A method of processing Chuanbei and Chuanbei preparation

A technology of Chuanbei and thorny rose fruit, which is applied in the field of Chuanbei preparations and processing Chuanbei, which can solve the problems of increased curative effect, large energy consumption, and large differences in optimal process conditions, so as to reduce the loss of alkaloids and cell damage. High wall ratio, effect of inhibiting browning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Chuanbei is processed as follows:

[0038] 1. Purification: the qualified fresh Chuanbei Chinese herbal medicine (F.cirrhosa D.Don) is removed from impurities, washed and dried.

[0039] 2. Put the Chuanbei into a plate, put it in a dryer and dry it at 70°C until its water content is about 8%, then stop drying and cool to room temperature.

[0040] 3. Use a multifunctional pulverizer to coarsely pulverize the dried Chuanbei slices to obtain a 50-mesh Chuanbei coarse powder.

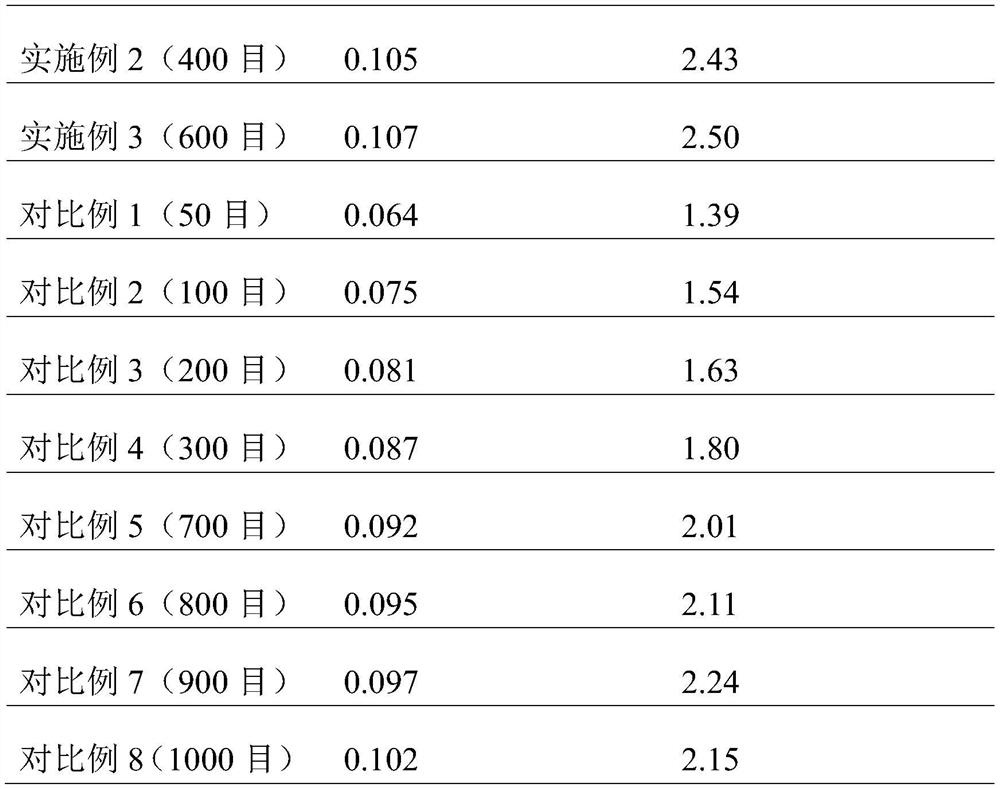

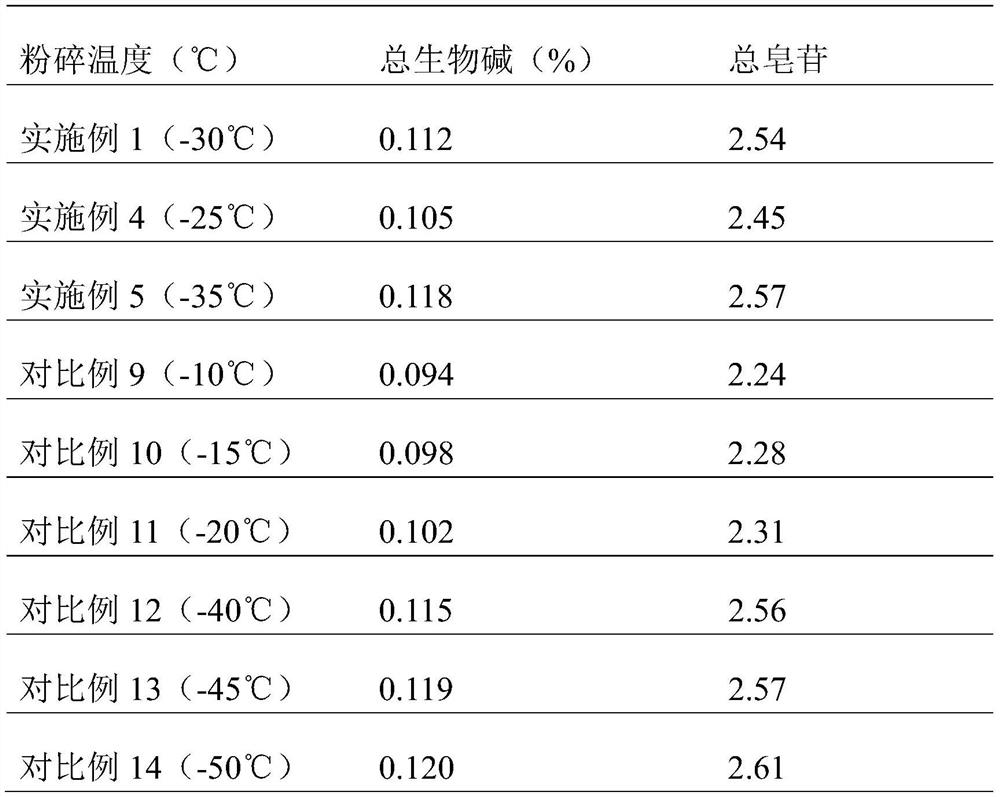

[0041] 4. Carry out ultrafine pulverization to the Chuanbei coarse powder with a vibrating low-temperature ultrafine pulverizer at -30° C., and pulverize to about 500 meshes of Chuanbei superfine powder to a particle size of more than 95%.

[0042] 5. Mix Chuanbei superfine powder evenly, then add 60% volume concentration of ethanol solution as a binder, stir evenly with Chuanbei superfine powder, make a soft material, granulate through a granulator, and dry at 60°C When the water content is lowe...

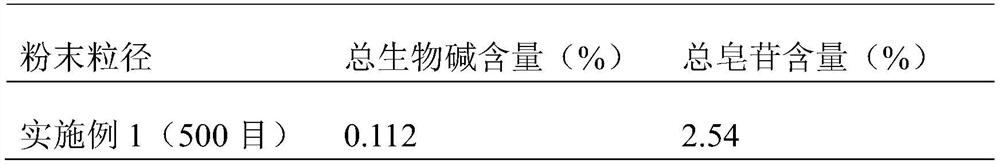

Embodiment 2

[0046] Process Chuanbei by the method described in embodiment 1, difference only is, the particle diameter of more than 95% Chuanbei superfine powder in step 4 is about 400 orders.

Embodiment 3

[0048] Process Chuanbei by the method described in embodiment 1, difference only is, the particle diameter of more than 95% Chuanbei superfine powder in step 4 is about 600 orders.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com