A kind of synthetic method of 2-amino-4-acetamidoanisole

A technology of acetamidoanisole and p-aminoanisole, which is applied in the field of synthesis of 2-amino-4-acetamidoanisole, can solve problems such as increased raw material costs, achieve low equipment corrosion, and avoid raw materials being easy to use. Oxidation, high conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1, synthetic 2-amino-4-acetamidoanisole

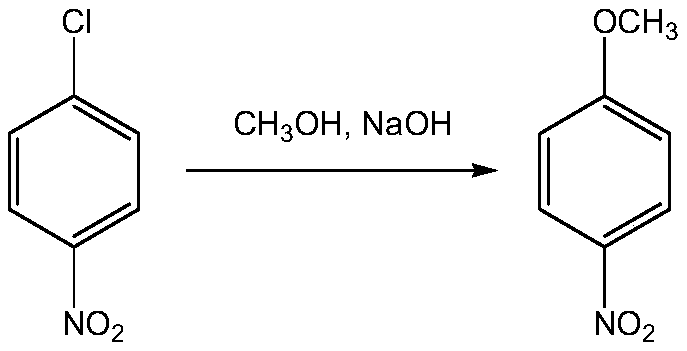

[0063] (1) etherification reaction

[0064] Add 1570kg of p-nitrochlorobenzene and 1920kg of methanol to a 3000L etherification reaction kettle, then raise the reaction temperature to 70°C, gradually add 420kg of sodium hydroxide to it, and carry out the etherification reaction. Heat filtration at 40°C to obtain p-nitroanisole. The yield is 97.2%, and the melting point is 50.5-52.0°C. According to GC analysis, its purity is 99.7%, and the filtrate enters the methanol separation tower, and the methanol is recovered through distillation.

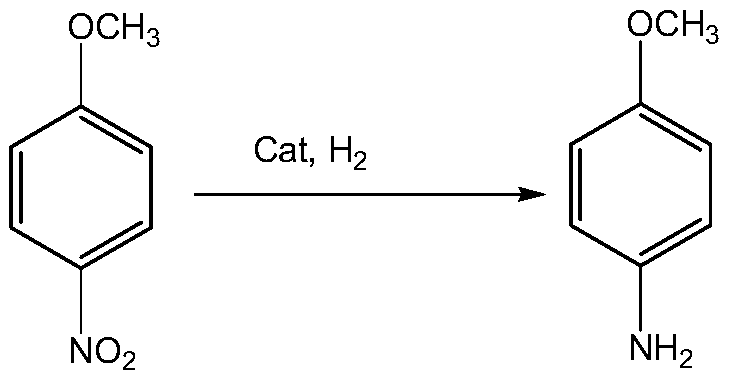

[0065] (2) One catalytic hydrogenation reduction reaction

[0066] With 6000kg p-nitroanisole, 120kg catalyst Ni-Mo-Co-Li (wherein the weight percent of Ni, Mo, Co, Li is 90.0%, 5.0%, 2.0% and 3%, carrier is modified alumina) Add 7500L methanol in the 16000L reactor, feed nitrogen into the reactor, evacuate the air, repeat 5 times, to completely remove the air in the reactor, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com