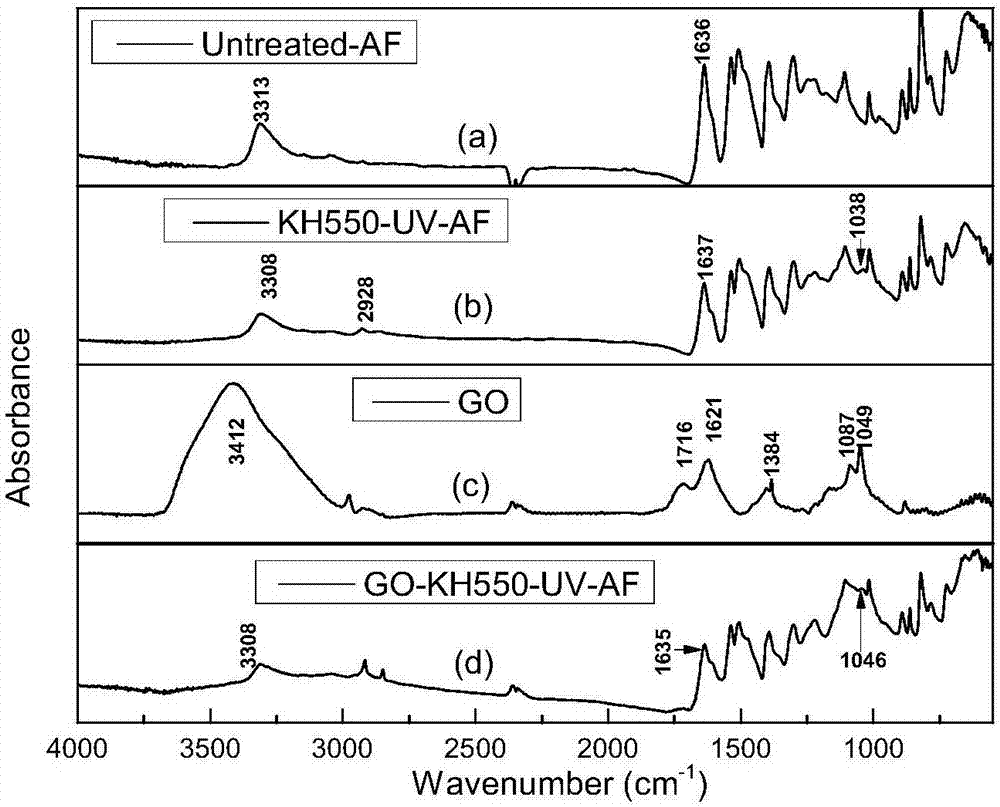

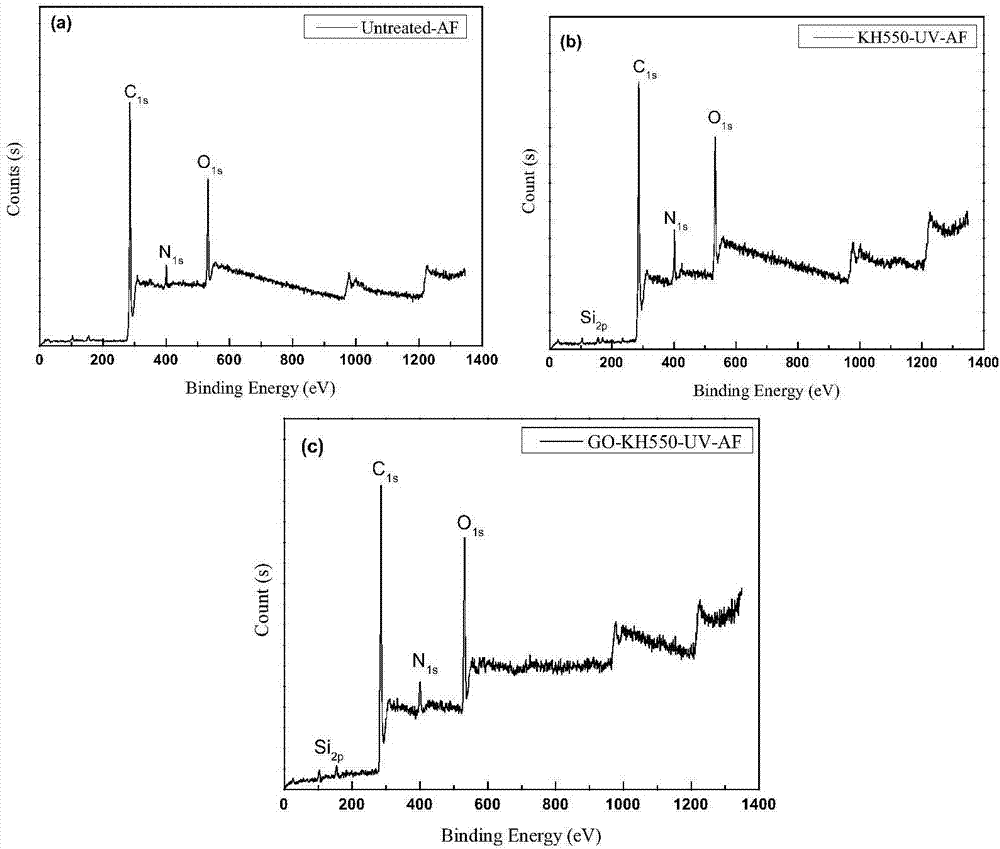

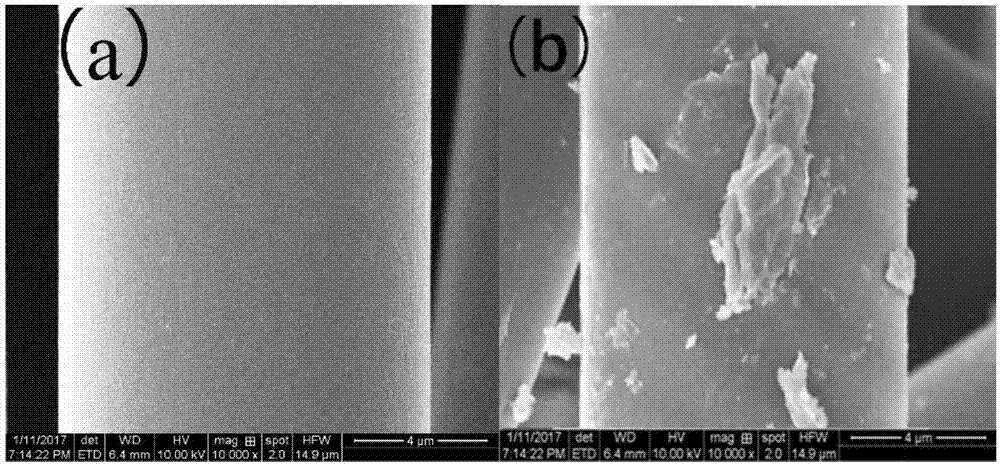

[0021] 2) KH550 grafted modified aramid fiber: configure KH550 ethanol solution with a mass fraction of 6%, and ultrasonically oscillate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com