Catalyst for fatty alcohol amination to prepare amine and preparation method thereof

A technology of fatty alcohol amines and catalysts, which is applied in the direction of catalyst activation/preparation, preparation of organic compounds, physical/chemical process catalysts, etc., and can solve problems such as difficult to meet industrial production, catalyst selectivity and low conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

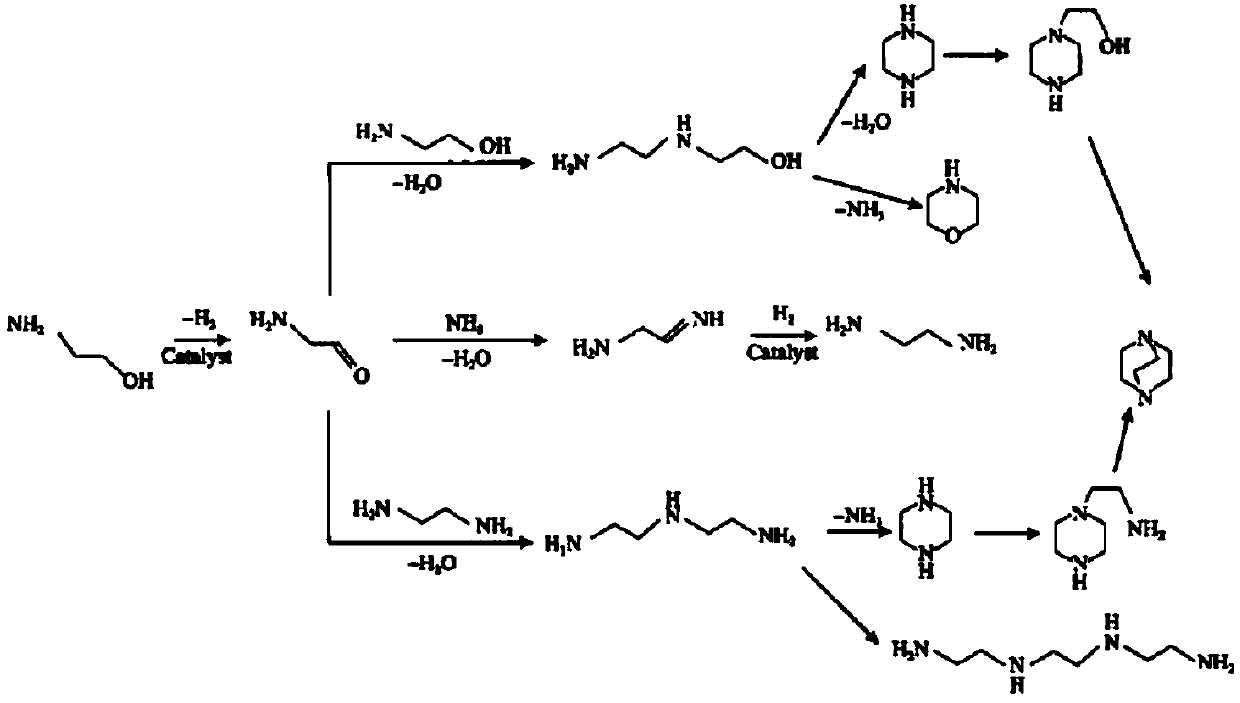

Method used

Image

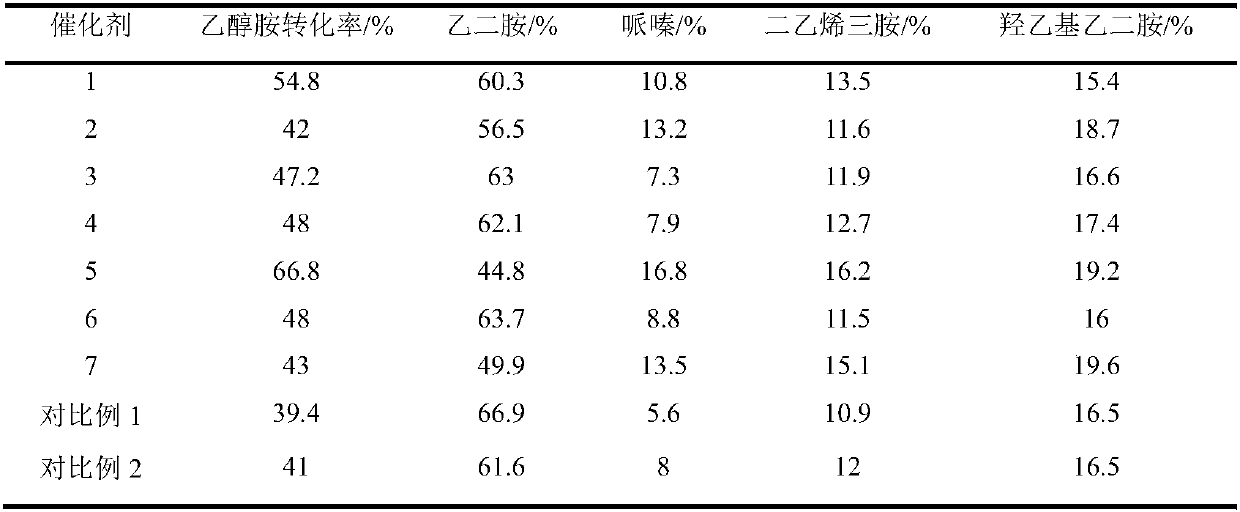

Examples

preparation example Construction

[0020] The preparation method of this catalyst comprises:

[0021] Step S1: treating the carrier with steam, drying it, and performing the first roasting.

