Supported platinum complex oxidizing agent easy to recycle and preparation method and application thereof

A platinum complex and oxidant technology, which is applied in the field of supported platinum complex oxidant and its preparation, can solve the problems of inability to recycle and reuse, complicated recovery operation, etc., and achieves simple recovery and regeneration treatment, simple preparation and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

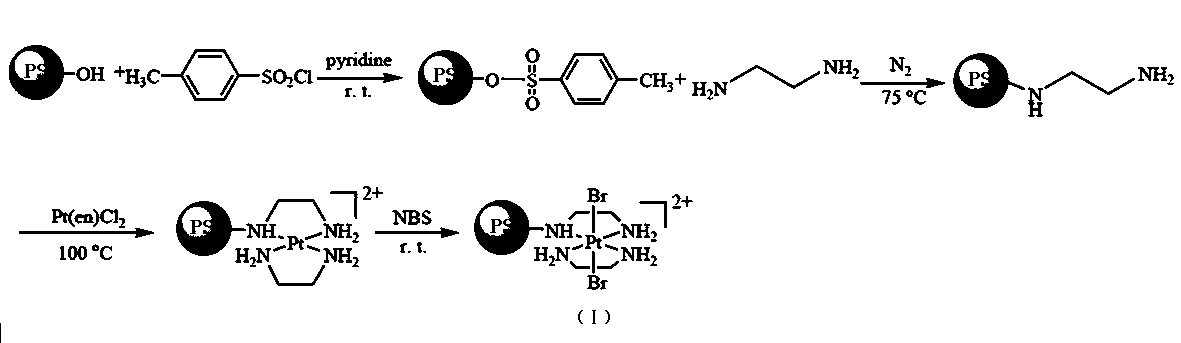

Method used

Image

Examples

Embodiment 1

[0051] The polystyrene microspheres used in this example are commercially available, with a particle size of 110 μm.

[0052] ①In a 250 mL three-necked flask, add 1.0 g of polystyrene microspheres and 100 mL of anhydrous pyridine, then add 5 g of p-toluenesulfonyl chloride, stir magnetically, and react at room temperature for 3 days; after the reaction is completed, filter and wash the obtained solid with ethanol 5 times, then 50 o C vacuum drying 12h, obtains the polystyrene microsphere of p-toluenesulfonyl modification of yellow;

[0053] ②Add 1.0g p-toluenesulfonyl-modified polystyrene microspheres into a 100mL three-necked flask, then add 50mL ethylenediamine, stir with magnetic force, 60 o C reaction 2d; after the reaction is completed, filter, and wash the solid with ethanol 3 times, then vacuum-dry to obtain dark yellow ethylenediamine-modified polystyrene microspheres;

[0054] ③Weigh 0.2g of ethylenediamine-modified polystyrene microspheres into a 100mL three-neck f...

Embodiment 2

[0059] The polystyrene microspheres used in this example are commercially available, with a particle size of 75 μm.

[0060] ①In a 250 mL three-necked flask, add 1.0 g of polystyrene microspheres and 100 mL of anhydrous pyridine, then add 5 g of p-toluenesulfonyl chloride, stir magnetically, and react at room temperature for 2 days; after the reaction is completed, filter and wash the obtained solid with ethanol for 5 times, then 50 o C vacuum drying 12h, obtains the polystyrene microsphere of p-toluenesulfonyl modification of yellow;

[0061] ②Add 1.0g p-toluenesulfonyl-modified polystyrene microspheres into a 100mL three-necked flask, then add 50mL ethylenediamine, stir with magnetic force, 60 o C reaction 1d; after the reaction is completed, filter, wash the solid 3 times with ethanol, and then vacuum-dry to obtain dark yellow ethylenediamine-modified polystyrene microspheres;

[0062] ③Weigh 0.2g of ethylenediamine-modified polystyrene microspheres into a 100mL three-nec...

Embodiment 3

[0065] The polystyrene microspheres used in this example are commercially available, with a particle size of 320 μm.

[0066] ①In a 250 mL three-necked flask, add 1.0 g polystyrene microspheres and 150 mL anhydrous pyridine, then add 5 g p-toluenesulfonyl chloride, stir magnetically, and react at room temperature for 3 days; after the reaction is completed, filter and wash the obtained solid with ethanol for 5 times, then 50 o C vacuum drying 12h, obtains the polystyrene microsphere of p-toluenesulfonyl modification of yellow;

[0067] ②Add 1.0g p-toluenesulfonyl-modified polystyrene microspheres into a 100mL three-neck flask, then add 80mL ethylenediamine, stir with magnetic force, 80 o C reaction 2d; after the reaction is completed, filter, and wash the solid with ethanol 3 times, then vacuum-dry to obtain dark yellow ethylenediamine-modified polystyrene microspheres;

[0068] ③Weigh 0.2g of ethylenediamine-modified polystyrene microspheres into a 100mL three-neck flask, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com