Silicon carbide-graphite shell-and-tube heat exchanger

A tube-and-tube heat exchanger, silicon carbide graphite technology, which is applied in the types of heat exchangers, heat exchanger shells, indirect heat exchangers, etc. Small, easy to assemble, high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following embodiments may enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention to the scope of the described embodiments.

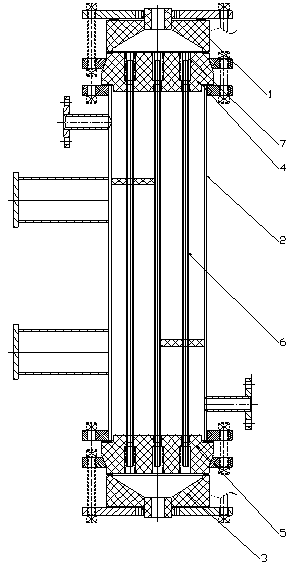

[0022] Such as Figure 1-Figure 5 A silicon carbide graphite tube heat exchanger shown, including

[0023] A jacket, including an upper head 1, a middle sleeve 2 and a lower head 3 connected in turn from top to bottom. The upper head 1 has a material inlet, the lower head 3 has a material outlet, and the middle sleeve 2 The upper and lower sides respectively have a circulating water inlet and a circulating water outlet along the diagonal direction.

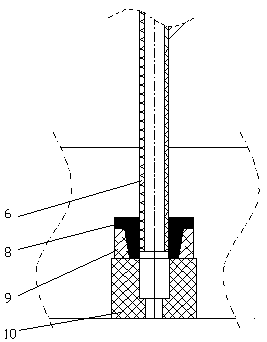

[0024] A graphite lining that cooperates with the outer sleeve to form a heat exchange channel, including an upper tube plate 4 arranged between the upper head 1 and the middle sleeve 2, and a lower tube plate 5 between the lower head 3 and the middle sleeve 2 , The silicon carbide heat exchange tubes 6 arranged side by side bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com