Rapid-heat-storage high-strength phase change energy storage composite structural member and preparation process thereof

A phase change energy storage and composite structure technology, applied in the field of materials, can solve the problems of poor mechanical properties, slow heat storage of phase change material structural parts, etc., and achieve good mechanical properties, good sealing, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

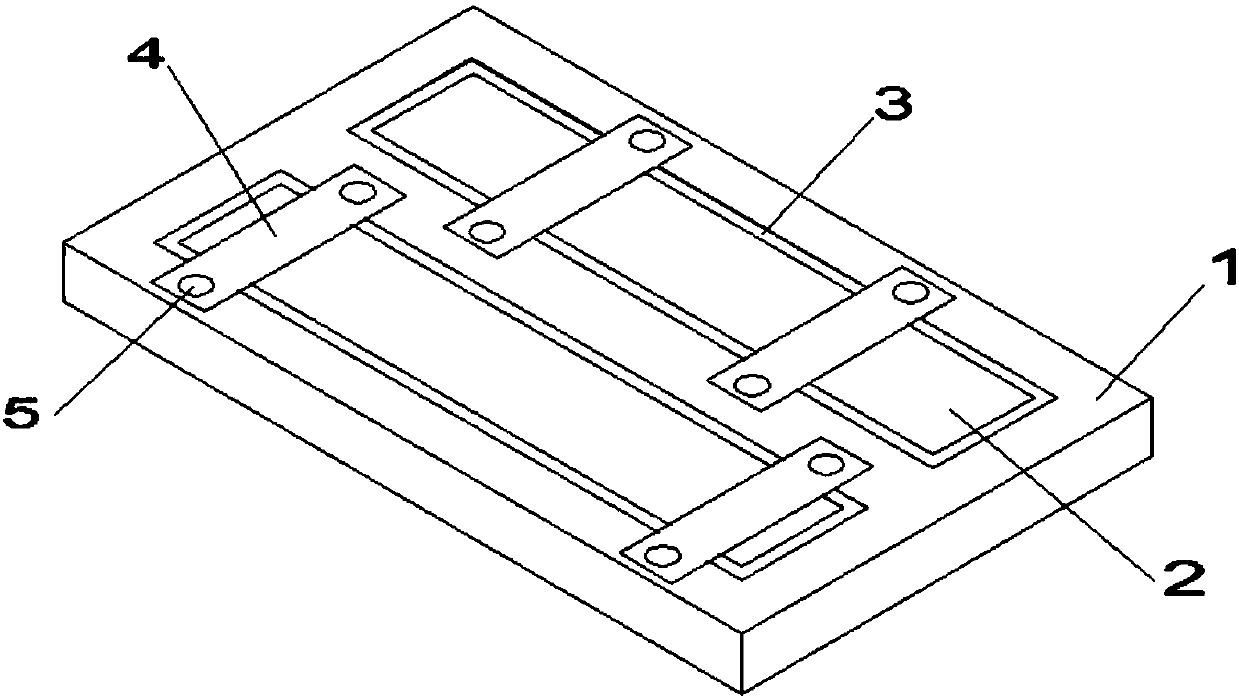

[0050] Step 1, process the aluminum alloy into a concave frame with screw holes by casting, the thinnest part is 2mm, and the thermal conductivity of the obtained aluminum alloy frame is 160W / (m·K);

[0051] Step 2: heating and melting polyethylene, mixing evenly with phase change material microcapsules and aluminum powder with a phase change temperature of 70°C at 120°C, the mass ratio of polyethylene, phase change material microcapsules, and aluminum powder is 3.5:5.5 : 1. The plate-type phase change energy storage structural part is obtained by mold forming, and its appearance size corresponds to the concave aluminum alloy skeleton, so that it can be installed in the aluminum alloy skeleton. The thermal conductivity of the obtained phase change energy storage structural part is 2W / (m K);

[0052] Step 3: Bond the phase-change energy storage structure to the aluminum alloy frame with a 5W heat-conducting phase-change sheet, and fix it with stainless steel sheets and screws. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com