A Biofilm Enhanced Nitrogen Removal Process

A treatment process and biofilm technology, applied in biological treatment devices, biological water/sewage treatment, water treatment parameter control, etc., can solve problems such as insufficient microbial biomass in reactors, long process flow, and insufficient sludge concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is elaborated below with the mode of specific embodiment:

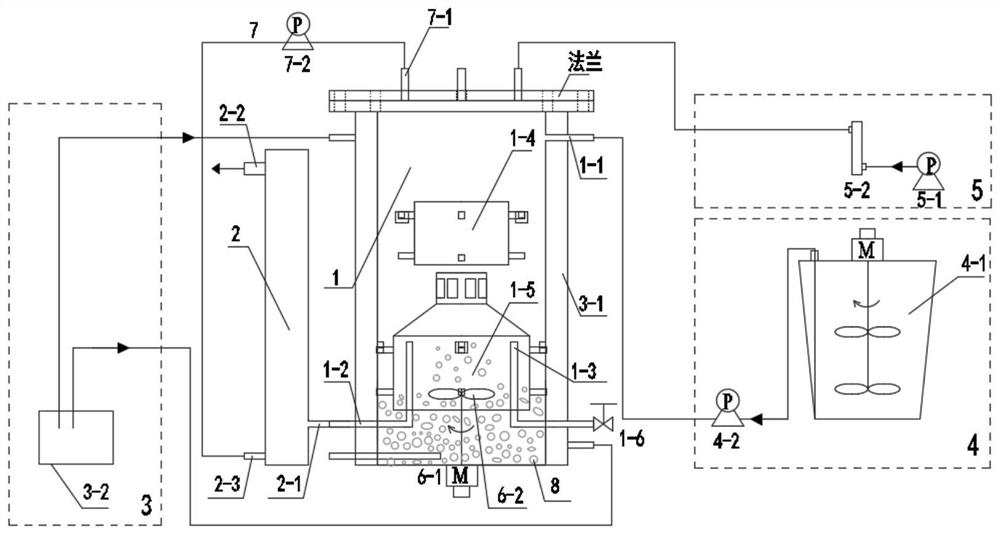

[0037] A biofilm enhanced denitrification treatment process, mainly composed of a biofilm enhanced denitrification device, a constant temperature system, a water inlet system, an aeration system, a stirring system, and a sludge return system. The biofilm enhanced denitrification device is mainly composed of Reactor and sedimentation tank (320mm high, 80mm long, 40mm wide), the main reactor is mainly composed of outer cylinder (250mm in diameter, 340mm in height), top cover (250mm in diameter), inner chamber I and inner chamber II. The interior of the outer cylinder is layered up and down, and the inner cavity I and the inner cavity II are center-symmetrical structures, and are respectively located in the upper and lower layers inside the outer cylinder; the inner cavity I is composed of a hollow cylindrical surface (diameter 88mm) and a peripheral The fixed bracket (length 36mm) is formed,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com