Intelligent wearing jewelry production method and jewelry thereof

A technology of smart wear and manufacturing method, which is applied to the manufacturing method of smart wearable accessories and the field of accessories, can solve the problems that the payment function of the wearable accessories is affected, the normal use of the card is affected, and the aesthetics needs to be improved, so as to avoid the inconvenience of payment and the use of craftsmanship. The effect of feasible, preventable interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

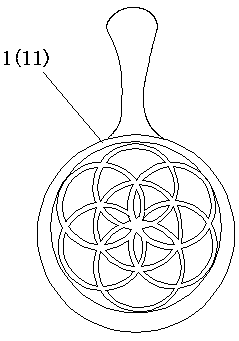

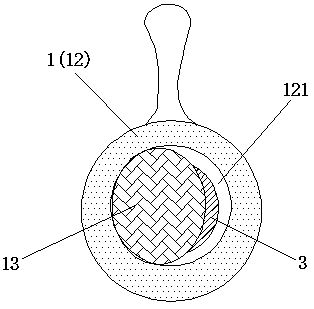

[0035] This embodiment provides a method for manufacturing smart wearable accessories, including the following steps:

[0036] (1) Carry out 3D modeling according to the specific shape and structure of the jewelry customization, and 3D print the initial wax model with cavity on the back;

[0037] (2) Put the initial wax model into gypsum, make the initial wax model cover the gypsum, wait for the plaster to solidify, heat to raise the temperature to 50°C, the initial wax model will melt when heated, become liquid and flow out of the plaster , Forming a cavity in the plaster with the same structure as the initial wax model;

[0038] (3) Pour copper water into the cavity and increase the heating temperature to 700℃ to make the copper water solidify in the gypsum, then dissolve the gypsum to obtain a copper model, and then polish the copper model to meet the requirements of shipping quality ;

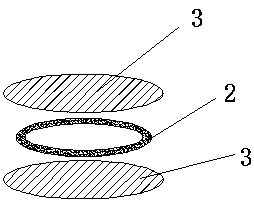

[0039] (4) Make a mold frame, pave the silicone rubber on the bottom of the mold frame, then p...

Embodiment 2

[0047] This embodiment provides a method for manufacturing smart wearable accessories, including the following steps:

[0048] (1) Carry out 3D modeling according to the specific shape and structure of the jewelry customization, and 3D print the initial wax model with cavity on the back;

[0049] (2) Put the initial wax model into plaster, make the initial wax model cover the interior of the plaster, wait for the plaster to solidify, heat to raise the temperature to 60℃, the initial wax model will all melt when heated, become liquid and flow out of the plaster , Forming a cavity in the plaster with the same structure as the initial wax model;

[0050] (3) Pour copper water into the cavity and raise the heating temperature to 1000°C to make the copper water solidify in the gypsum, then dissolve the gypsum to obtain a copper model, and then polish the copper model to meet the requirements of shipping quality ;

[0051] (4) Make a mold frame, place the silicone rubber on the bottom of t...

Embodiment 3

[0059] This embodiment provides a method for manufacturing smart wearable accessories, including the following steps:

[0060] (1) Carry out 3D modeling according to the specific shape and structure of the jewelry customization, and 3D print the initial wax model with cavity on the back;

[0061] (2) Put the initial wax model into plaster, make the initial wax model cover the interior of the plaster, wait for the plaster to solidify, heat to raise the temperature to 55°C, the initial wax model will all melt when heated, become liquid and flow out of the plaster , Forming a cavity in the plaster with the same structure as the initial wax model;

[0062] (3) Pour copper water into the cavity and increase the heating temperature to 850℃ to make the copper water solidify in the gypsum, then dissolve the gypsum to obtain a copper model, and then polish and polish the copper model to meet the requirements of shipping quality ;

[0063] (4) Make a mold frame, place the silicone rubber on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com