Defluorination method of fluorine-containing hydrochloric acid

A technology of fluorine-containing hydrochloric acid and hydrochloric acid, which is applied in separation methods, chemical instruments and methods, halogen/halogen acid, etc., can solve the problems of inability to meet use requirements, affect the quality of hydrochloric acid, unavoidable, etc., and improve the efficiency of fluorine removal and regeneration. , The effect of good quality hydrochloric acid and convenient regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 200g of fluorine-containing hydrochloric acid (fluorine content 59.8ppm) into a fluoride bottle, add 1.0g of macroporous silica gel saturated with water absorption in the air, separate the silica gel after oscillating in a constant temperature oscillator at 30°C for 2 hours, and measure the fluorine content of the filtrate. The content is 15.5ppm. The separated silica gel was blotted dry with filter paper and put into a fluorinated bottle, then added 50.0 g of industrial water and oscillated in a constant temperature oscillator at 30°C for 1 hour to separate the silica gel. The fluorine content of the filtrate was determined to be 150.2 ppm.

Embodiment 2

[0032] Weigh 1.0g of macroporous silica gel saturated with water absorption in the air into a fluorinated bottle, add 20g of 2% NaOH aqueous solution, shake in a constant temperature oscillator at 30°C in a water bath for 1 hour, separate the silica gel, and then wash with deionized water to the center Dry it with filter paper and put it into a fluoride bottle, add 200g of fluorine-containing hydrochloric acid (fluorine content 59.8ppm) into the fluoride bottle, shake in a constant temperature oscillator at 30°C for 2 hours, separate the silica gel, and measure the fluorine content of the filtrate It is 7.2ppm. The separated silica gel was blotted dry with filter paper and put into a fluoride bottle, then added 50.0 g of deionized water and oscillated in a constant temperature oscillator at 30°C for 1 hour to separate the silica gel. The fluorine content of the filtrate was determined to be 183.3 ppm.