[0022] Further, the method of using steam to treat the carrier includes: placing the carrier in a reaction vessel, controlling the reaction vessel at 100-900°C (preferably 500-800°C) and 0.1-3MPa (preferably 0.1-1MPa), and placing the The mixed gas of water vapor and nitrogen is passed into the reaction vessel and treated for 10-24 hours. Further, the water vapor content in the mixed gas is 10-100%, or 20-80%, or 30-60%, or 40-50%.

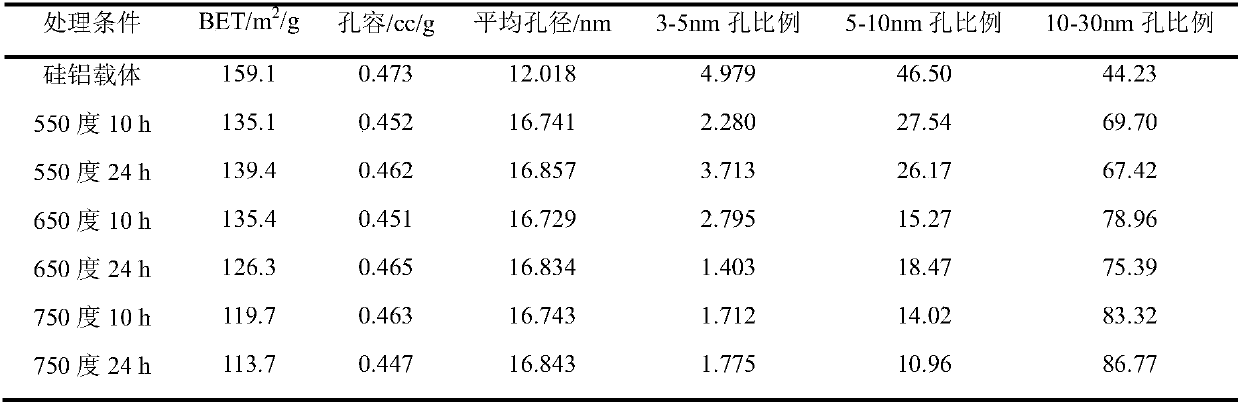

[0023] Using the method of treating the carrier with the above water vapor, different processing temperatures and processing times were selected, taking silicon-aluminum oxide as an example, the surface properties of the carrier under different processing conditions were analyzed, as shown in Table 1:

[0024] Table 1. Surface properties of carriers under different treatment conditions

[0...

Embodiment 1

[0043] This embodiment provides a catalyst for the amination of fatty alcohols to produce amines, which is: 10% Ni-10% Co-2.5% Re-0.5% Ru-1.5% B;

[0044] The preparation method of above-mentioned catalyst is:

[0045] Put the silicon-aluminum oxide carrier in the reaction vessel, control the reaction vessel at 650°C and 0.5 MPa, pass the mixed gas of water vapor and nitrogen (the content of water vapor is 45%) into the reaction vessel, and process After drying for 18 hours, it was calcined at 550°C for 4 hours to obtain the treated silica-alumina carrier.

[0046] Weigh 5g of the silicon-alumina carrier after the above treatment, dissolve 2.47g nickel nitrate hexahydrate, 2.47g cobalt nitrate hexahydrate, 3.0ml ethylenediamine and 0.18g ammonium perrhenate, 0.05g ruthenium chloride, 0.43g boric acid in Dissolve in 10ml of water at 50°C to obtain an impregnating liquid; add half of the impregnating liquid evenly to the silica-alumina carrier, dry at room temperature, dry in a...

Embodiment 2

[0048] This embodiment provides a catalyst for the amination of fatty alcohols to produce amines, which is: 10% Ni-15% Cu-2.5% Pt-1.5% K;

[0049] The preparation method of above-mentioned catalyst is:

[0050] Put the silicon-aluminum oxide carrier in the reaction vessel, control the reaction vessel at 500°C and 0.1 MPa, and pass the mixed gas of water vapor and nitrogen (the content of water vapor is 40%) into the reaction vessel, and treat After drying for 16 hours, bake at 400° C. for 5 hours to obtain the treated silica-alumina carrier.

[0051] Weigh 5g of the silicon-aluminum carrier after the above treatment, dissolve 2.47g of nickel nitrate hexahydrate, 2.9g of copper nitrate trihydrate, 3.6ml of ethylenediamine, 0.22g of platinum chloride, and 0.19g of potassium nitrate in 10ml of water. Dissolve at 90°C to obtain an impregnating liquid; add half of the impregnating liquid evenly to the silica-alumina carrier, dry at room temperature, dry in an oven at 80°C for 6 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com