Short process composite preparing method for gradient high silicon steel sheet

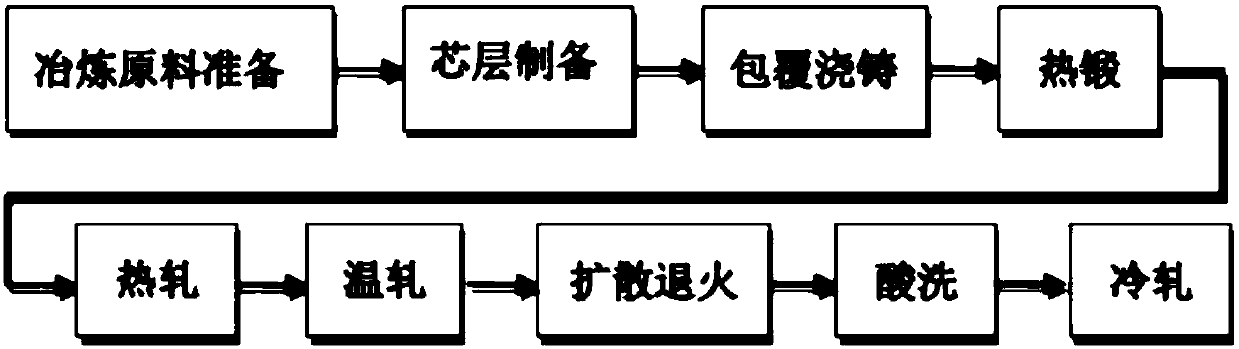

A high-silicon steel, short-process technology, applied in temperature control, metal rolling, manufacturing tools, etc., can solve the problems of complex preparation process, high equipment requirements and high cost of high-silicon steel sheet, to overcome brittle defects and ensure the shape of the plate. Quality, not easy to layer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Raw material preparation: ordinary silicon steel containing about 3% silicon, silicon block containing 99.9% silicon;

[0026] (2) Melting of the core layer: Electromagnetic induction heating furnace is used, the melt temperature is about 1550°C, the silicon content of the core layer is designed to be 10% according to the composition ratio, and the cut length, width and height are (L×W×H)=110×60× 14 (unit: mm) rectangular cube;

[0027] (3) Cladding casting: the cladding layer is ordinary silicon steel containing about 3% silicon, using an electromagnetic induction heating furnace, the melt temperature is about 1500°C, and the thickness of the cladding layer is twice the thickness of the core layer. After cutting off the riser, the high The size of the silicon steel composite slab is (L×W×H)=145×95×70 (unit: mm);

[0028] (4) Forging: Use a small and medium-sized air hammer forging press, heating temperature is 1150°C, heat preservation 50min, forging temperature i...

Embodiment 2

[0035] (1) Raw material preparation: ordinary silicon steel containing about 3% silicon, silicon block containing 99.9% silicon;

[0036] (2) Melting of the core layer: Electromagnetic induction heating furnace is used, the melt temperature is about 1550°C, the silicon content of the core layer is designed to be 10% according to the composition ratio, and the cut length, width and height are (L×W×H)=110×60× 20 (unit: mm) rectangular cube;

[0037] (3) Cladding casting: the cladding layer is ordinary silicon steel containing about 3% silicon, using electromagnetic induction heating furnace, the melt temperature is about 1500°C, and the thickness of the cladding layer is 1.25 times the thickness of the core layer. After cutting off the riser, the high The size of the silicon steel composite slab is (L×W×H)=145×95×70 (unit: mm);

[0038] (4) Forging: Use a small and medium-sized air hammer forging press, heating temperature is 1180°C, heat preservation for 1h, forging temperatur...

Embodiment 3

[0045] (1) Raw material preparation: ordinary silicon steel containing about 3% silicon, silicon block containing 99.9% silicon;

[0046] (2) Core layer smelting: Electromagnetic induction heating furnace is used, the melt temperature is about 1550°C, the silicon content of the core layer is designed to be 11% according to the composition ratio, and the cut length, width and height are (L×W×H)=110×60× 20 (unit: mm) rectangular cube;

[0047] (3) Cladding casting: the cladding layer is ordinary silicon steel containing about 3% silicon, using electromagnetic induction heating furnace, the melt temperature is about 1500°C, and the thickness of the cladding layer is 1.25 times the thickness of the core layer. After cutting off the riser, the high The size of the silicon steel composite slab is (L×W×H)=145×95×70 (unit: mm);

[0048] (4) Forging: Use a small and medium-sized air hammer forging press, heating temperature is 1200°C, heat preservation 70min, forging temperature is 95...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com