Preparation method of carbon nano tube and graphene hybrid reinforced metal matrix composite

A technology of carbon nanotubes and composite materials, which is applied in the field of preparation of carbon nanotubes and graphene hybrid reinforced metal matrix composite materials, can solve the problems of poor dispersion of carbon nanotubes, achieve convenient and effective process methods, short process, The effect of increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

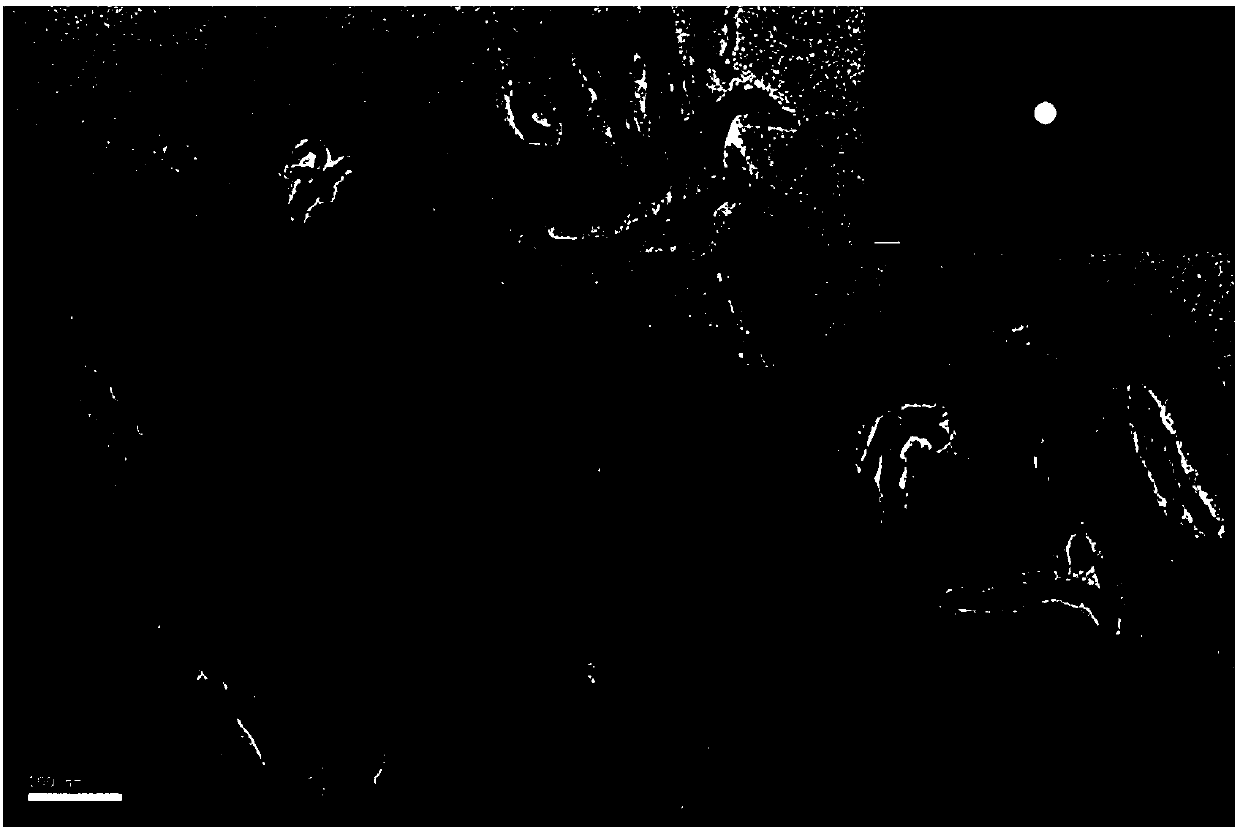

Image

Examples

Embodiment 1

[0029] (1) Weigh 100 mg of graphene oxide and 500 mg of carbon nanotubes into 60 ml of deionized water, and ultrasonicate the mixture at room temperature for 20 min, accompanied by mechanical stirring. The above mixed dispersion was placed in a drying oven at a temperature of 200° C. and a drying time of 7 hours. The dried solid was taken out and placed in a tube furnace for reduction at a temperature of 300° C. and a holding time of 8 hours. The reduced powder was added to 160ml of acetone, and ultrasonicated at room temperature for 20 minutes, accompanied by mechanical stirring.

[0030] (2) Weigh 49.4g of pure magnesium powder and add it to the dispersion liquid obtained in (1), and stir for 40min. Then it was placed in a vacuum drying oven at a drying temperature of 70° C. for 180 minutes. The dried powder was subjected to extrusion molding, the extrusion temperature was 350° C., and the extrusion ratio was 10.

Embodiment 2

[0032] (1) Weigh 700 mg of graphene oxide and 100 mg of carbon nanotubes into 80 ml of distilled water, and ultrasonicate the mixture at room temperature for 60 min, accompanied by mechanical stirring. The above mixed dispersion was placed in a drying oven at a temperature of 80° C. and a drying time of 24 hours. The dried solid was taken out and placed in a tube furnace for reduction at a temperature of 400° C. and a holding time of 6 hours. Add the reduced powder into 180ml of absolute ethanol, and ultrasonicate at room temperature for 60min, accompanied by mechanical stirring.

[0033](2) Weigh 49.2 g of aluminum alloy (1060) powder and add it to the dispersion obtained in (1), and stir for 120 min. Then it was placed in a vacuum drying oven at a drying temperature of 85° C. for 120 minutes. The dried powder was subjected to extrusion molding, the extrusion temperature was 400° C., and the extrusion ratio was 10.

Embodiment 3

[0035] (1) Weigh 100 mg of graphene oxide and 900 mg of carbon nanotubes and add them into 100 ml of distilled water, and ultrasonicate the above mixture at room temperature for 120 min, accompanied by mechanical stirring while ultrasonicating. The above mixed dispersion was placed in a drying oven at a temperature of 150° C. and a drying time of 12 hours. The dried solid was taken out and placed in a tube furnace for reduction at a temperature of 500° C. and a holding time of 5 hours. Add the reduced powder into 200ml of absolute ethanol, and ultrasonicate at room temperature for 120min, accompanied by mechanical stirring.

[0036] (2) Weigh 49.0 g of titanium alloy (TA22) powder and add it to the dispersion obtained in (1), and stir for 90 min. Then it was placed in a vacuum drying oven at a drying temperature of 100° C. for 80 minutes. The dried powder was subjected to extrusion molding, the extrusion temperature was 500° C., and the extrusion ratio was 16.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com