Embodiment 3

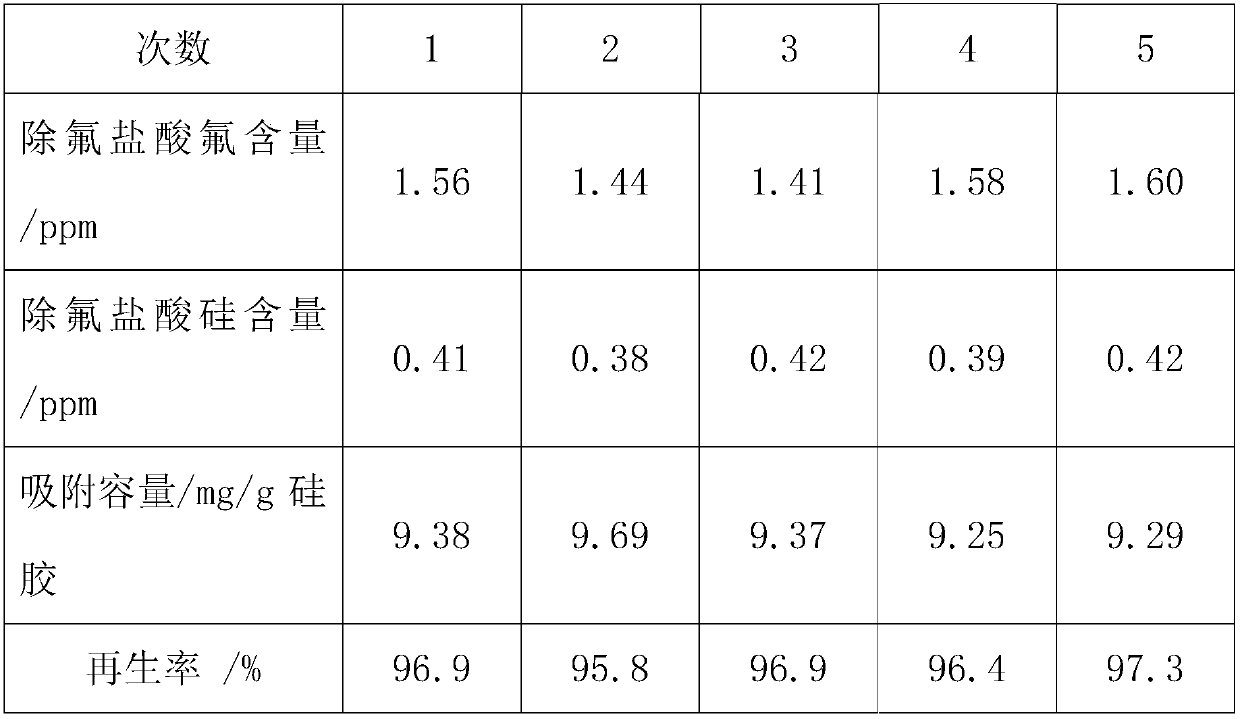

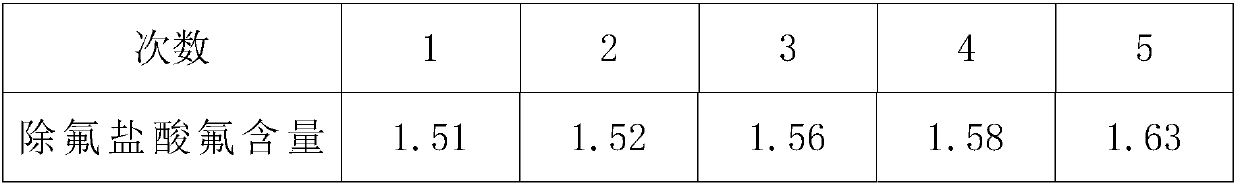

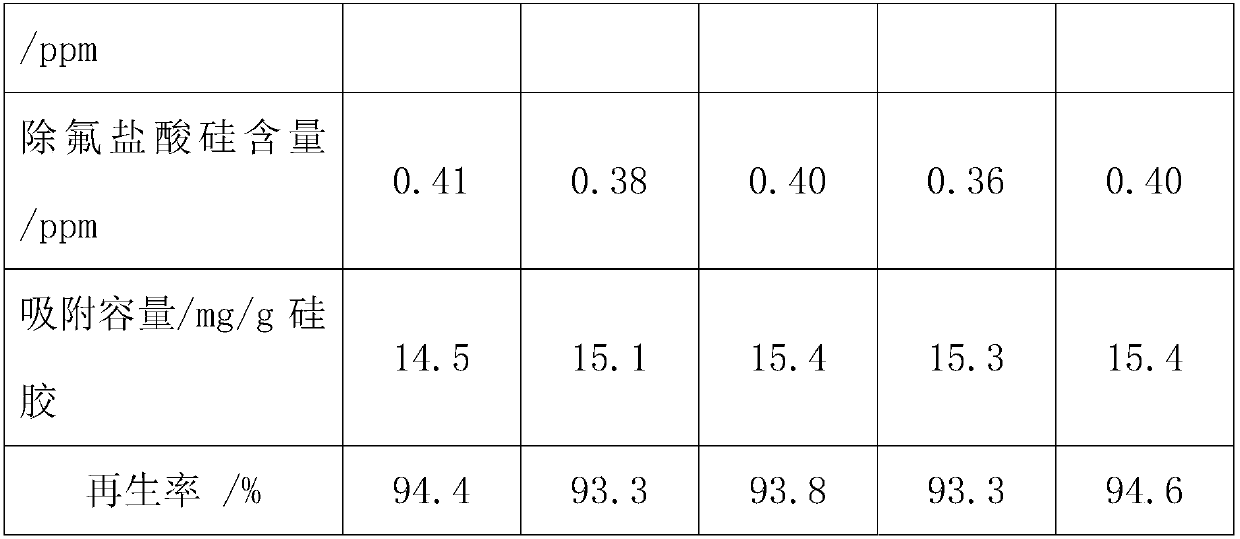

[0034] (1) Put 36 grams (50ml) of fine-pore silica gel with a particle size of 2-4mm in the air for 24 hours to absorb water until saturated, fill it into an adsorption column with an inner diameter of 15mm, and use a peristaltic pump to pump fluorine-containing hydrochloric acid (fluorine content 53.5ppm) Pour into the adsorption column from the top at a flow rate of 50ml / h, carry out adsorption defluorination at 25°C, collect the effluent wastewater from the bottom, and take samples to analyze the fluorine content. When the fluorine content of the effluent reaches about 3ppm, stop acid feeding, drain the hydrochloric acid in the adsorption column, collect the hydrochloric acid after defluorination, measure the fluorine and silicon content, and calculate the adsorption capacity.

[0035] (2) Next, regenerate with distilled water, use a peristaltic pump to pump 1500g of regenerant into the adsorption column from the top at a flow rate of 50ml / h, flow out from the bottom to coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com